Polycrystalline-silicon carbide lamination thin-film solar cell

A technology of solar cells and polysilicon layers, applied in the field of solar cells, can solve problems such as low conversion efficiency, achieve reasonable structure, improve utilization rate, and improve photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

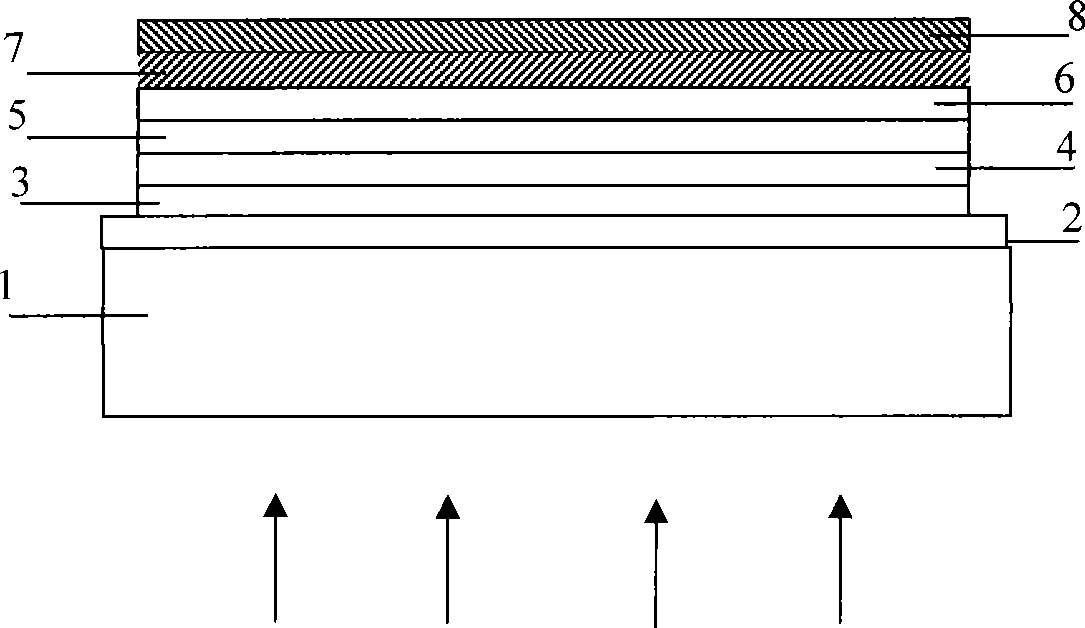

[0031] The first embodiment: preparation of stacked thin film solar cells on glass substrate

[0032] Using ordinary glass as the substrate, after cleaning by standard RCA process, put it into the magnetron sputtering chamber, the background vacuum is better than 5×10 -5 Pa, the vacuum is 0.5Pa during deposition, and the ITO film with a thickness of 600nm is grown by sputtering with an ITO target with a purity of 99.99%. The substrate temperature is 300°C during sputtering, and the visible light transmittance of the grown ITO transparent conductive film is 86%. , the resistivity is about 2×10 -3 Ω·cm.

[0033] Subsequently, the sample was loaded into a hot wire chemical vapor deposition system, and a mixed gas of silane, methane, phosphine and hydrogen was introduced, wherein the ratio of silane to methane was 1:1, and the ratio of phosphine to silane was 1%. The bottom temperature is 400°C, and n-type silicon carbide with a thickness of 50nm is grown; then a mixed gas of si...

no. 2 example

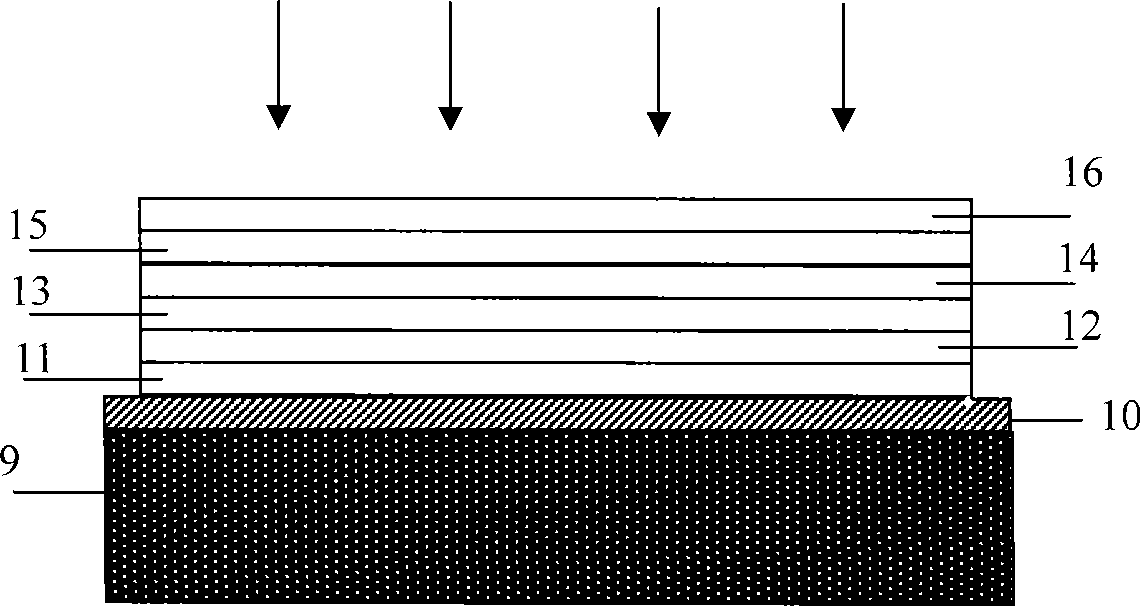

[0035] Second embodiment: preparation of stacked thin film solar cells on stainless steel substrate

[0036] Using stainless steel sheet as the substrate, after cleaning by standard RCA process, put it into the magnetron sputtering chamber, the background vacuum is better than 5×10 -5 Pa, the vacuum is 0.5Pa during deposition, first grow a 400nm Ag reflective layer by sputtering with an Ag target with a purity of 99.99%, and the substrate temperature is room temperature; then grow a layer of 600nm thick Ag with a purity of 99.99% AZO film, the substrate temperature during growth is 450 °C, the visible light transmittance of the grown AZO transparent conductive film is 89%, and the resistivity is about 4×10 -3 Ω·cm.

[0037] Subsequently, the sample was loaded into a hot wire chemical vapor deposition system, and a mixed gas of silane, diborane and hydrogen was introduced, wherein the ratio of diborane to silane was 0.05%, the substrate temperature was 600°C, and the growth th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com