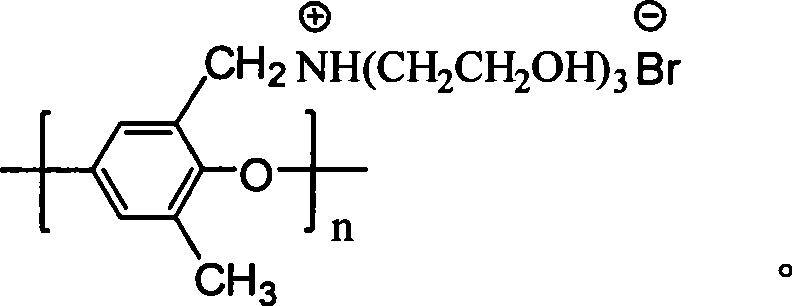

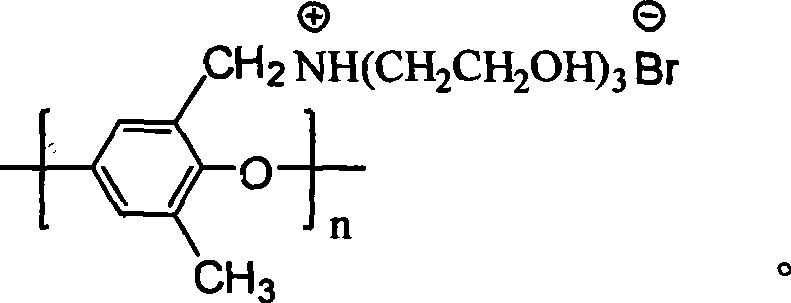

Preparation method of positively charged hyperfiltration membrane and products thereof

An ultrafiltration membrane, positively charged technology, applied in the field of preparation of positively charged ultrafiltration membranes, can solve the problems of high cost, high toxicity, difficult recycling and the like, and achieves improved anti-pollution performance, stable positive charging performance, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Use N-methylpyrrolidone as solvent and triethanolamine as amination reagent to prepare positively charged asymmetric membrane:

[0044] (1) Preparation of casting solution:

[0045] Take 4.2g of benzyl brominated polyphenylene ether and dissolve it in 14.7ml of N-methylpyrrolidone (NMP). After the benzyl brominated polyphenylene ether is completely dissolved, add 0.77ml of polyethylene glycol (PEG-400) To control the porosity of the resulting membrane (the amount added is no more than 10% of the total mass of the casting solution), and stirred into a homogeneous solution;

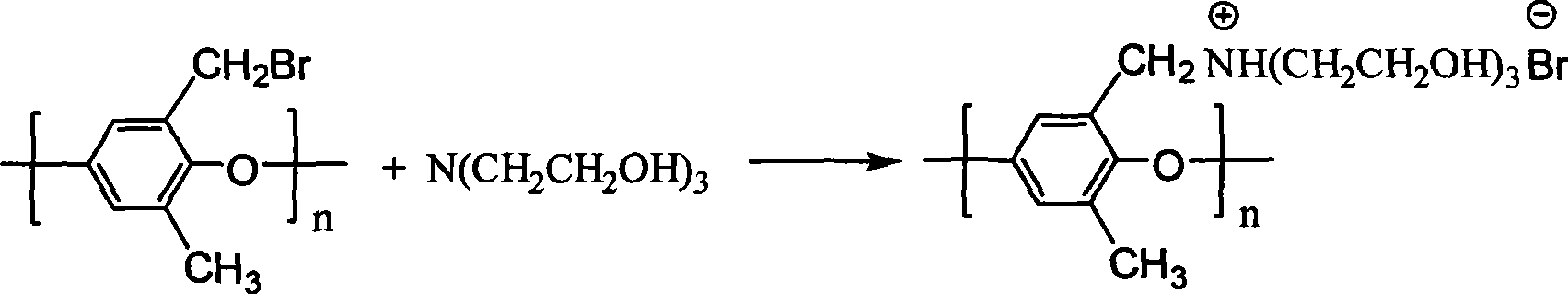

[0046] (2) In-situ amination reaction of casting solution and triethanolamine:

[0047] In the above homogeneous solution, while stirring, a 3.0mol / L triethanolamine NMP solution was added dropwise to it. At this time, the triethanolamine reacted with the benzyl-substituted bromine on the polyphenylene ether to quaternize the membrane material. Positively charged. The molar ratio of the bromine in...

Embodiment 2~4

[0053] Effects of different polyethylene glycol (PEG-400) additions on the prepared positively charged membrane:

[0054] (1) Preparation of casting solution:

[0055] Take 4.2g of benzyl brominated polyphenylene ether and dissolve it in 14.7ml of N-methylpyrrolidone (NMP). After the benzyl brominated polyphenylene ether is completely dissolved, add the additive polyethylene glycol. The amount of polyethylene glycol added It is limited to no more than 10% of the total mass of the casting solution, see Table 1 for details;

[0056] (2) In-situ amination reaction of casting solution and triethanolamine:

[0057] In the above homogeneous solution, while stirring, add the amination reagent triethanolamine to it, and the molar ratio of the bromine in the repeating unit of benzyl brominated polyphenylene ether to the amine in the amination reagent triethanolamine is 8:1. Control the amount of triethanolamine; after the stirring is completed, put it into a water bath at 55°C to rea...

Embodiment 5~7

[0064] Using N-methylpyrrolidone / tetrahydrofuran as a mixed solvent, the influence of different mixing ratios on the prepared positively charged membrane:

[0065] (1) Preparation of casting solution:

[0066] Take 4.2g of benzyl brominated polyphenylene ether and dissolve in 14.7ml of a mixed solvent of N-methylpyrrolidone and tetrahydrofuran, wherein the volume ratio of N-methylpyrrolidone and tetrahydrofuran is shown in Table 2. After completely dissolving, add polyethylene glycol (PEG-400) of 2% of the total mass of the casting liquid, and stir to form a homogeneous solution;

[0067] (2) In-situ amination reaction of casting solution and triethanolamine:

[0068] In the above homogeneous solution, while stirring, add the amination reagent triethanolamine to it, and the molar ratio of the bromine in the repeating unit of benzyl brominated polyphenylene ether to the amine in the amination reagent triethanolamine is 8:1. Control the amount of triethanolamine; after the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com