Preparation method for necklace shaped lead titanate nano wire

A lead titanate and nanowire technology, which is applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of uneven particle size distribution, difficult removal of nanowire impurities, and less product volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

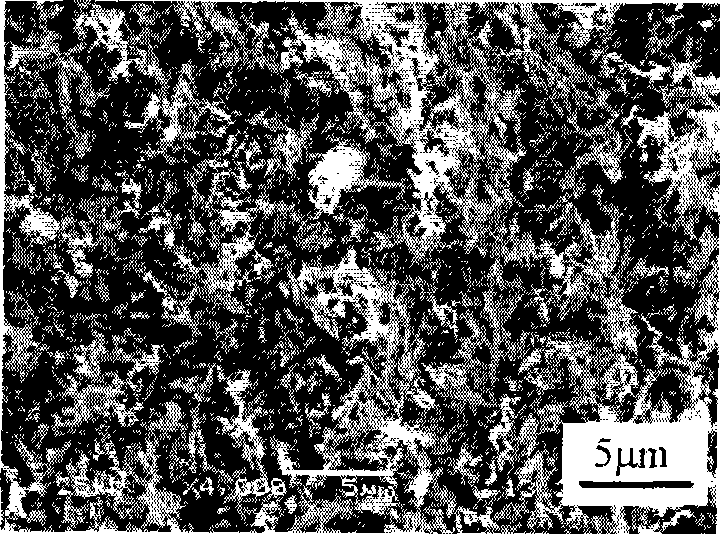

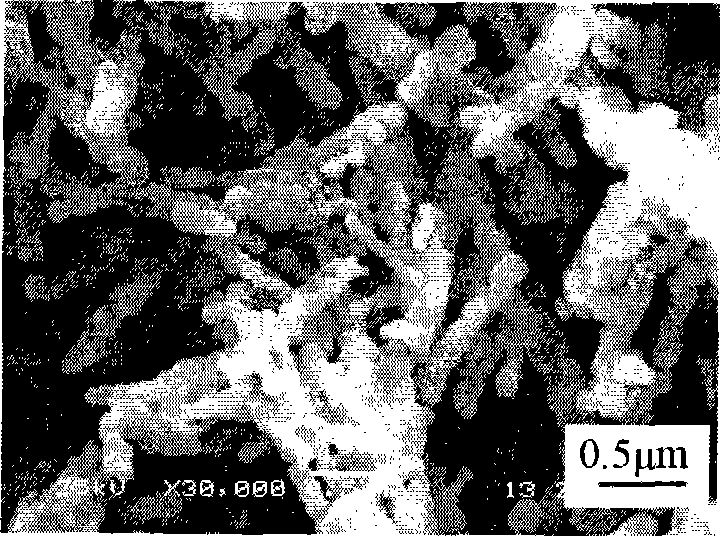

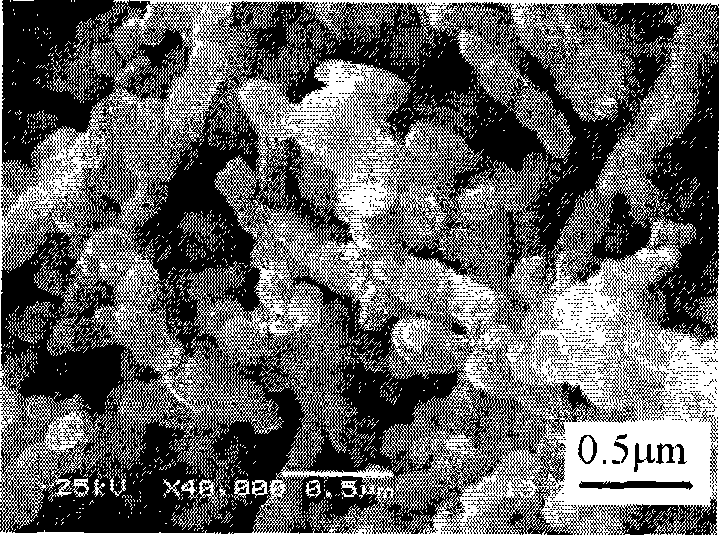

Image

Examples

Embodiment 1

[0027] (1) Accurately weigh 11.09g of H 2 C 2 o 4 2H 2 O is dissolved in deionized water (dubbed into H 2 C 2 o 4 The concentration is 0.88mol / L), add 13.60mL of butyl titanate (the amount of oxalic acid is 2.2 times that of butyl titanate), stir until the solution is clear, transfer it to a 100mL volumetric flask, and adjust the pH value with ammonia water is 3, dilute to the mark with deionized water, and prepare [TiO(C 2 o 4 ) 2 ] 2- solution.

[0028] (2) Take 22mL cyclohexane, 1.13mL octylphenol polyoxyethylene (9) ether (Triton X-100), 1.07mL n-hexanol and 1mL0.42mol / L Pb(NO 3 ) 2 solution (ω 0 =30, P=4.6) into a container, after the components are fully mixed, stir vigorously on a magnetic stirrer for 20 minutes to prepare a uniform and clear Pb-containing 2+ of microemulsions. 1mL0.42mol / L of Pb(NO 3 ) 2 The solution was changed to 1mL0.40mol / L [TiO(C 2 o 4 ) 2 ] 2- Solution, the same amount of other reagents, prepared in the same way containing [Ti...

Embodiment 2

[0031] (1) Accurately weigh 19.66g of H 2 C 2 o 4 2H 2 O is dissolved in deionized water (dubbed into H 2 C 2 o 4 The concentration is 1.56mol / L), add 17.06mL propyl titanate (the amount of oxalic acid is 2.6 times that of propyl titanate), stir until the solution is clear, transfer it to a 100mL volumetric flask, adjust the pH value with ammonia water to about is 2.5, dilute to the mark with deionized water, and prepare [TiO(C 2 o 4 ) 2 ] 2- solution.

