White mineral oil for polypropylene

A technology of white mineral oil and polypropylene, applied in the field of white mineral oil, can solve the problems of reduced catalyst activity and easy poisoning, and achieve the effects of reducing catalyst poisoning, uniform particle size and maintaining activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

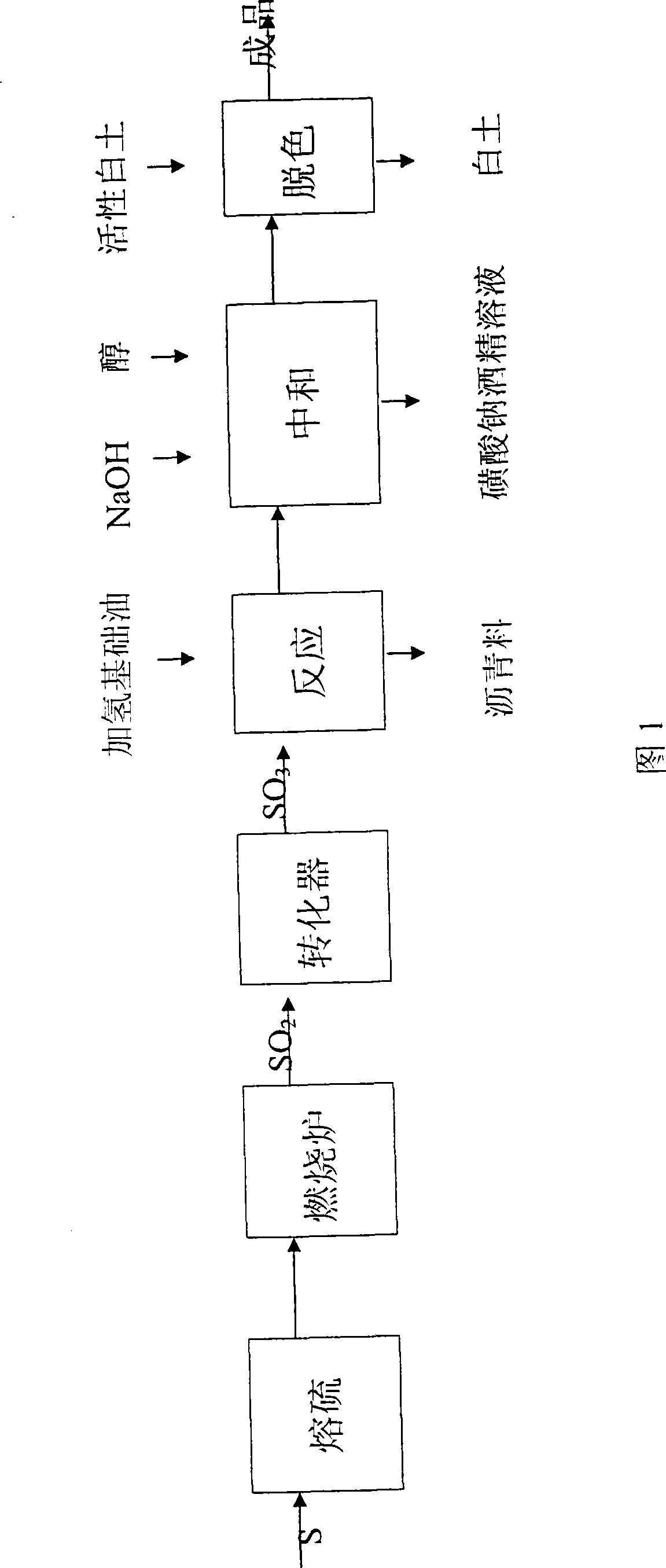

Method used

Image

Examples

Embodiment 1

[0023] The three-stage hydrogenated base oil A (such as Xinjiang naphthenic oil K371) obtained by the three-stage hydrogenation of the 350-550°C fraction section of the fourth reduction line after atmospheric fractionation of crude oil in Karamay Oilfield, Xinjiang;

[0024] Hydrogenated base oil B (300N) obtained by two-stage hydrogenation of the 320-520°C fraction section of the 320-520°C fraction of the 3rd or 4th line after Shanghai Petrochemical's low-sulfur crude oil is fractionated at atmospheric pressure;

[0025] Take 50% of three-stage hydrogenated base oil A and 50% hydrogenated base oil B to form a mixed base oil, and carry out sulfonation treatment on the base oil by sulfur trioxide gas-phase sulfonation method, wherein the gas-phase sulfonation at 55°C for 18 hours, sulfonation The chemical pipeline pressure is 0.04MPa; (the amount of sulfur trioxide is 90 kg / ton);

[0026] Adjust the pH value of the sulfonated hydrogenated base oil to 8 with 40% aqueous sodium h...

Embodiment 2

[0030] Three-stage hydrogenated base oil A (Xinjiang naphthenic oil KNH4010) obtained from three-stage hydrogenation of fractions at 350-550°C in the minus four line after atmospheric fractionation of crude oil from Xinjiang Karamay Oilfield.

[0031] Hydrogenated base oil B (150N) obtained by two-stage hydrogenation of the 320-520°C distillate section of the 320-520°C fraction of the 3rd or 4th line after Shanghai Petrochemical's low-sulfur crude oil is fractionated at atmospheric pressure;

[0032] Take 40% of three-stage hydrogenated base oil A and 60% hydrogenated base oil B to form a mixed base oil, and carry out sulfonation treatment on the base oil by sulfur trioxide gas-phase sulfonation method, wherein, gas-phase sulfonation at 60°C for 15 hours, The pressure of the sulfonation pipeline is 0.025MPa; (the amount of sulfur trioxide is 80 kg / ton);

[0033] Adjust the pH value of the sulfonated hydrogenated base oil to 9 with 20% aqueous sodium hydroxide solution at 65°C;...

Embodiment 3

[0036] After normal-pressure fractionation of crude oil from Karamay Oilfield in Xinjiang, the three-stage hydrogenated base oil A (such as Xinjiang naphthenic oil KP6010) obtained by the three-stage hydrogenation of the 350-550 ° C fraction of the fourth reduction line is obtained.

[0037] Hydrogenated base oil B (300N) obtained by two-stage hydrogenation of the 320-520°C fraction section of the 320-520°C fraction of the 3rd or 4th line after Shanghai Petrochemical's low-sulfur crude oil is fractionated at atmospheric pressure;

[0038] Take three-stage hydrogenated base oil A45%, hydrogenated base oil B55% to form a mixed base oil, and use sulfur trioxide gas-phase sulfonation method to carry out sulfonation treatment on the base oil. The chemical pipeline pressure is 0.06MPa; (the amount of sulfur trioxide is 95 kg / ton);

[0039] Adjust the pH value of the sulfonated hydrogenated base oil to 10 with 30% sodium hydroxide aqueous solution at 70°C;

[0040] Carry out solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com