Method for extracting high-purity epigallocatechin-3-gallate from green tea

A technology of epigallocatechin and gallocatechin, which is applied in the field of extracting and purifying high-purity epigallocatechin gallate, can solve the problems of high price and expensive chemical reagents, and achieve high economic utilization Value, broad market prospects, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

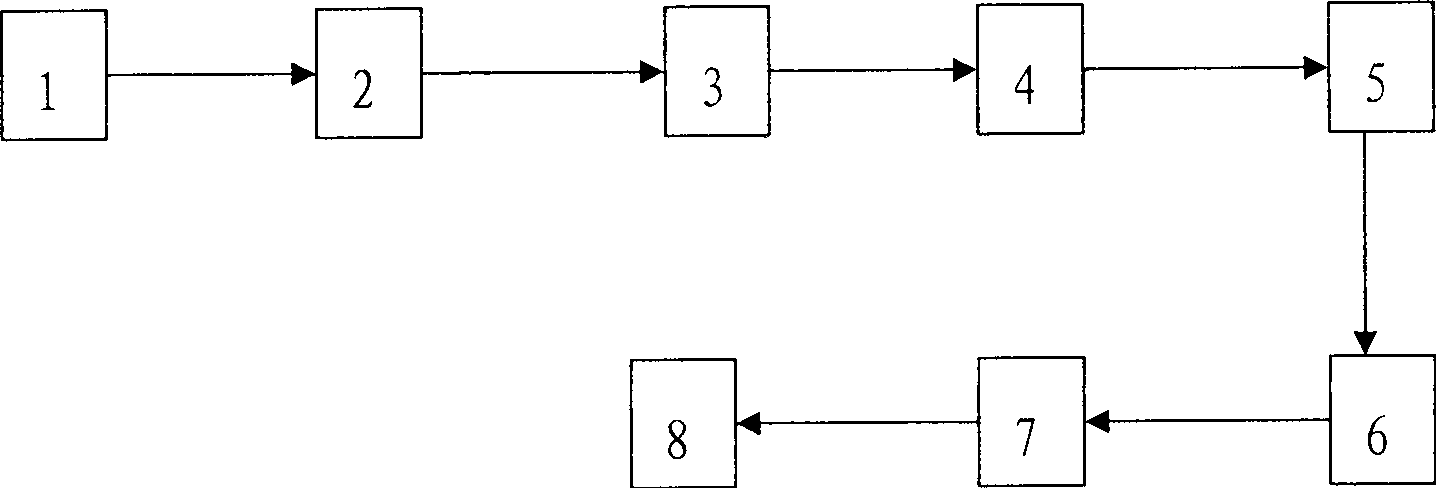

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail through specific examples below.

[0023] (1) Grind the green tea, take 25 grams of tea powder, and put it in a 500ml beaker.