[0032] (2) Take 23mL isooctane, 1.26mL alkylphenol polyoxyethylene (10) ether (OP-10), 1.03mL n-octanol and 1mL0.66mol / L PbAc 2 solution (ω 0 =28, P=4.0) into a container, after the components are fully mixed, stir vigorously on a magnetic stirrer for 10 minutes to prepare a uniform and clear Pb-containing 2+ of microemulsions. 1mL0.66mol / L of PbAc 2 The solution was changed to 1 mL of 0.60 mol / L [TiO(C 2 o 4 ) 2 ] 2- Solution, the same amount of other reagents, prepared in the same way containing [TiO(C 2 o...

Embodiment 3

[0035] (1) Accurately weigh 24.71g H 2 C 2 o 4 2H 2 O is dissolved in deionized water (dubbed into H 2 C 2 o 4 The concentration is 1.96mol / L), add 7.69mL titanium tetrachloride (the amount of oxalic acid is 2.8 times that of titanium tetrachloride), stir until the solution is clear, then transfer to a 100mL volumetric flask, adjust the pH value with ammonia water to about is 2.3, dilute to the mark with deionized water, and prepare [TiO(C 2 o 4 ) 2 ] 2- solution.

[0036] (2) Take 21mL of heptane, 1.06mL of octylphenol polyoxyethylene (9) ether (Triton X-100), 1.06mL of n-pentanol and 1mL of 0.71mol / L Pb(NO 3 ) 2 solution (ω 0 =32, P=5.0) into a container, after the components are fully mixed, stir vigorously on a magnetic stirrer for 30 minutes to prepare a uniform and clear Pb-containing 2+of microemulsions. 1mL0.71mol / L of Pb(NO 3 ) 2 The solution was changed to 1 mL of 0.70 mol / L [TiO(C 2 o 4 ) 2 ] 2- Solution, the same amount of other reagents, prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com