Water pump-driving baffling internal circulation bioreactor and use method thereof

A bioreactor, driven technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of secondary pollution, high energy consumption, large amount of sludge, etc. Ease of operation and the effect of reducing the amount of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

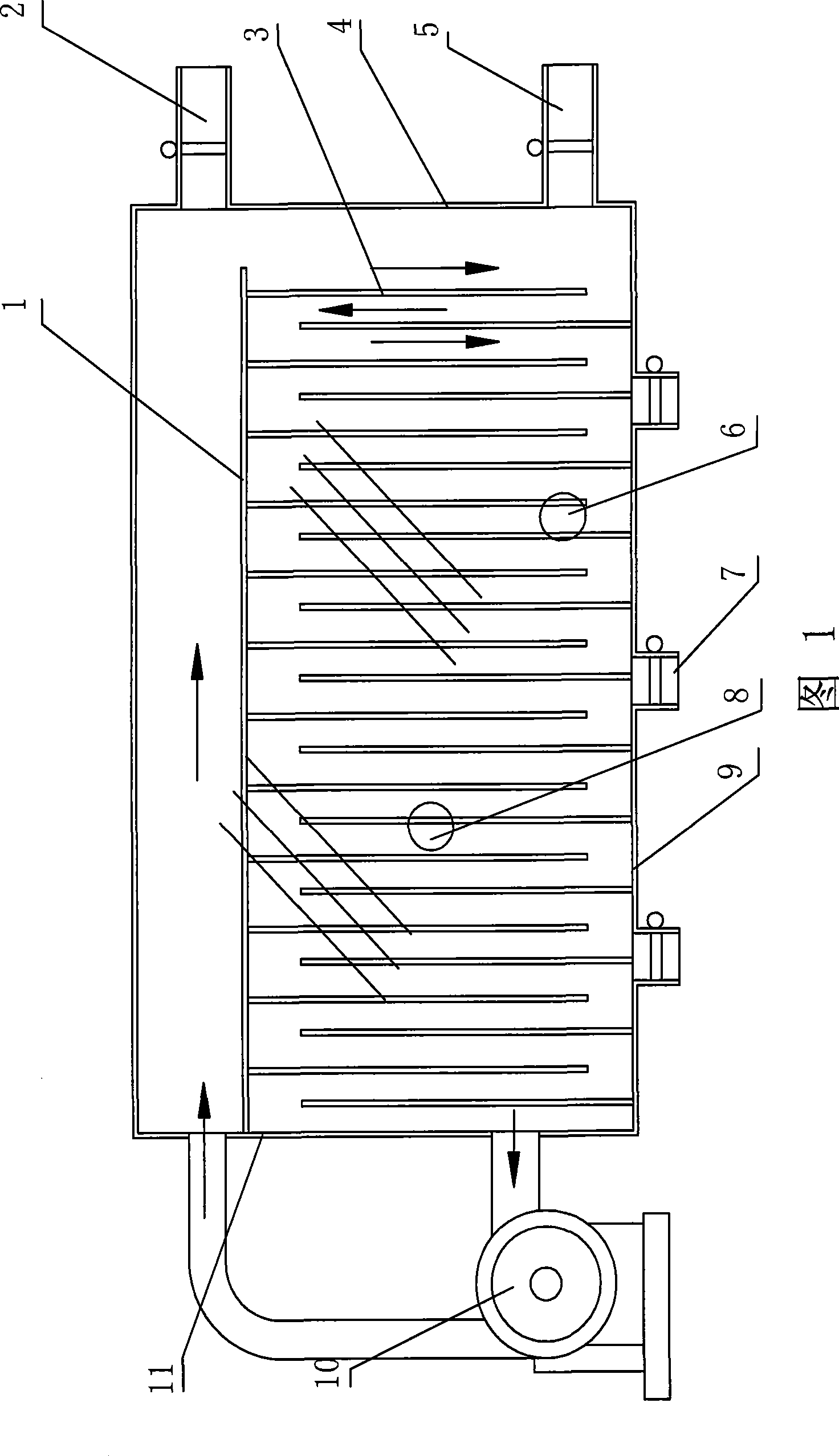

Image

Examples

Embodiment 1

[0045] A baffle type internal circulation bioreactor driven by a water pump 10 is used to continuously treat certain industrial waste water. The concentration of ammonia nitrogen in the wastewater is 20-25mg·L -1 , the total nitrogen concentration is about 35mg·L -1 , NaCl concentration is 3000~8000mg·L -1 scope. The wastewater is substantially free of bioavailable organic carbon sources. Before the treatment, first take the activated sludge for acclimatization and cultivation, and then inoculate the sludge containing halophilic microorganisms into the reactor, and a highly active biofilm will be formed on the baffle within 24 hours. During treatment, glucose solution or methanol is fed in proportion from the feeding port 6 as an additional organic carbon source to treat high-salt wastewater. The reactor can make the removal efficiency of ammonia nitrogen reach more than 99% and the removal rate of total nitrogen reach more than 75% within the residence time of 3 hours.

Embodiment 2

[0047] Bioremediation of urban river water using a pump-driven baffled internal circulation bioreactor. The concentration of ammonia nitrogen in river water is 5-20mg·L -1 , the total nitrogen concentration is 10~35mg·L -1 , the river water is pumped into the reactor, and the intermittent operation mode is adopted, and the water in the reactor is replaced 1 to 2 times a day. After about 5 days of operation, a biofilm with good activity can be formed. Then start continuous operation. During the continuous operation, control the water flow rate so that the hydraulic retention time is 1 to 5 hours. The removal rate of ammonia nitrogen in water reaches more than 99%, and the removal rate of total nitrogen reaches more than 85%.

Embodiment 3

[0049]A pump-driven baffle internal circulation bioreactor is used for continuous advanced treatment of effluent from urban sewage treatment plants. The effluent treated by the urban sewage treatment plant has an ammonia nitrogen concentration of 10-15 mg·L -1 , the total nitrogen concentration is 20~30mg·L -1 , the total phosphorus concentration is 0.5~1.0mg·L -1 , the effluent is continuously input into the reactor, and the influent flow rate is controlled so that the hydraulic retention time is 1 to 2 hours. During the operation, the flocculant is continuously fed in proportion, and after the treatment of the reactor, the removal rate of ammonia nitrogen in the water It can reach more than 90%, the removal of total nitrogen can reach more than 80%, and the removal rate of total phosphorus can reach more than 75%. The effluent from the reactor can be reused as reclaimed water after being sterilized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com