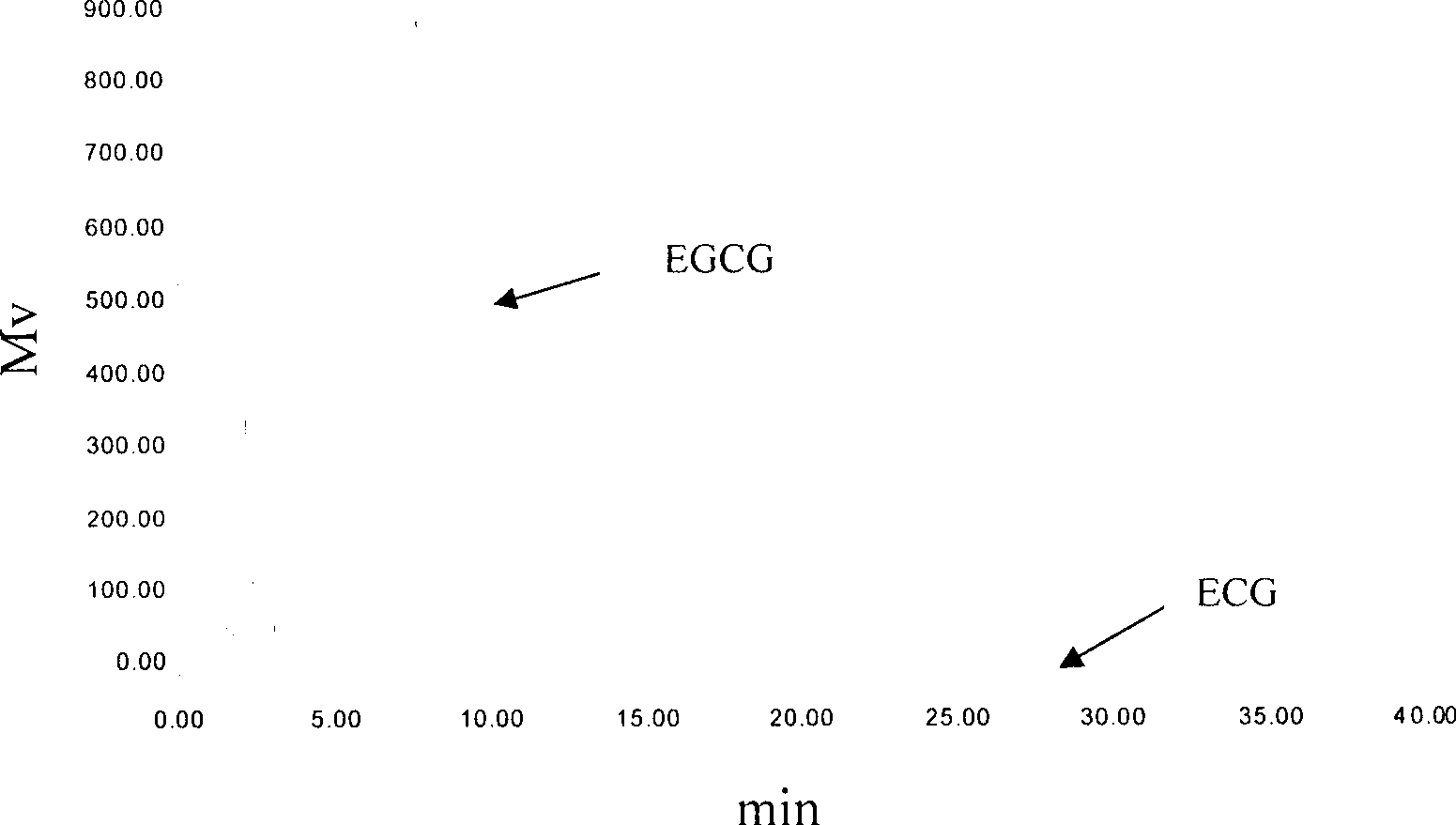

[0024] (2) Add 350ml of double-distilled water, boil for 20-30 minutes, stir once every minute, and filter with suction to obtain tea soup. Add the tea dregs to 350ml of double-distilled water and boil for 20-30 minutes, then filter the tea soup to get the tea soup, combine two tea soups, and the EGCG content detected by high performance liquid chromatography is 30.81% (such as figure 2 ).

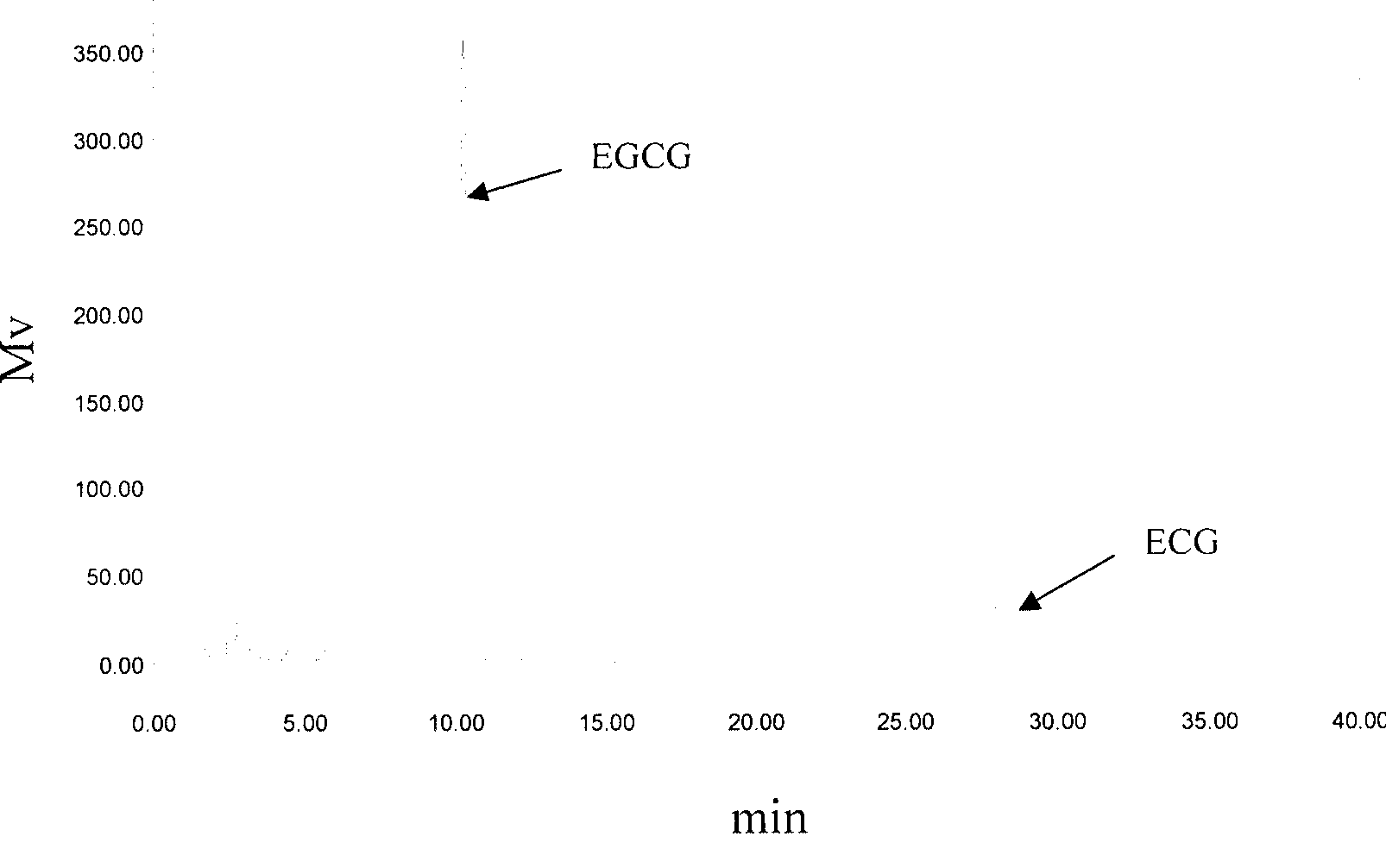

[0025] (3) Put the tea soup in a 1000ml large beaker, keep it warm in a 70°C water bath, add caffeine to 30mmol / L, cool it at room temperature for 1-4 hours after complete dissolution, and cool at 4°C for 0.5-2.0 hours. Centrifuge at 15000g for 30 minutes at 4°C, discard the supernatant, take the precipitate, take 300ml of redistilled water at 60°C to dissolve the precipitate, and transfer the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com