Method for producing photon crystal film for improving mechanical strength and solvent resistance

A technology of photonic crystals and solvent resistance, applied in chemical instruments and methods, crystal growth, optics, etc., can solve problems such as narrow application range, and achieve the effect of enhancing mechanical properties and enhancing solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

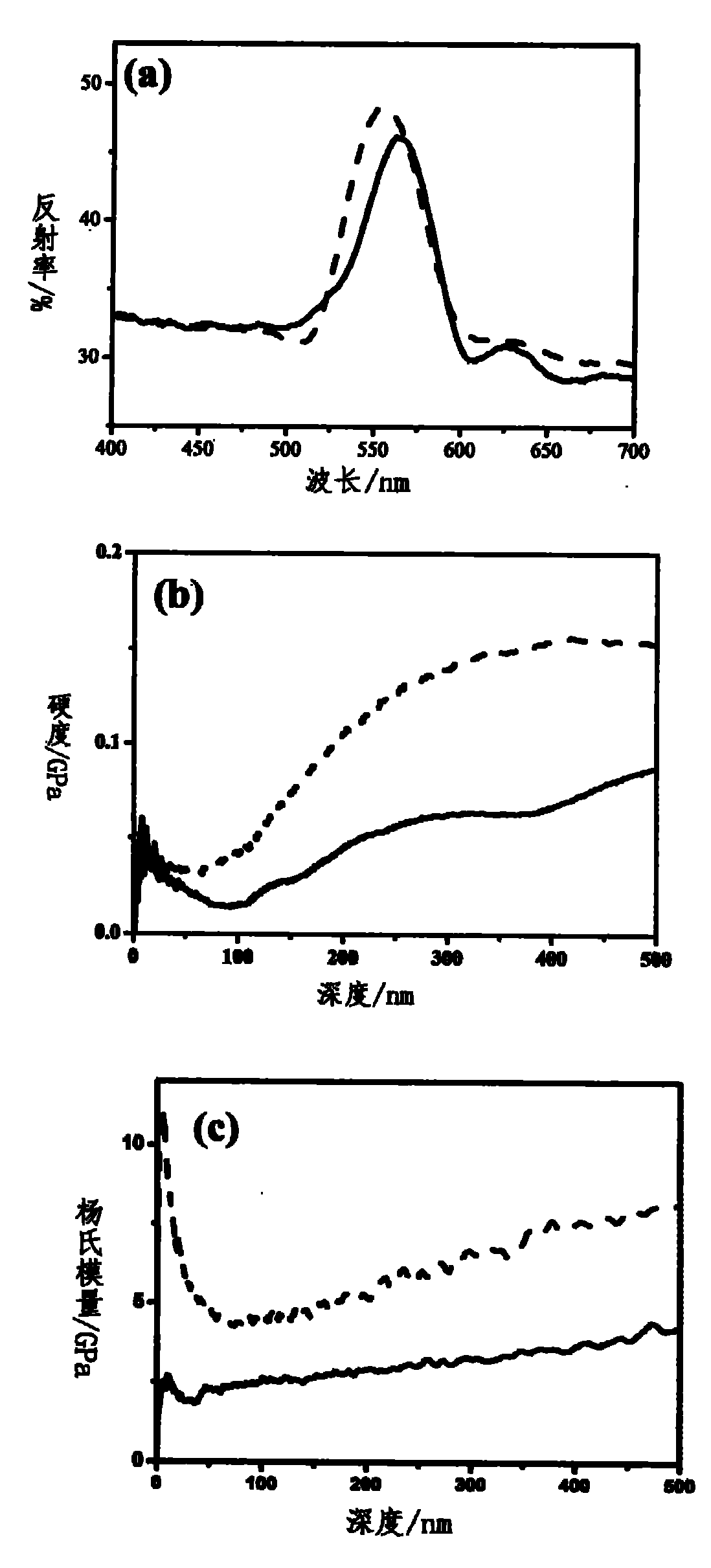

[0027] Pour the polystyrene-methyl methacrylate-acrylic acid triblock copolymer latex pellet emulsion with a mass concentration of 0.2% and a particle size of about 150nm into a small beaker, and insert a clean ordinary glass sheet vertically into it , The water is slowly evaporated in a constant temperature and humidity box with a temperature of 80% and a humidity of 80%, and an opal-type polystyrene-methyl methacrylate-acrylic acid triblock copolymer photonic crystal is obtained on the glass sheet film.

[0028] An ordinary glass sheet with an opal-type structure of polystyrene-methyl methacrylate-acrylic acid triblock copolymer photonic crystal film is immersed in acrylamide with a mass concentration of 5% and diethoxy with a mass concentration of 0.1%. Benzenehexanone, 0.1% by mass concentration of N,N'-methylenebisacrylamide in an aqueous solution for 5 minutes, dry the side without the photonic crystal film, and then cover the side with the opal structure of the photonic cr...

