Gap tunable triple thin-film solar cell and preparation thereof

A technology of solar cells and thin films, which is applied in the field of adjustable bandgap three-junction thin film solar cells and its production, to achieve the effects of reducing production costs, improving photoelectric conversion efficiency, and reducing reflection and transmission losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

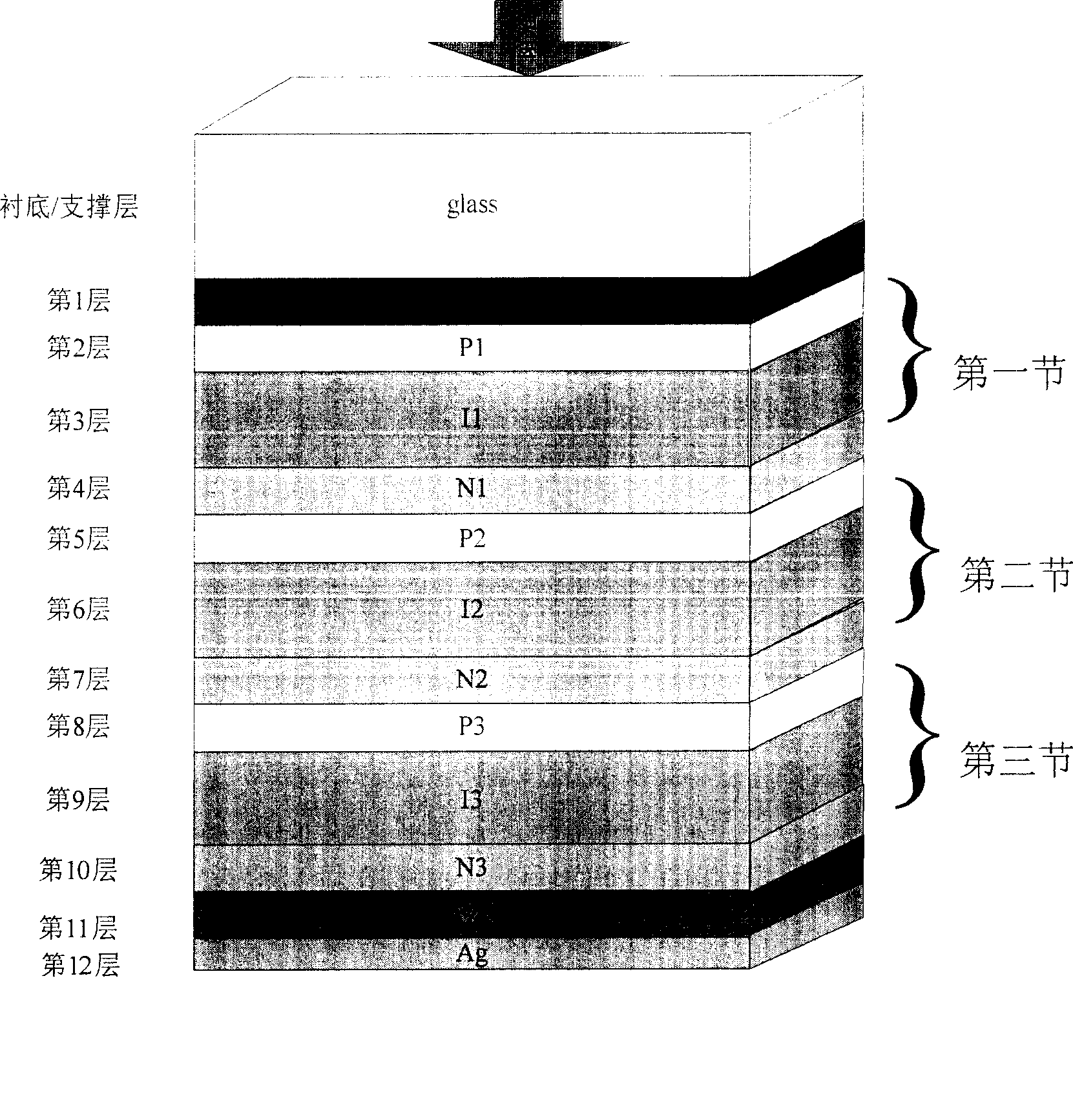

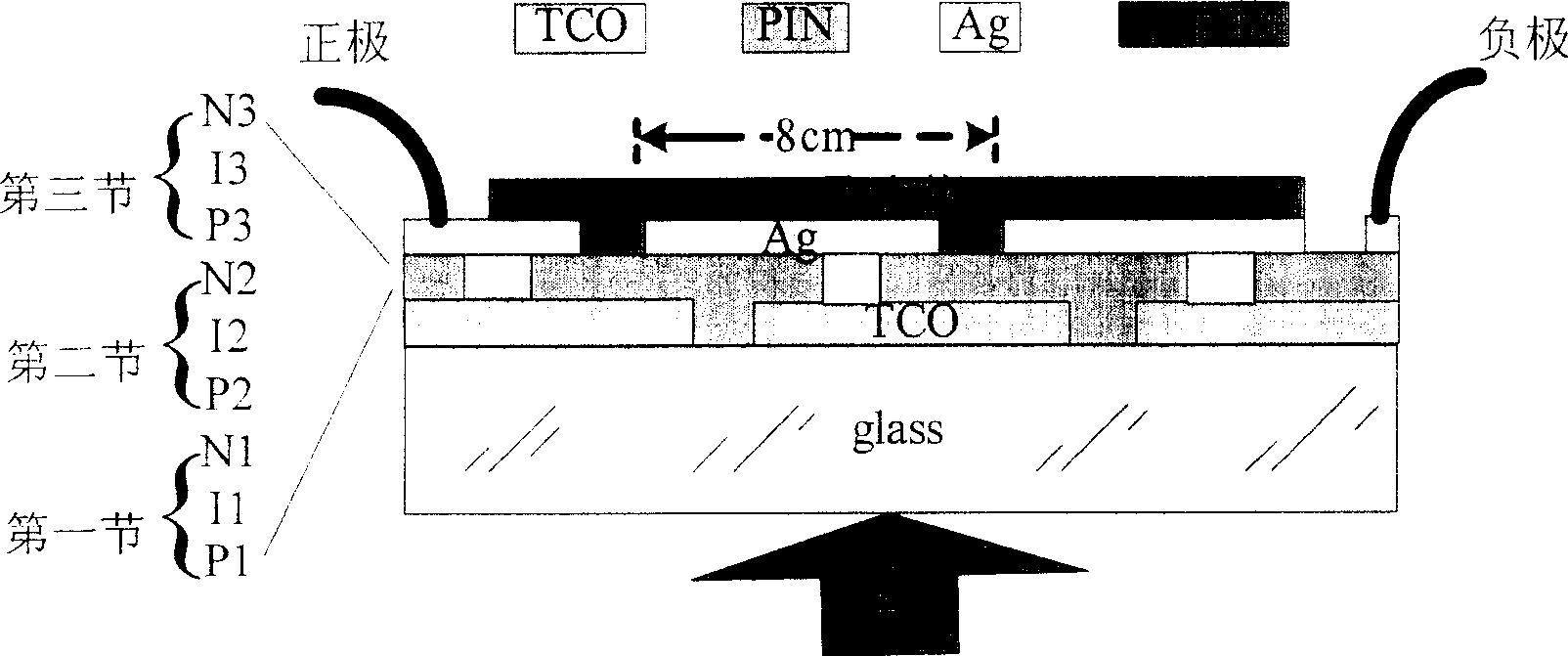

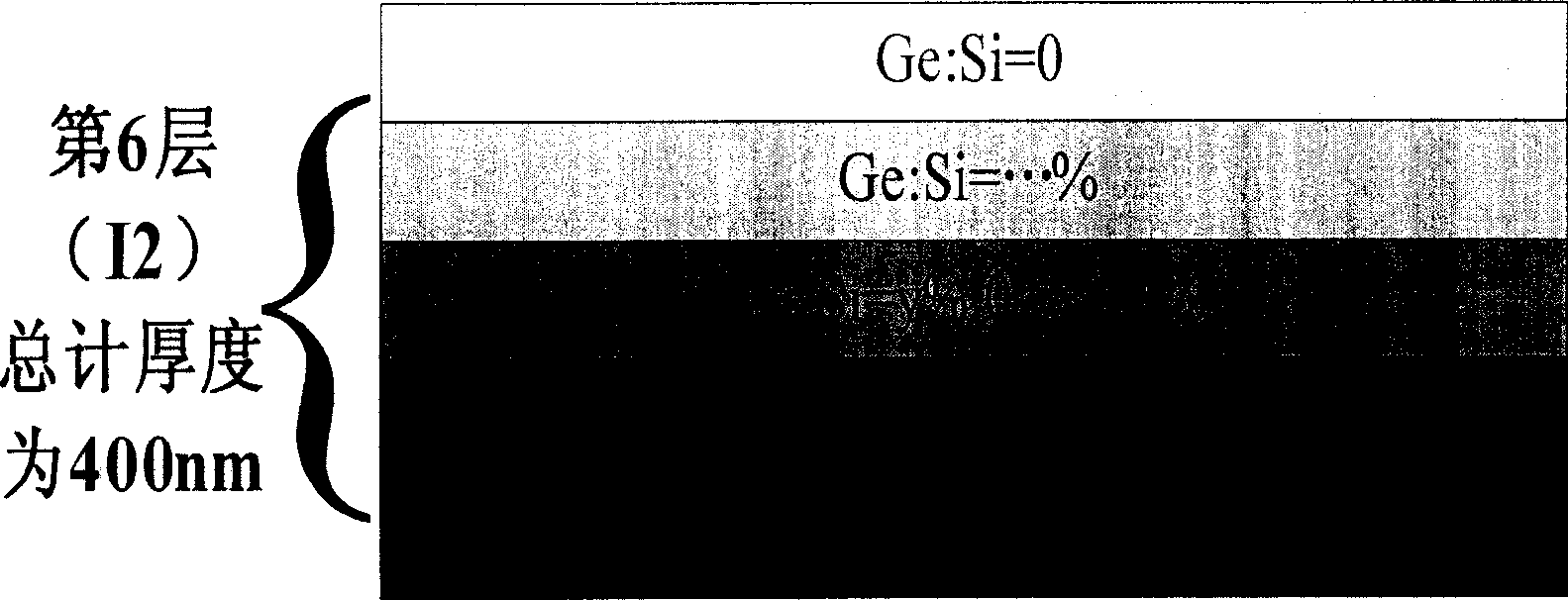

[0038] Such as figure 1 As shown, the thickness of the multilayer film of the thin film battery except the glass part is 2.1 μm. The structure is glass / TCO(200nm) / P1I1N1 / P2I2N2 / P3I3N3 / AZO(200nm) / Ag(100nm). Indium tin oxide ITO is used as a transparent film, which has conductive characteristics and can be used as an electrode of a battery. The first cell adopts p-α-SiC(100nm) / i-α-SiC(300nm) / n-α-SiC(100nm) structure, and the intermediate cell (second cell) adopts p-α-GeSi(100nm) / i-α-Ge x Si 1-x (400nm) / n-α-GeS (100nm) structure, the bottom cell (section 3) uses p-α-Si (100nm) / i-μ-Si (300nm) / n-α-Si (100nm). The thickness of AZO used in the negative electrode is 200nm, and that of Ag is 100nm. The absorption layer film is formed by PECVD reaction, and the ITO and Ag films are formed by sputtering. The glass used has a matte TCO. Deionized water is used for cleaning, megasonic cleaning is used, and laser etching and scribing are used to form a series connection of batteries...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Band gap width | aaaaa | aaaaa |

| Band gap width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com