Method for modifying biomass cracked oil to modified bio-oil by quality-improving of esterification and etherification

A technology of biomass pyrolysis oil and esterification ether, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry. It can solve the problems of low calorific value, complex process, unstable physical and chemical properties of biomass pyrolysis oil, etc., and improve the conversion efficiency, corrosion reduction, storage stability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

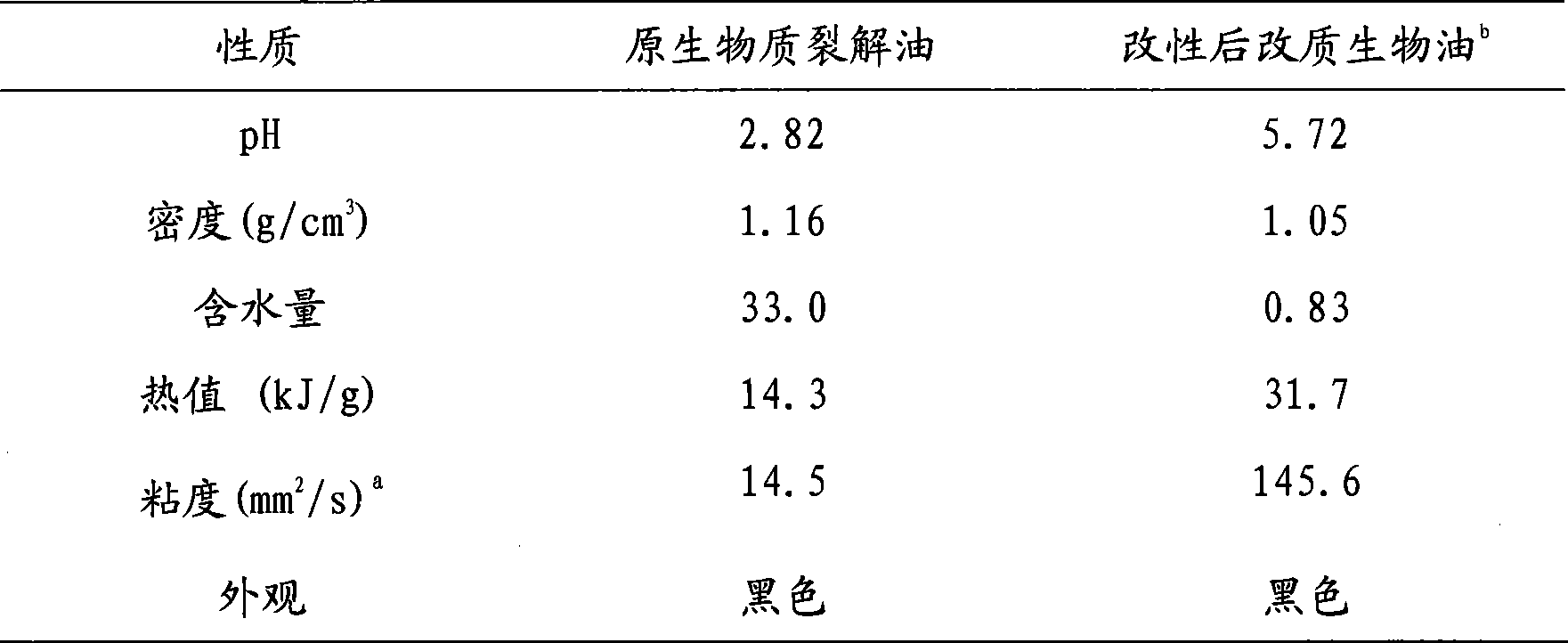

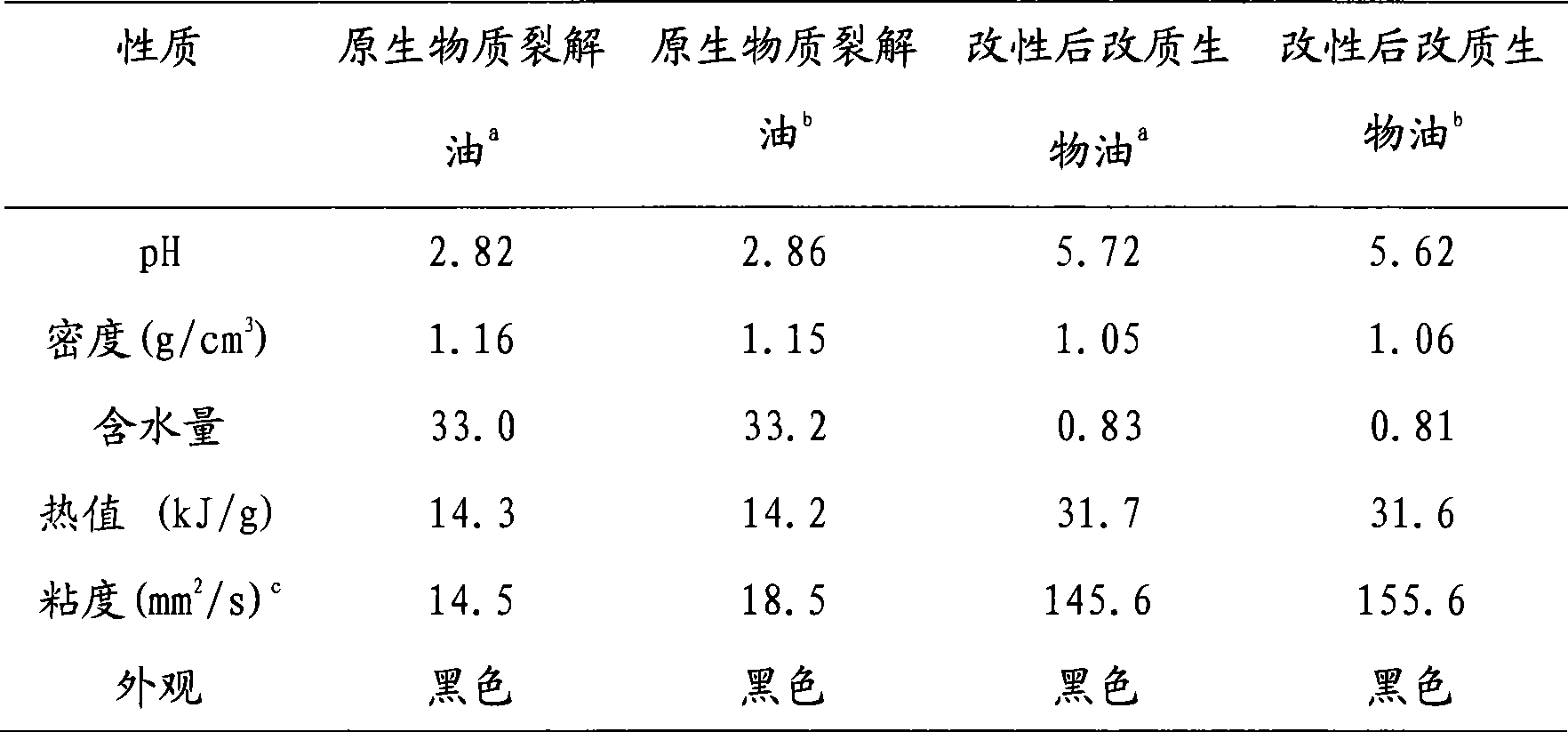

[0022] Add 100g of biomass cracking oil into a four-neck flask equipped with mechanical stirring, condenser and thermometer. The KOH aqueous solution with a mass concentration of 50% was added dropwise, and about 40 g of the aqueous solution was consumed. The obtained mixture is uniform, has good water solubility and no precipitation. Then add 80 g of benzyl chloride and 10 g of absolute ethanol as a homogeneous solvent, and react at 90° C. for 5 h. Static phase separation after the reaction, the lower layer is a clear and transparent KCl aqueous solution; separate the black oil phase of the upper layer, and distill under reduced pressure at 80°C and 10Kpa until there is no distillate to remove residual ethanol and water in the oil phase. At 130-150°C and 10Kpa, after recovering unreacted benzyl chloride, 61g of black viscous liquid was obtained, according to m 产物 :m 乙醇 =3:1 ratio is diluted and dissolved with absolute ethanol to obtain a modified bio-oil with a pH value of...

Embodiment 2

