Biodegradable skull repairing body

A biodegradable and prosthetic technology, applied in the field of biodegradable magnesium alloy prostheses and bone screws, can solve the problem of lack of rights protection, and achieve the effects of good practicability, brain tissue protection, and good bone tissue inducing growth characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

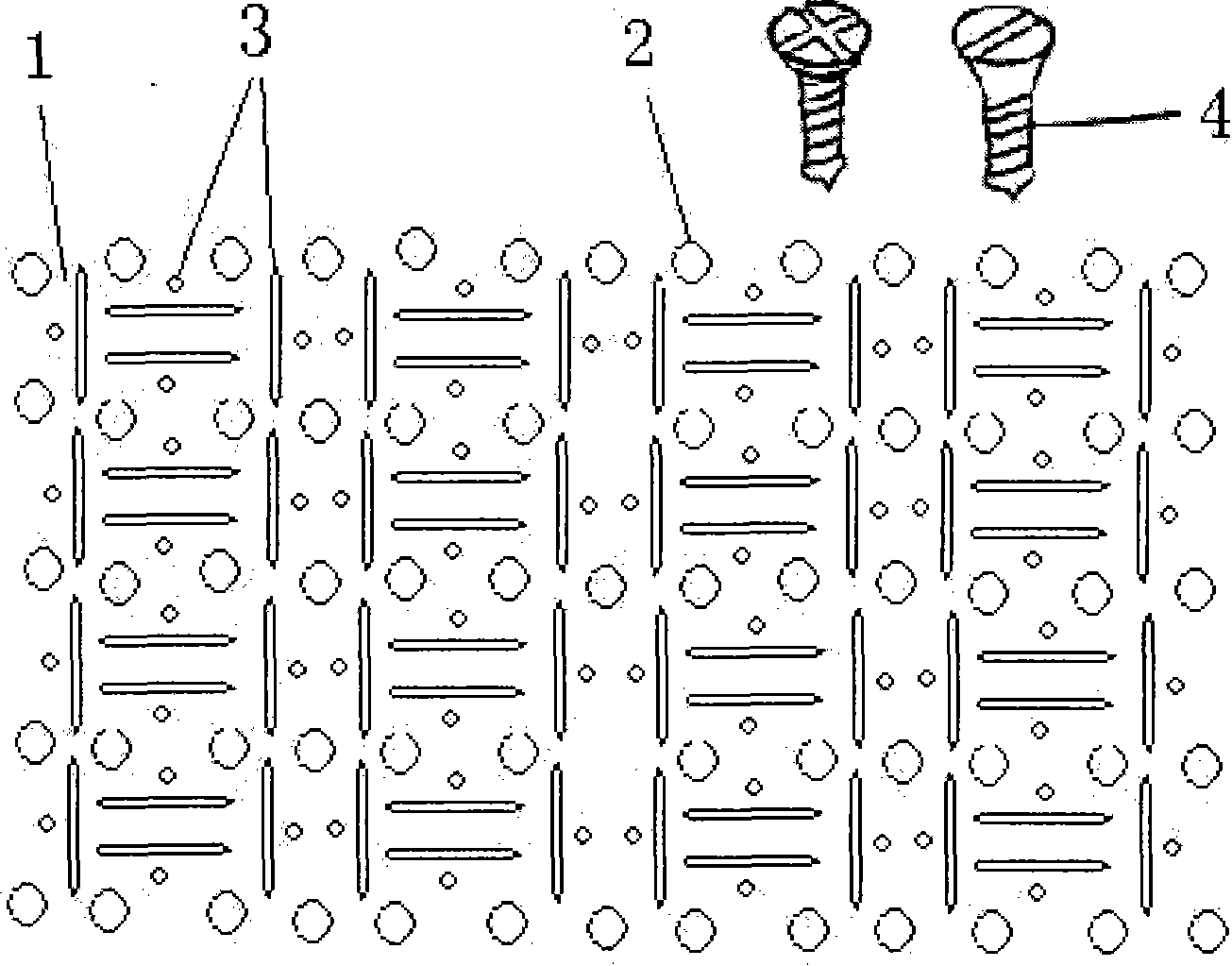

[0029] A degradable prosthesis is made of 0.2mm thick AZ31B alloy sheet, such as figure 1 As shown, after the surface is cleaned, the prosthesis is soaked in 5% di-sodium hydrogen phosphate solution for 2 hours, and a layer of phosphate is formed on the surface through a chemical reaction to improve its surface properties.

