Production technique of immunoglobulin compounding agent capable of preventing and treating poultry respiratory disease

An immunoglobulin and respiratory tract technology, applied to the prevention and treatment of poultry respiratory tract diseases, compound preparations, and the prevention and treatment of animal respiratory tract diseases, can solve problems such as not widely used, and achieve high infection rate, high price, and rapid disease spread. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0052] Raw materials: Chinese herbal medicine extracts such as Yemachai, egg yolk immunoglobulin, carrier

[0053] 1. Preparation of Chinese herbal medicine extracts such as Yemazhui:

[0054] According to the ratio of 10 to 1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1:1, using micro The pulverizer is pulverized and mixed, and then the active ingredients are extracted by ultrasonic waves. The soaking time before extraction is 60-90 minutes. The ultrasonic frequency is 20-40kHz, and the ultrasonic treatment is 30min. After filtration, it is made into powder by low-temperature freeze dryer or spray drying.

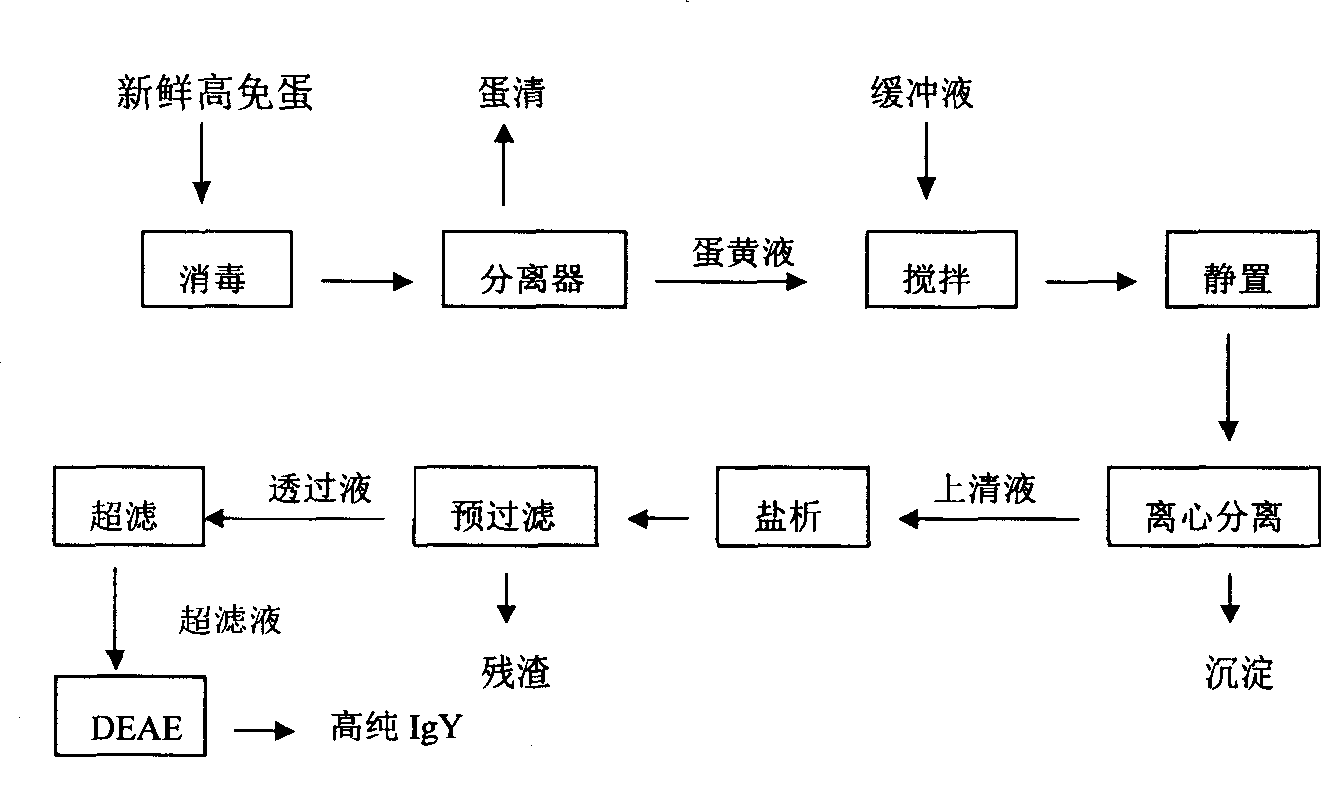

[0055] 2. Preparation of egg yolk immunoglobulin:

[0056] 2.1 Egg immunization preparation: select healthy laying hens, and use commercial or self-made multivalent vaccines for respiratory pathogenic microorganisms (such a...

specific Embodiment approach 2

[0065] Raw materials: extracts of Chinese herbal medicines such as Yemachai, egg yolk, carrier

[0066] 1. Preparation of Chinese herbal medicine extracts such as Yemazhui: according to the Chinese herbal medicines such as Yemazhui, Banlangen, Ephedra, Campanulaceae, Andrographis paniculata, Houttuynia cordata, Astragalus, Tinglizi, Poria 10~1:1:1:1:1:1:1 : Mixed at a ratio of 1:1, pulverized with a micro pulverizer and mixed, and then extracted with ultrasonic waves to extract the active ingredients. The soaking time before extraction is 60-90 minutes. The ultrasonic frequency is 20-40kHz, and the ultrasonic treatment is 30min. After filtration, it is made into powder by low-temperature freeze dryer or spray drying.

[0067] 2. Egg yolk preparation:

[0068] After the fresh high-free eggs are sterilized, beat the eggs manually to get the yolk or get the egg yolk liquid through the egg white / yolk separator.

[0069] 3. Preparation of Chinese herbal medicine and egg yolk com...

specific Embodiment approach 3

[0071] Raw materials: Chinese herbal medicine extract, egg yolk egg white, carrier

[0072] 1.1. Yemazhui and other Chinese herbal medicine extract preparation: according to Yemazhui, Banlangen, Ephedra, Campanulaceae, Andrographis paniculata, Houttuynia cordata, Astragalus, Tinglizi, Poria and other Chinese herbal medicines 10~1:1:1:1:1:1:1 : Mixed at a ratio of 1:1, pulverized by a micro pulverizer and then mixed, and then extracted with ultrasonic waves to extract the active ingredients. The soaking time before extraction is 60-90 minutes. The ultrasonic frequency is 20-40kHz, and the ultrasonic treatment is 30min. After filtration, it is made into powder by low-temperature freeze dryer or spray drying.

[0073] 2. Preparation of egg yolk and egg white:

[0074] After the fresh high-free eggs are sterilized, beat the eggs to get the yolk and egg white, remove the egg shell or get the egg yolk liquid through the egg white / egg yolk separator.

[0075] 3. Preparation of Chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com