Embodiment 2

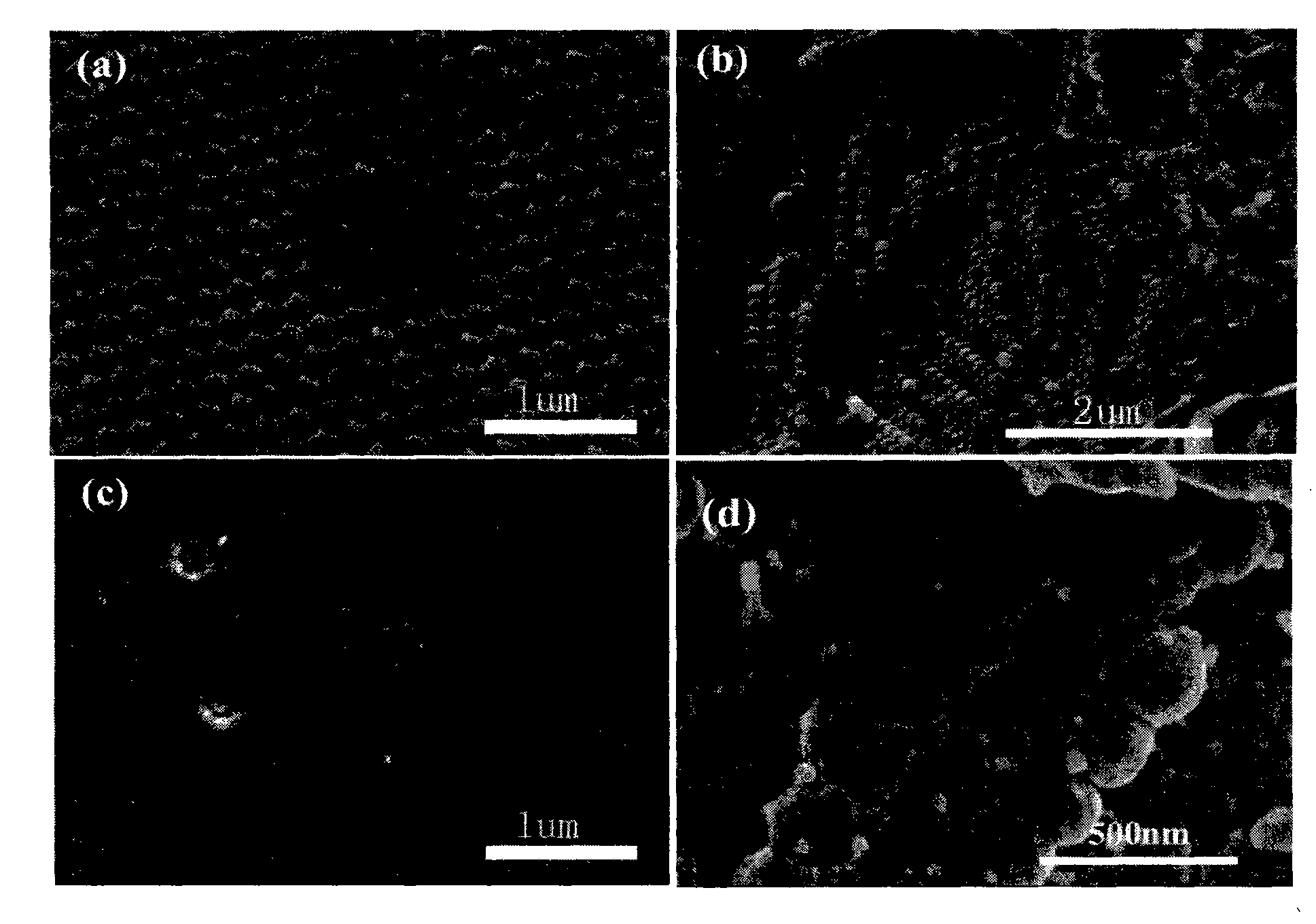

[0034] Pour the polystyrene latex pellet emulsion with a mass concentration of 1% and a particle size of about 240nm into a small beaker, insert a clean ordinary glass sheet vertically into it, and set the temperature to 60°C and humidity to 60% The water is slowly evaporated in the constant temperature and humidity box, and a polystyrene photonic crystal film with an opal structure is obtained on a common glass sheet.

[0035] A common glass sheet with a polystyrene photonic crystal film with an opal structure on one side is immersed in a 2% mass concentration of acrylamide, a mass concentration of 0.06% diethoxyphenhexanone, and a mass concentration of 0.06% N. In the N'-methylenebisacrylamide aqueous solution for 10 minutes, dry the side without the photonic crystal film, and then cover the side of the photonic crystal film with the opal structure on another piece of clean ordinary glass and irradiate it with a UV lamp The photonic crystal film sandwiched between two ordinary ...

