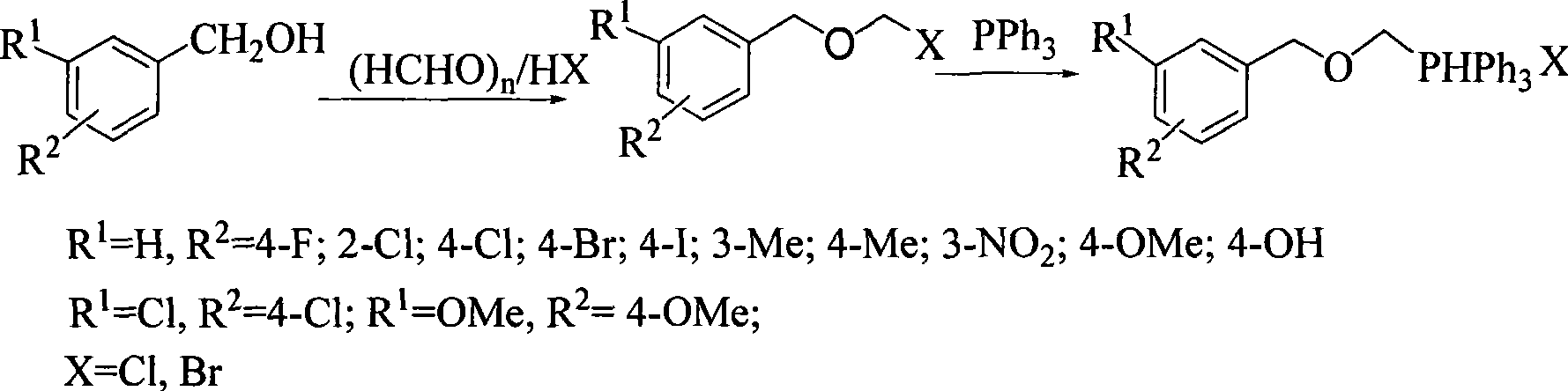

Method for synthesizing triphenylphosphine onium salts and halomethyl benzyl ethers compounds

The technology of a halomethyl benzyl ether and a synthesis method, which is applied in the field of organic compound synthesis, can solve the problems of low yield of triphenylphosphonium salts, low purity of intermediates, decomposition of unstable halogenated hydrocarbons, etc. High efficiency and purity, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a 250 ml three-necked flask, a thermometer and a stirrer were installed, and hydrogen chloride gas (0.12 mol) was passed into benzyl alcohol (0.1 mol) and paraformaldehyde (0.1 mol), and the reaction temperature was controlled to -10°C. It was then stirred at this temperature for 5 hours. Then n-hexane (100ml) was added at room temperature to separate the layers, and the solvent was evaporated under reduced pressure to obtain the product as a light yellow liquid with a yield of 96% and a purity of 99.1area% (HPLC).

Embodiment 2

[0021] In a 250 ml three-necked flask, install a thermometer and a stirrer, feed 4-fluorobenzyl alcohol (0.1mol) and paraformaldehyde (0.15mol) into hydrogen bromide gas (0.15mol), and control the reaction temperature to -5°C . It was then stirred at this temperature for 4 hours. Then n-hexane (120ml) was added at room temperature to separate the layers, and the solvent was evaporated under reduced pressure to obtain the product as a light yellow liquid with a yield of 98% and a purity of 99.6area% (HPLC).

Embodiment 3

[0023] In a 250 ml three-necked flask, a thermometer and a stirrer were installed, and 4-chlorobenzyl alcohol (0.1mol) and paraformaldehyde (0.25mol) were fed into hydrogen chloride gas (0.14mol), and the reaction temperature was controlled at 0°C. It was then stirred at this temperature for 4 hours. Then n-hexane (110ml) was added at room temperature to separate the layers, and the solvent was evaporated under reduced pressure to obtain the product as a light yellow liquid with a yield of 92% and a purity of 99.2area% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com