Embodiment 2

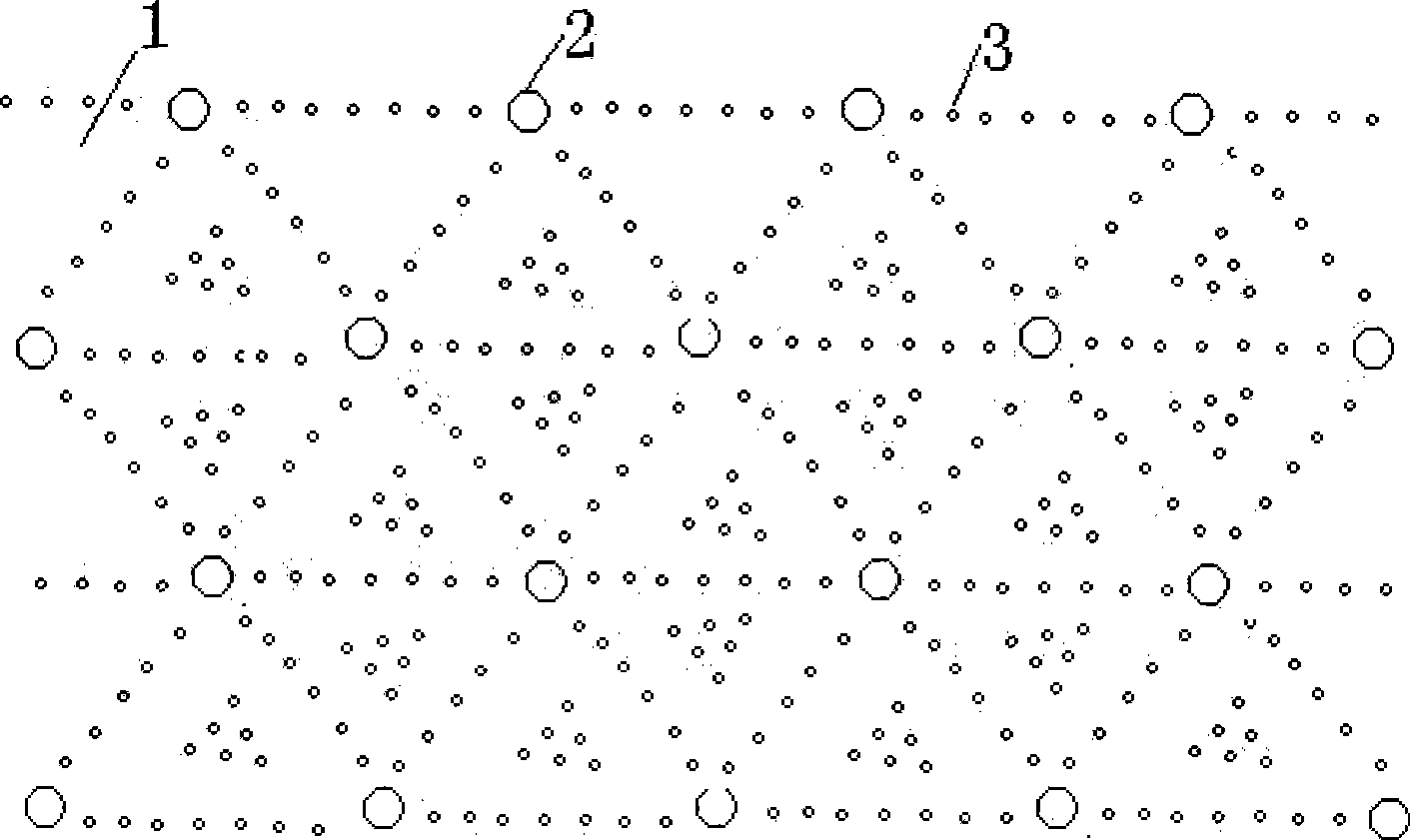

[0031] The 0.08mm thick ZK60 magnesium alloy sheet is processed into a degradable prosthesis, such as figure 2 As shown, after the surface was cleaned, the prosthesis was soaked in a neutral calcium-rich phosphate solution for 3 hours to form a bone-like phosphate layer on the surface and improve tissue compatibility.