Embodiment 3

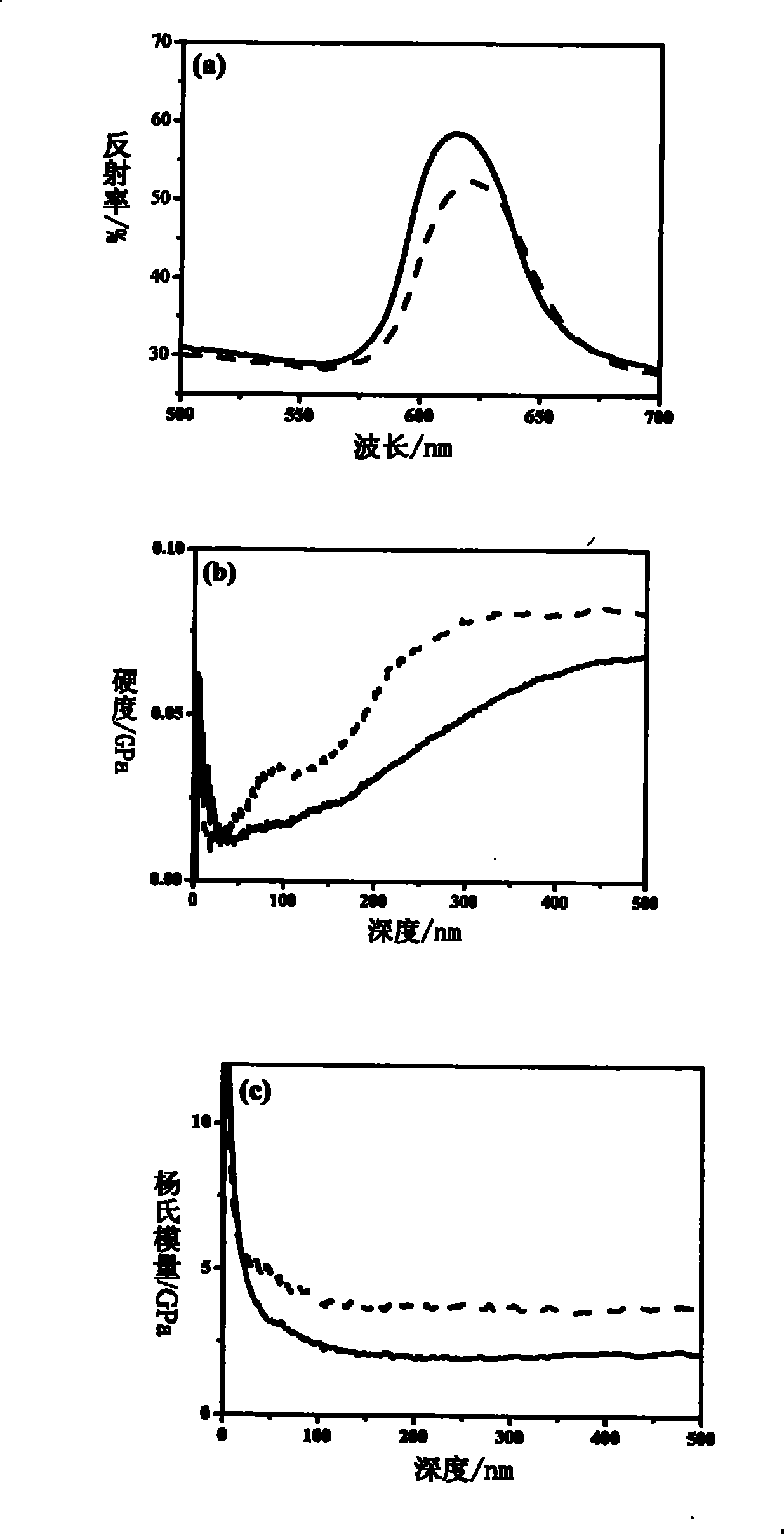

[0041] Pour the ethanol emulsion of silica latex particles with a mass concentration of 0.2% and a particle size of about 250nm into a small beaker, insert a clean ordinary glass sheet vertically into it, and slowly evaporate the ethanol in an oven at a temperature of 36°C , Obtain the opal-type silicon dioxide photonic crystal film on ordinary glass.

[0042] A common glass sheet with a silicon dioxide photonic crystal film with an opal-type structure on one side is immersed in an enamide with a mass concentration of 3%, diethoxyphenhexanone with a mass concentration of 0.03%, and N with a mass concentration of 0.03%. In the N'-methylenebisacrylamide aqueous solution for 1 minute, dry the side without the photonic crystal film, and then cover the side with the opal-shaped photonic crystal film on another piece of clean ordinary glass and irradiate it with a UV lamp The photonic crystal film sandwiched between two ordinary glass sheets polymerizes the polymer monomer; the wavelen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com