[0024] Add 100g of biomass pyrolysis oil into a four-neck flask equipped with mechanical stirring, condenser, and thermometer. The mass concentration is 50% KOH aqueous solution dropwise, consumes about 80g aqueous solution, and the obtained mixture is uniform, has better water solubility, and has no precipitation. Then add 100 g of benzyl chloride and 20 g of ethanol as a homogeneous solvent, and react at 110° C. for 8 h. Static phase separation after the reaction, the lower layer is a clear and transparent KCl aqueous solution; the black oil phase of the upper layer is separated, and distilled at 80 ° C and 10 Kpa until there is no distillate to remove residual ethanol and water in the oil phase. Distill under reduced pressure at ~150°C and 10Kpa to recover unreacted benzyl chloride to obtain 65g of black viscous liquid, according to m 产物 :m 乙醇 = The ratio of 3:1 is diluted and dissolved with absolute ethanol to obtain a modified bio-oil with a pH of 6.72 and a density of ...

Embodiment 3

[0026]Add 100g of biomass pyrolysis oil into a four-neck flask equipped with mechanical stirring, condenser, and thermometer. The mass concentration of 50% KOH aqueous solution was added dropwise, and about 60 g of aqueous solution was consumed, and the obtained mixture was uniform, had good water solubility, and had no precipitation. Then add 90 g of benzyl chloride and 15 g of ethanol as a homogeneous solvent, and react at 100° C. for 8 h. Static phase separation after the reaction, the lower layer is a clear and transparent KCl aqueous solution; the black oil phase of the upper layer is separated, and distilled at 80 ° C and 10 Kpa until there is no distillate to remove residual ethanol and water in the oil phase. Distill under reduced pressure at ~150°C and 10Kpa to recover unreacted benzyl chloride to obtain 63g of black viscous liquid, according to m 产物 :m 乙醇 = The ratio of 3:1 is diluted and dissolved with absolute ethanol to obtain a modified bio-oil with a pH of 6.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com