Biological treatment method of coal gas waste water and coking waste water

A coking wastewater and biological treatment technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of poor sludge settling, slow sludge growth, and inability to remove o-cresol and other problems, to achieve the effect of improving treatment efficiency, high removal rate, and alleviating the pressure of nitrification load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

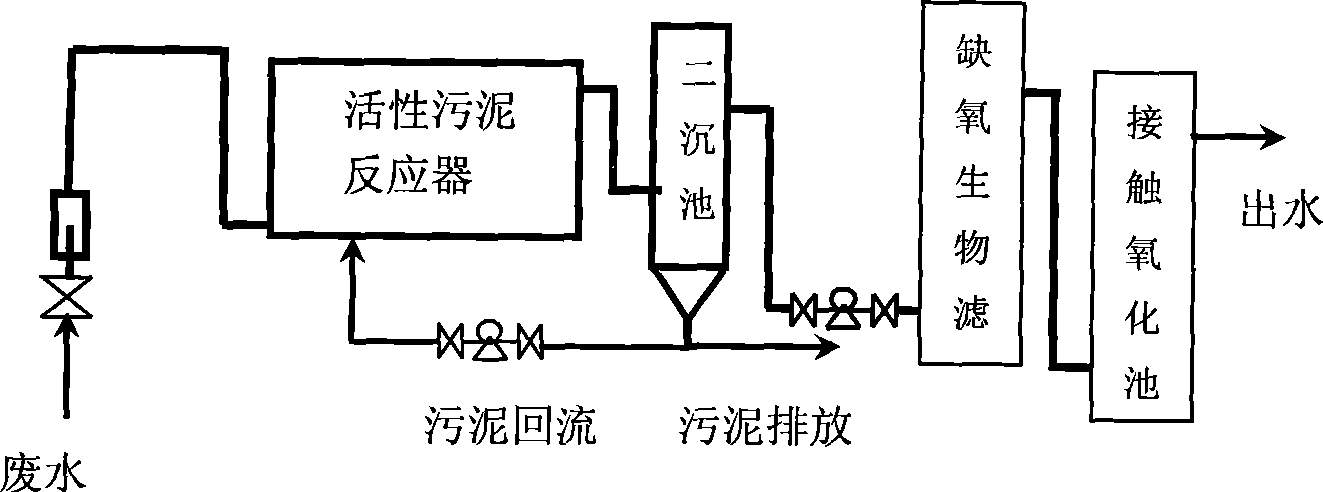

[0028] A gas plant produces an average of 2,000 cubic meters of wastewater per day. The current operating treatment process is: oil removal-dephenol-distillation three-stage activated sludge biological treatment system. Due to the poor pretreatment effect and large fluctuations in water quality, it has a great impact on the subsequent biological treatment system, resulting in poor sludge settling, serious biomass loss, and deterioration of treatment effect. This new process has a better treatment effect on the actual gas wastewater. The combination process of activated sludge method unit, anoxic biological filter unit and biological contact oxidation unit is adopted. The first unit uses activated sludge method, and the second unit uses anoxic biological filter for anoxic treatment. The third unit adopts the biological contact oxidation method to carry out continuous flow operation and treatment of coal gas and coking wastewater. The described activated sludge method is an ordi...

Embodiment 2

[0032] The current wastewater treatment process in a gas plant is the traditional activated sludge method. Due to the change of raw coal, the system treatment effect has deteriorated. Although it has been modified many times, the water output effect is still not good. Adopt aerobic-anoxic-aerobic three unit combination process to process, the first unit activated sludge method of described three unit combination process is the activated sludge method that adds powder material, and its hydraulic retention time is 24 hours, and the solid residence time is 25 days; the subsequent second unit anoxic biological filter is filled with a zeolite carrier with a particle size of 15 mm. After 10 hours, add zeolite or organic carrier to the contact oxidation tank of the third unit, and its hydraulic retention time is 10 hours.

[0033] The dissolved oxygen in the activated sludge system of the first unit and the contact oxidation tank in the third unit of the three-unit combined process i...

Embodiment 3

[0037] The biological treatment method of gas waste water and coking waste water adopted by a certain gas plant adopts aerobic-anoxic-aerobic three-unit combination process for treatment, and the first unit activated sludge process of the three-unit combination process is The activated sludge method with powdered materials, the hydraulic retention time is 20 hours, and the solid retention time is 20 days; the subsequent second unit anoxic biological filter is filled with a zeolite carrier with a particle size of 10 mm, and the temperature in the anoxic section is controlled at 30°C In the aerobic section, the temperature is controlled at 25°C, and its hydraulic retention time is 10 hours. The subsequent third unit contact oxidation tank is filled with zeolite or organic carrier, and its hydraulic retention time is 10 hours.

[0038] The dissolved oxygen in the activated sludge system of the first unit and the contact oxidation tank of the third unit of the three-unit combinatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com