Environment friendly non-halogen reacting fire-retardant aqueous polyurethane and preparation method thereof

A reactive flame-retardant, water-based polyurethane technology, which is applied in the chemical industry, can solve the problems of large smoke generation and accompanying toxic gases, and achieve the effect of transparent coating and low release of volatile solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

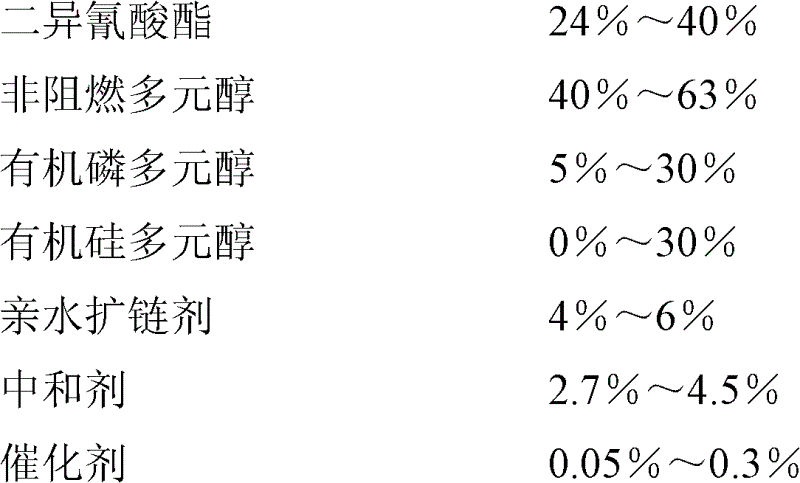

[0028] Environmentally friendly halogen-free flame retardant waterborne polyurethane formula 1.

[0029]

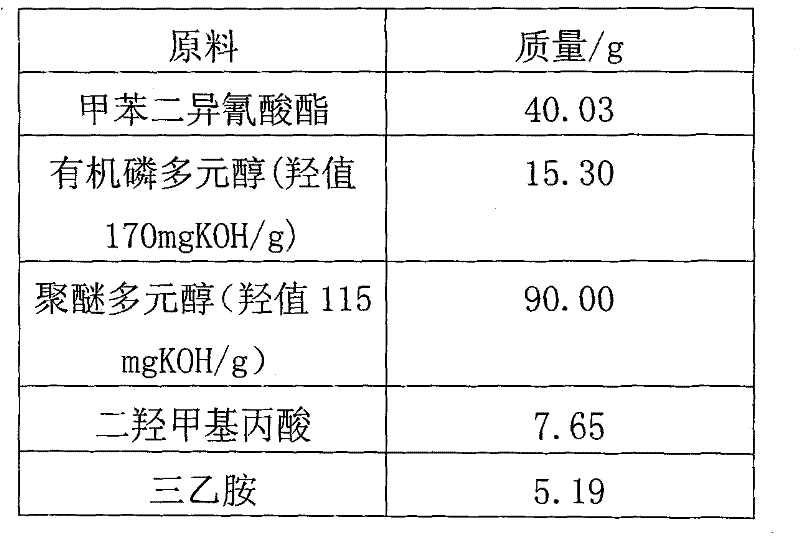

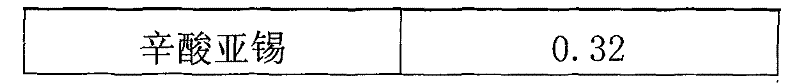

[0030]

[0031] (1) Add polyether polyols, dimethylol propionic acid, toluene diisocyanate, and organic phosphorus with a hydroxyl value of 170 mgKOH / g in a container equipped with an agitator, a reflux condenser, and a thermometer in sequence. polyol and stannous octoate, at 85°C in N 2 React under protection for 8 hours to obtain a prepolymer.

[0032] (2) Cool down the temperature of the prepolymer to 40° C., and add 30 g of butanone to adjust the viscosity of the prepolymer.

[0033] (3) triethylamine is dissolved in 370g deionized water, is made into concentration and is the neutralizer aqueous solution of 1.38%, joins in the prepolymer, carries out emulsification and neutralization wherein with high-speed emulsification equipment immediately, the time is 7 minutes, Then use a rotary evaporator to remove the butanone to obtain a halogen-free waterborne polyur...

Embodiment 2

[0036] Environmentally friendly halogen-free flame retardant waterborne polyurethane formula 2

[0037]

[0038] (1) Add polyether polyol, dimethylol propionic acid, diphenylmethane diisocyanate, hydroxyl value 400mgKOH / g in the container with agitator, reflux condenser, and thermometer successively. g of organophosphorus polyols and stannous octoate, at 85°C in N 2 React under protection for 5 hours to obtain a prepolymer.

[0039] (2) Cool down the temperature of the prepolymer to 40° C., and add 30 g of butanone to adjust the viscosity of the prepolymer.

[0040] (3) triethylamine is dissolved in 483g deionized water, is made into concentration and is the neutralizer aqueous solution of 1.38%, joins in the prepolymer, carries out emulsification and neutralization wherein with high-speed emulsification equipment immediately, the time is 7 minutes, Then use a rotary evaporator to remove the butanone to obtain a halogen-free waterborne polyurethane modified by organophosp...

Embodiment 3

[0043] Environmentally friendly halogen-free flame retardant waterborne polyurethane formula 3

[0044]

[0045] (1) Add polyether polyol, dimethylol propionic acid, toluene diisocyanate, organic polyol with a hydroxyl value of 115mgKOH / g, dimethylol propionic acid, toluene diisocyanate, and a hydroxyl value of 170mgKOH / g in a container equipped with a stirrer, a reflux condenser, and a thermometer. Phosphorus polyols, organosilicon polyols with a hydroxyl value of 53.2mgKOH / g and stannous octoate, at 85°C in N 2 React under protection for 10 hours to obtain a prepolymer.

[0046] (2) Cool down the temperature of the prepolymer to 40° C., and add 40 g of butanone to adjust the viscosity of the prepolymer.

[0047] (3) triethylamine is dissolved in 350g deionized water, is made into 1.44% neutralizer aqueous solution, joins in the prepolymer, carries out emulsification neutralization wherein with high-speed emulsifying equipment immediately, the time is 7 minutes, then with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com