Ni-reduced austenite stainless steel

An austenitic and stainless steel technology, applied in the field of austenitic stainless steel, can solve the problems of unusable and rising Ni raw material prices, and achieve the effects of good corrosion resistance and excellent reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

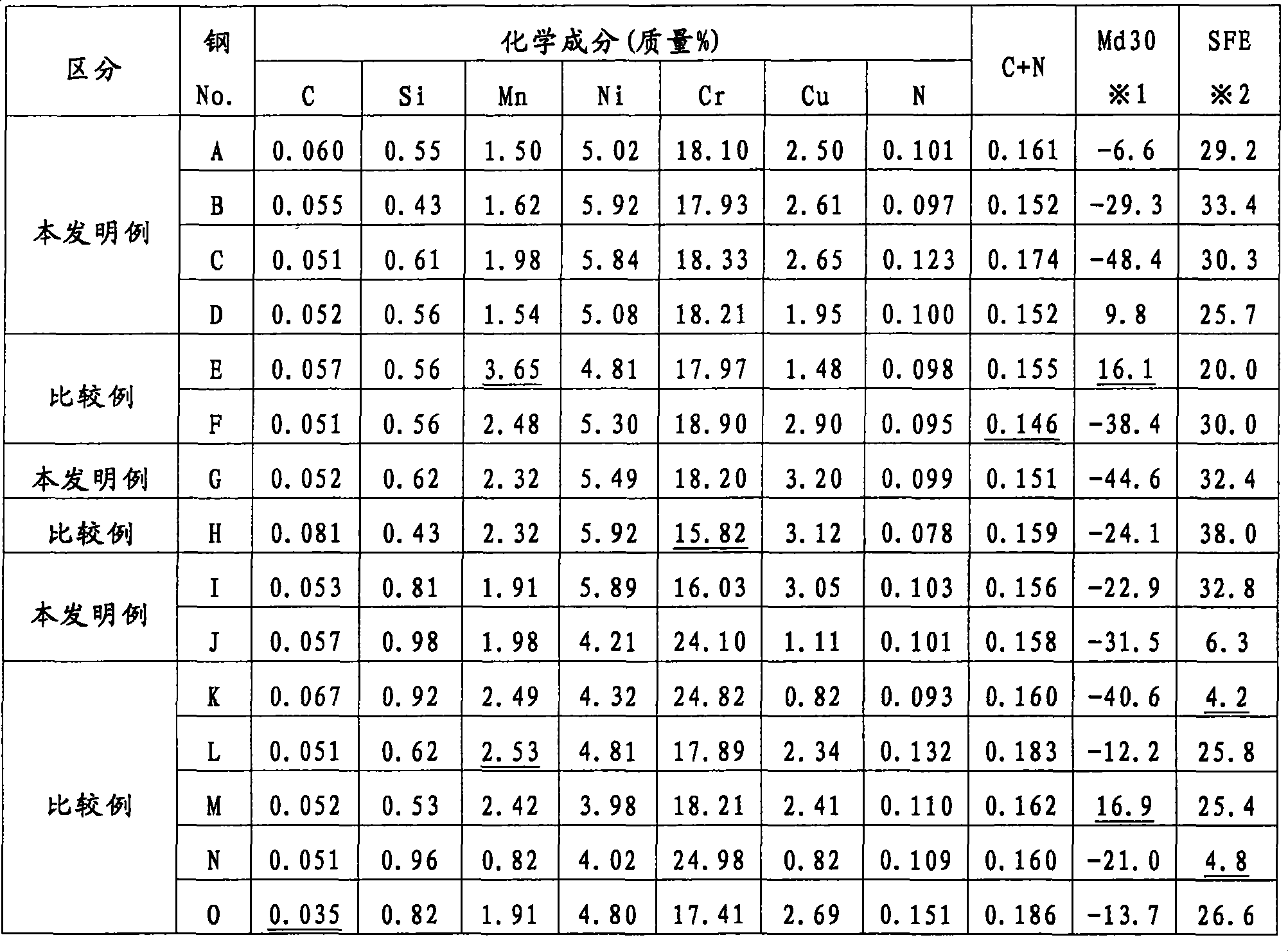

[0046] The austenitic stainless steel having the composition shown in Table 1 was melted to obtain a continuous cast slab, and then hot-rolled at an extrusion temperature of 1230° C. to produce a hot-rolled steel strip having a thickness of 3 mm. After annealing at 1100°C × soaking for 1 minute, the hot-rolled steel strip was cold-rolled to obtain a cold-rolled steel strip with a thickness of 1 mm, and annealing and pickling at 1050°C × soaking for 1 minute were performed to produce annealed and pickled steel. bring.

[0047] Table 1

[0048]

[0049] Underline: outside the scope of the present invention)

[0050] ※1: Md30=551-462(C+N)-9.2Si-8.1Mn-29(Ni+Cu)-13.7Cr

[0051] ※2: SFE=2.2Ni-1.1Cr-13Si-1.2Mn+6Cu+32

[0052] JIS No. 13B test pieces were cut out from steels C, F, G with an Md30 value of about -50 to -40, and steel 0 with an Md30 value of -13.7, respectively, and subjected to a tensile test in a direction parallel to the rolling direction. The gauge length ...

Embodiment 2

[0058] From the annealed and pickled steel strips of the steels A to E and M produced in Example 1, circular plate-shaped billets having various outer diameters at intervals of 2 mm were cut out in the range of outer diameter φ76 to 84 mm, and a deep drawing tester was used. The cup-shaped deep-drawing process is carried out. Using a female mold with an inner diameter Dd of φ43mm and a corner curvature rd of 4mm, and a punch with an outer shape Dp of φ40mm and a corner curvature rp of 3mm, apply a viscosity of 60mm to the surface of the blank in contact with the female mold. 2 / s lubricating oil, under the condition of blank holder force of 5 tons, the formed blank is processed to the deep drawing extension.

[0059] After the molded product was left in the atmosphere at room temperature for 24 hours, the presence or absence of cracks at the edge of the molded product cup was determined, and the natural cracking limit deep drawing ratio of each steel was obtained by the follow...

Embodiment 3

[0067] The pitting corrosion potentials of the steels B, H, and I manufactured in Example 1 were measured according to JIS G0577. The test solution is a 3.5% NaCl aqueous solution, the temperature is 30°C, and the potential is raised from the natural potential with a voltage stabilizer at a scanning speed of 0.33mV / sec, so that the corrosion current in the passivation area becomes 100mA / cm 2 The above potential (mV vs. SCE) was regarded as the pitting corrosion potential. In order to use it as a substitute for a conventional general austenitic stainless steel sheet that is not a Ni-saving type, the pitting corrosion potential is desired to be 200 mV or more of corrosion resistance. The results are shown in Table 4.

[0068] Table 4

[0069] distinguish

steel

No. Cr

(quality%) C+N

(quality%) Md30

pitting corrosion potential

(mV vs SCE) Examples of the present invention B 17.93 0.152 -29.3 235 Comparative example H 15.82 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com