Preparation method of photochemical catalyst activated carbon doped titanium dioxide nano material

A photocatalytic activity, nanomaterial technology, applied in the field of inorganic nanophotocatalytic materials, can solve the problems of complex process, increase product production cost, unfavorable large-scale preparation, etc., to simplify production process, reduce production cost, and improve light quantum efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

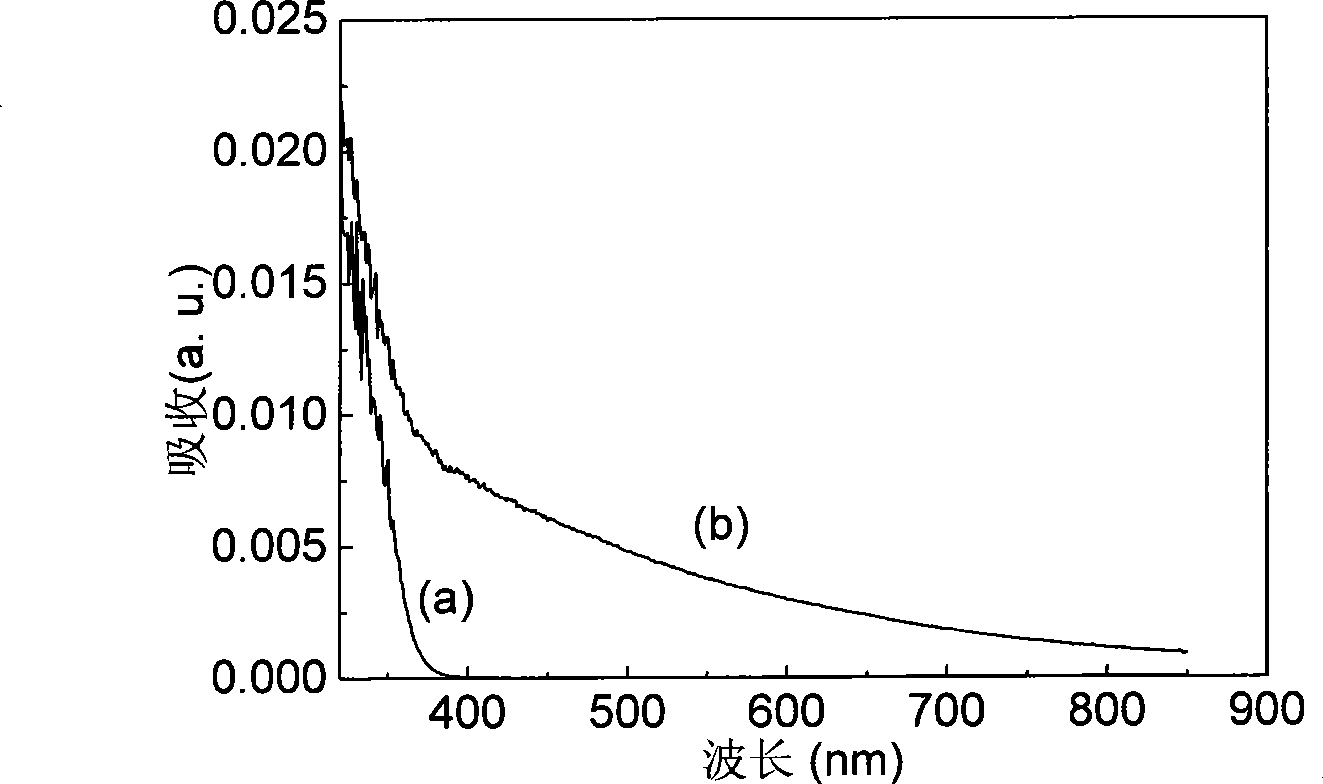

[0024] Take 10ml of tetrabutyl titanate and add it dropwise into 10ml of water, then fully stir and mix for 30min to obtain a white precipitate. The above white precipitated substance was dried at 60° C. for 12 hours, and then ground to obtain a solid powder. The solid powder was heat-treated in an oxygen-deficient device, and calcined in an air atmosphere at 400° C. for 1 hour to obtain a gray-black powder. After the product is collected, it is washed with water and alcohol for 5 times by centrifugation, and then air-dried at 60° C. to obtain carbon-doped titanium dioxide nanopowder with stable performance. The ultraviolet-visible diffuse reflectance absorption spectrum of the prepared carbon-doped titanium dioxide nanopowder is as follows: figure 1shown. The performance test results of degrading methyl orange showed that the decolorization rate of methyl orange reached 92% under visible light for 120 minutes.

Embodiment 2

[0026] Take 10ml of tetraisopropyl titanate and add it dropwise into 20ml of water, then stir and mix thoroughly for 30min to obtain a white precipitate. The above white precipitated substance was dried at 80° C. for 24 hours, followed by grinding to obtain a solid powder. The solid powder was heat-treated in an oxygen deficient apparatus, and calcined in an air atmosphere at 300° C. for 1 hour to obtain an off-white powder. After the product is collected, it is washed with water and alcohol three times by centrifugation, and then air-dried at 60°C to obtain carbon-doped titanium dioxide nanopowder with stable performance. The performance test results of degrading methyl orange showed that the decolorization rate of methyl orange reached 86% under visible light for 120 minutes.

Embodiment 3

[0028] Take 10ml of tetrabutyl titanate and add it dropwise to 5ml of water, then stir and mix thoroughly for 30min to obtain a white precipitate. The above white precipitated substance was dried at 80° C. for 12 hours, followed by grinding to obtain a solid powder. The solid powder was heat-treated in an oxygen-deficient device, and calcined in an air atmosphere at 450° C. for 1 hour to obtain a white powder. After the product was collected, it was washed with water and alcohol three times by centrifugation, and then air-dried at 60° C. to obtain carbon-doped titanium dioxide nanopowder. The performance test results of degrading methyl orange showed that the decolorization rate of methyl orange reached 79% under visible light for 120 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com