Method for preparing large size lithium tetraborate piezoelectric crystal

A lithium tetraborate and piezoelectric crystal technology is applied in the field of preparation of lithium tetraborate piezoelectric crystals, which can solve problems such as crystal cracking, seeding failure, crucible material leakage, etc., so as to reduce crystal cost, improve yield and growth efficiency, The effect of reducing the difficulty of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

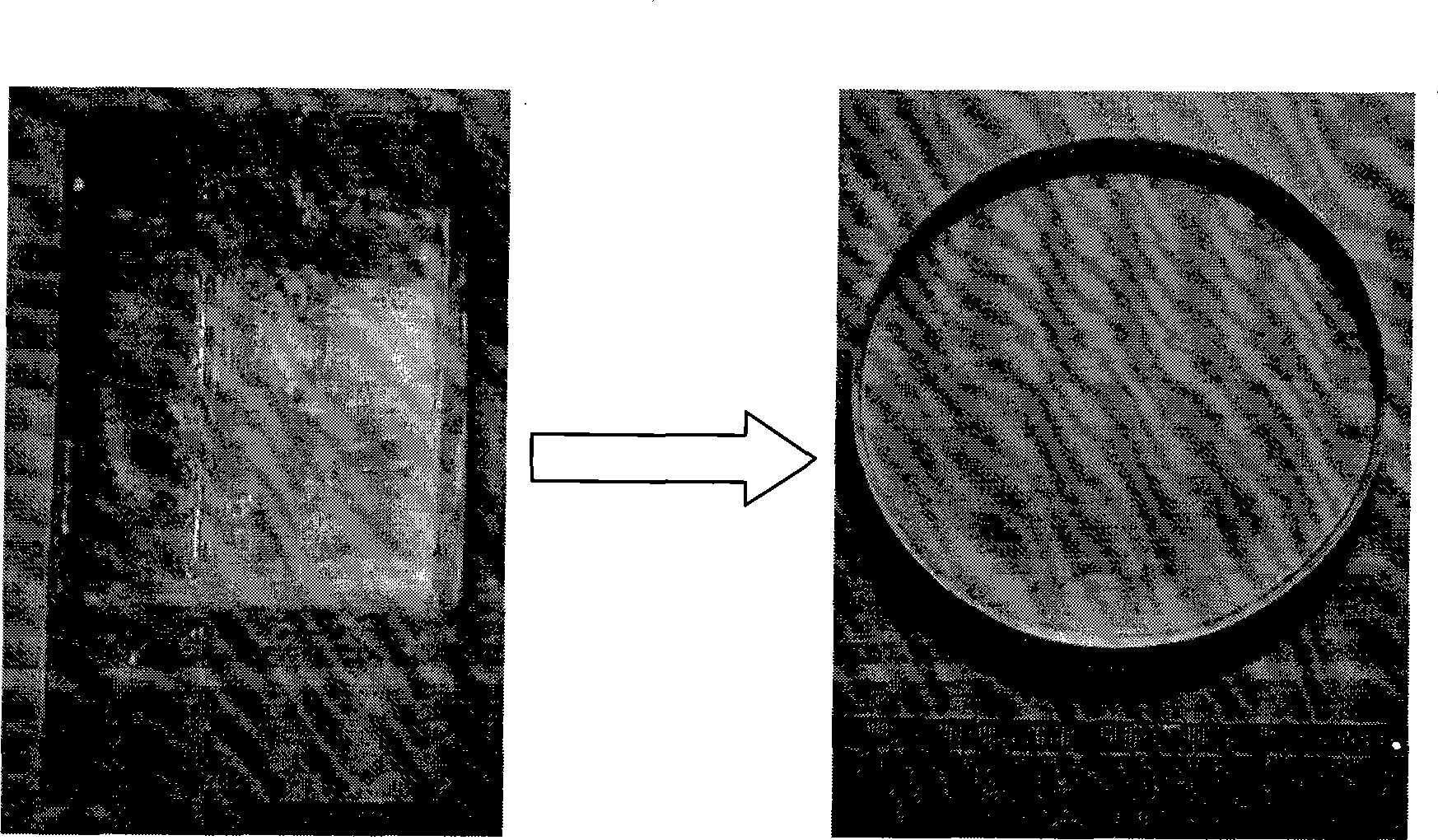

Embodiment 1

[0016] Press 5kg of slightly boron-rich lithium tetraborate polycrystalline material into a dense cylindrical block, and put it into a 60mm×110mm×300mm Pt crucible. A 60mm-long -oriented seed crystal is placed on the bottom of the crucible, and placed The material is placed in a high-temperature zone at an appropriate position in the descending furnace. The furnace temperature is controlled at 950-1000°C, and the crucible descending rate is 0.2mm / h. High-quality large single crystals with a thickness of 60mm, a width of 110mm, and a length of 160mm can be grown. After the growth, the crucible was returned to the constant temperature zone in the furnace, annealed at 800°C for 10 hours, cooled to room temperature, and the crystal was taken out. Accurately orientate along the large side of the crystal, mechanically dig out the cylindrical crystal perpendicular to the surface, and obtain a large-sized lithium tetraborate ingot with a diameter of 4 inches and a thickness of 60 mm. ...

Embodiment 2

[0018] Press 48kg of lithium tetraborate polycrystalline material into dense cylindrical material blocks, and put them into six Pt crucibles with a size of 80mm×120mm×300mm, and place a -oriented seed crystal with a length of 60mm on the bottom of the crucible, and place The raw material is placed in a high-temperature zone at an appropriate position in the descending furnace. The furnace temperature is controlled at 950-1000°C, and the crucible descending rate is 0.4mm / h. Six high-quality large single crystals with a thickness of 80mm, a width of 120mm, and a length of 180mm can be grown. After the growth, the crucible was returned to the constant temperature zone in the furnace, annealed at 800°C for 12 hours, cooled to room temperature, and the crystal was taken out. The crystal is accurately oriented toward the large surface, and the cylindrical crystal is mechanically removed perpendicular to the surface, and 6 large-size lithium tetraborate crystal rods with a diameter of...

Embodiment 3

[0020] Press 6kg of lithium tetraborate polycrystalline material into a dense cylindrical block, put it into a 50mm×160mm×300mm Pt crucible, and place a -oriented seed crystal with a cross-section of 30mm×40mm and a length of 60mm in advance on the bottom of the crucible. Put it in a proper position in the descending furnace so that the raw material is in the high temperature zone, the furnace temperature is controlled at 950-1000°C, and the crucible descending rate is 0.6mm / h. After the growth, the crucible returned to the constant temperature zone in the furnace, annealed at 700°C for 10 hours, slowly lowered the temperature and took out the crucible to obtain a high-quality large single crystal with a thickness of 50mm, a width of 160mm, and a length of 180mm. Accurately orient the crystal laterally to the large surface, mechanically dig out the cylindrical crystal perpendicular to the surface, and obtain a large lithium tetraborate ingot with a diameter of 6 inches and a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com