Embodiment 3

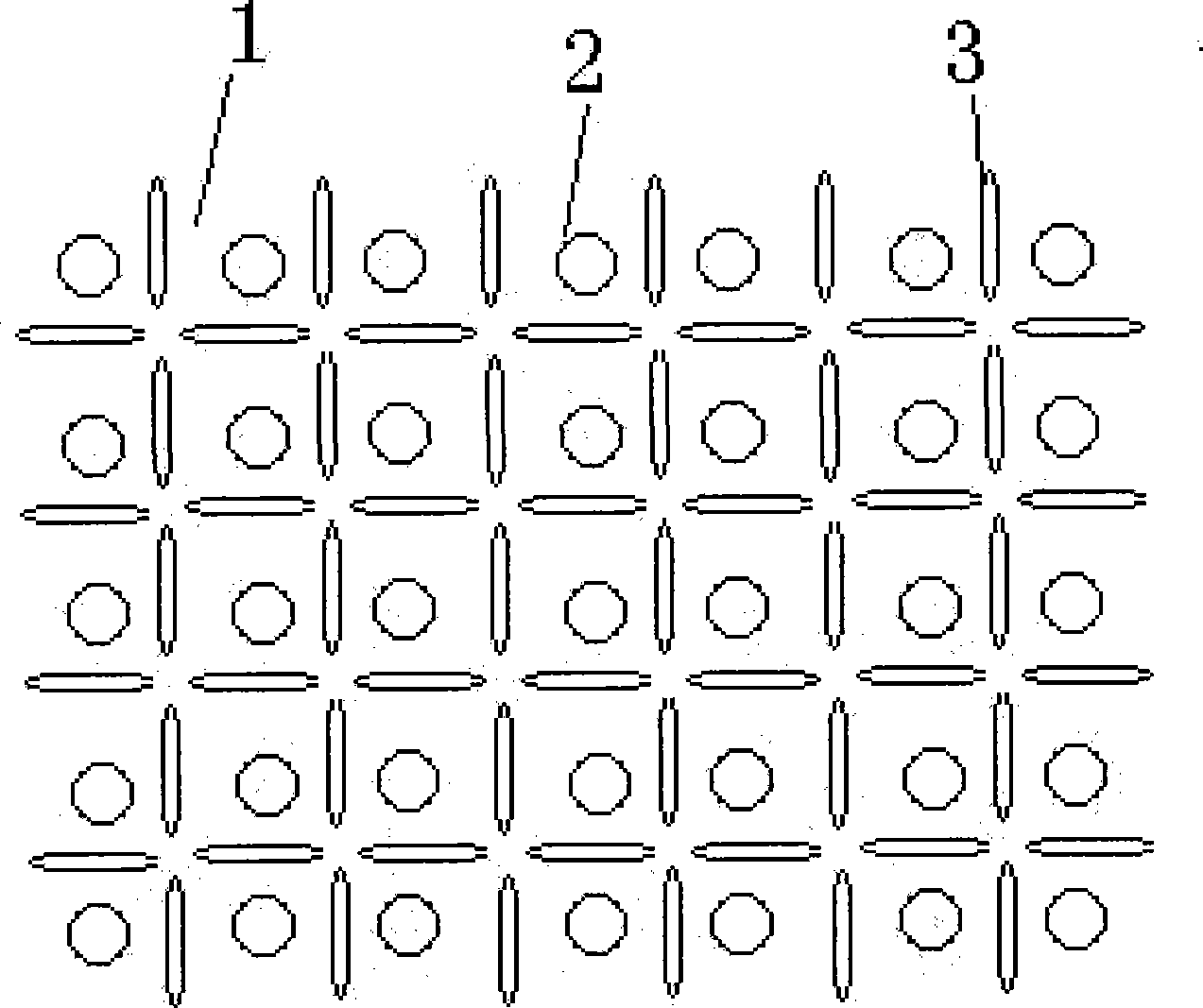

[0033] A 0.1mm thick AZ21 magnesium alloy sheet is made into a degradable prosthesis, such as image 3 As shown, after the surface is cleaned, the surface layer is doped with nitrogen ions and calcium ions by ion implantation. The thickness of the surface layer is about 0.005mm. After the surface is implanted with nitrogen, the surface properties and corrosion degradation speed of the prosthesis can be improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com