Blowing, filling, stacking , loading, precipitating, pre-pressing and strong tamping combined soft soil foundation treating method

A technology of soft soil foundation and construction method, applied in basic structure engineering, soil protection, construction and other directions, can solve the problems of long construction period, difficult construction and high construction cost, and achieve the effect of reducing drainage costs, reducing drainage costs and facilitating construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

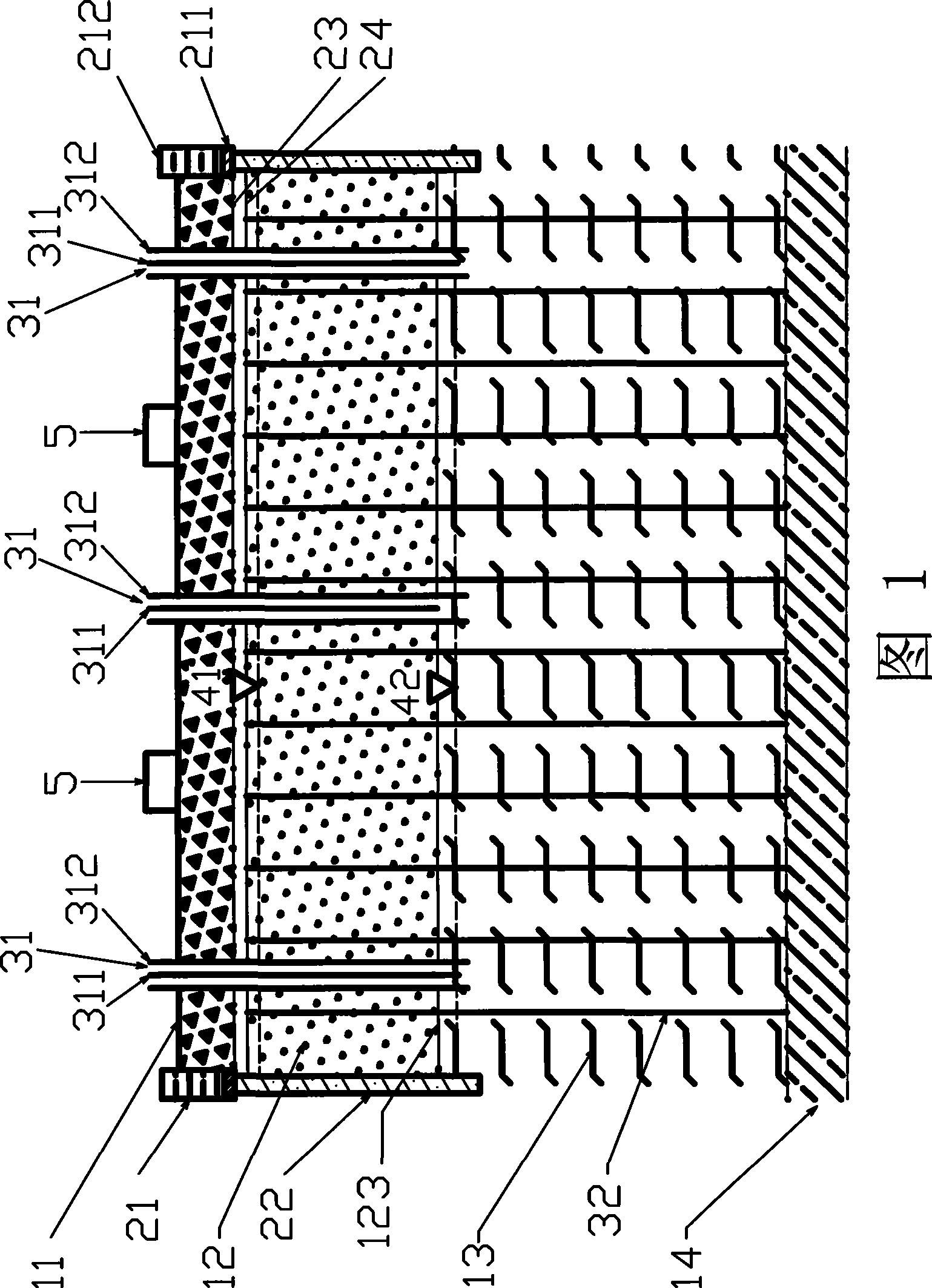

Image

Examples

Embodiment 1

[0064] A seaside soft soil foundation treatment project covers an area of 150,000 square meters, with a surface layer of 5-7 meters of medium-coarse sand and a 10-13-meter layer of silt-like soft soil underneath, with an average water content of 81.3%. .

[0065] Foundation treatment requirements: the bearing capacity of the foundation is not less than 120kpa, the service load is 50kpa, and the post-construction settlement is not more than 25cm. According to the geological conditions of the site, the combined method of preloading and dewatering preloading and dynamic compaction of the present invention is adopted for processing, and the specific technological process is as follows:

[0066] Insert plastic drainage boards to form a grid of 1.1×1.1m, arranged in a square, with a length of 15-19m.

[0067] Tube wells with a diameter of 600mm are laid out in a grid pattern with a spacing of 50×50m, and the length is 7m.

[0068] Divide the site into 5 treatment areas, each wit...

Embodiment 2

[0076] Subgrade project in a beach area, the treatment area is 50000m 2 , the surface layer is 10m thick soft soil layer.

[0077] Firstly, a 2.5m thick artificial sand layer is laid on the soft soil layer.

[0078] Arrange the plastic drainage board with a plugging machine, the length is 13m, forming 1.0×1.0m 2 grid.

[0079] 41 tube wells with a diameter of 550mm and a length of 6.5m are arranged in the sand layer; at the same time, a cofferdam with a thickness of 0.8m and a height of 2.7m is piled up with bagged sand around the treatment area.

[0080] A layer of geotextile and a layer of waterproof membrane are laid on the surface of the artificial sand layer, and the calculated settlement is about 1.2m.

[0081] Then pile up a sand layer with a thickness of 2.7m, and carry out pumping for 60-70 days.

[0082] When the water level drops to 2.5m below the ground, the settlement is about 1.2m. Start strong tamping. The first two times of big tamping can be point tamping...

Embodiment 3

[0085] A land reclamation project in a beach area along the river, with an area of 30,000m 2 , the surface 3m is a medium-fine sand layer, and the underlying soft soil layer is 13m thick.

[0086] Build a mud mixing wall with a thickness of 0.45m and a depth of 3.3m underground around the treatment area at the boundary; use a plug-in machine to arrange plastic drainage boards with a length of 16.5m to form a 1×1m 2 grid.

[0087]15 tube wells with a diameter of 650mm and a length of 6.5m are arranged in the sand layer, and the pumping time is 50-60 days; at the same time, a cofferdam with a thickness of 0.8m and a height of 2.3m is piled up with bagged clay around the treatment area , the calculated settlement is about 2.2m.

[0088] Lay a layer of geotextile and a layer of water-proof membrane on the ground, and then fill the sand layer with a thickness of 2.3m into the cofferdam while pumping water, and carry out preloading and dewatering preloading. The water level drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com