Preparation method for preparing stalk protein feedstuff with microorganism stalk leaven

A technology of straw starter and protein feed, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of low feed intake, reduced straw, and reduced utilization value, and achieves strong applicability and raw material. The effect of wide and short fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation method of microbial straw starter to produce straw protein feed

[0025] The method includes the following steps:

[0026] (a), using yeast, mold, bacillus, lactic acid bacteria, basidiomycete as provenance;

[0027] (b), slant strains: using wort culture medium with a total sugar content of 15%, the inoculum size of the seed solution is 10%, at 30°C, cultured for 26 hours and then stored at a temperature of 4°C;

[0028] (c), test tube liquid strains and first-level liquid culture: use wort medium or starch hydrolysis and saccharification liquid with a total sugar content of 16%, inoculum size is 10%, and culture at 25°C for 30 hours or static culture 30 hours;

[0029] (d), secondary liquid culture: using a starch hydrolysis and saccharification liquid with a sugar content of 15%, and an inoculum size of 10%, at 26°C for 30 hours or static culture for 30 hours;

[0030] (e), liquid culture: using a starch hydrolysis and saccharificatio...

Embodiment 2

[0040] Embodiment 2: the preparation method of microbial straw starter to produce straw protein feed

[0041] The method includes the following steps:

[0042] (a), using yeast, mold, bacillus, lactic acid bacteria, basidiomycete as provenance;

[0043] (b), slant strains: using wort culture medium with a total sugar content of 14%, the inoculum size of the seed solution is 11%, at 26°C, cultured for 28 hours and then stored at a temperature of 4°C;

[0044] (c), test tube liquid strains and first-level liquid culture: use wort medium or starch hydrolysis and saccharification solution with a total sugar content of 18%, inoculum size is 18%, and culture for 40 hours or static culture at 30°C 40 hours;

[0045] (d), secondary liquid culture: using a starch hydrolysis and saccharification liquid with a sugar content of 18%, and an inoculum size of 12%, at 30°C for 38 hours or static culture for 38 hours;

[0046] (e), liquid culture: using a starch hydrolysis and saccharificatio...

Embodiment 3

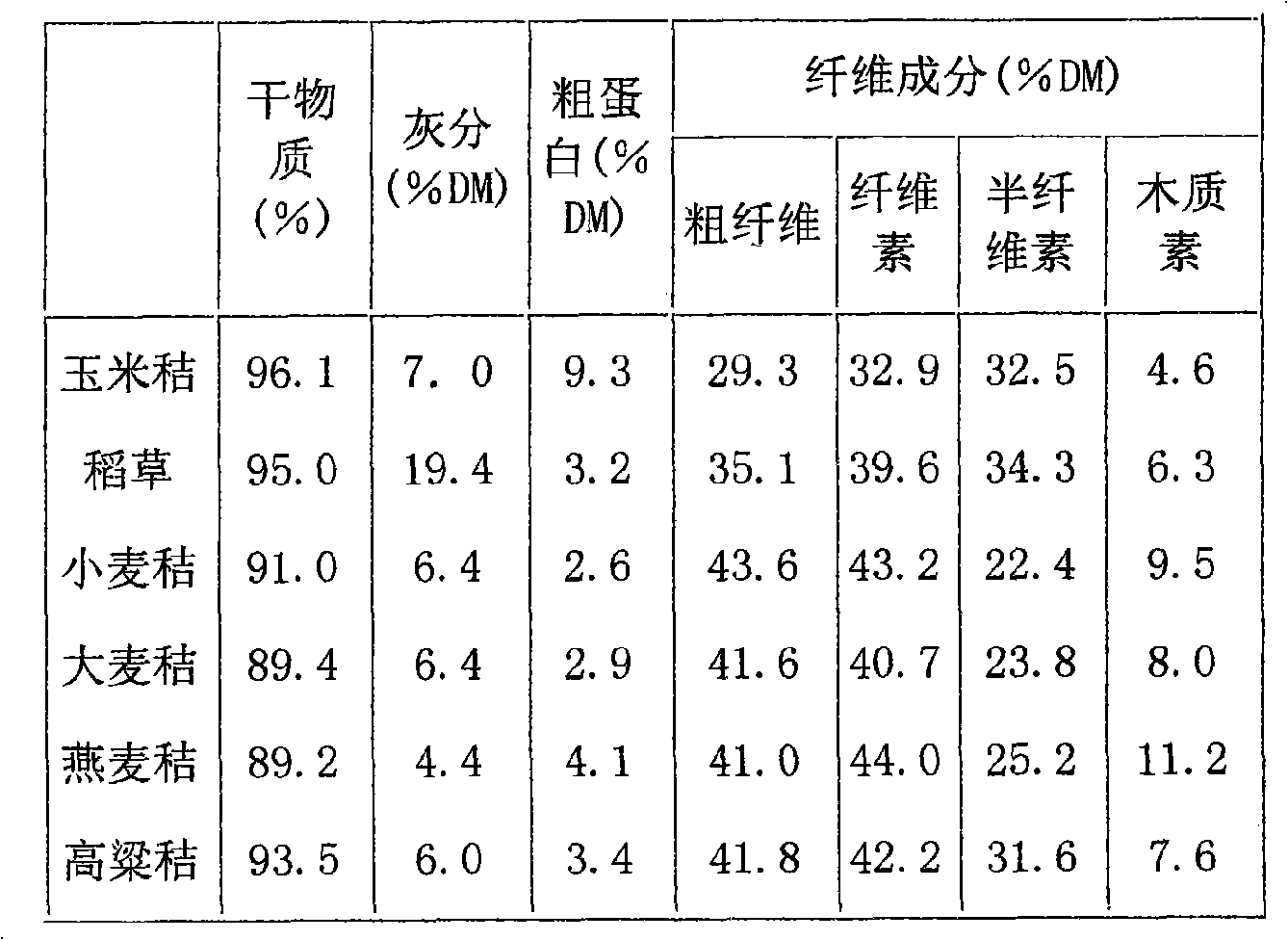

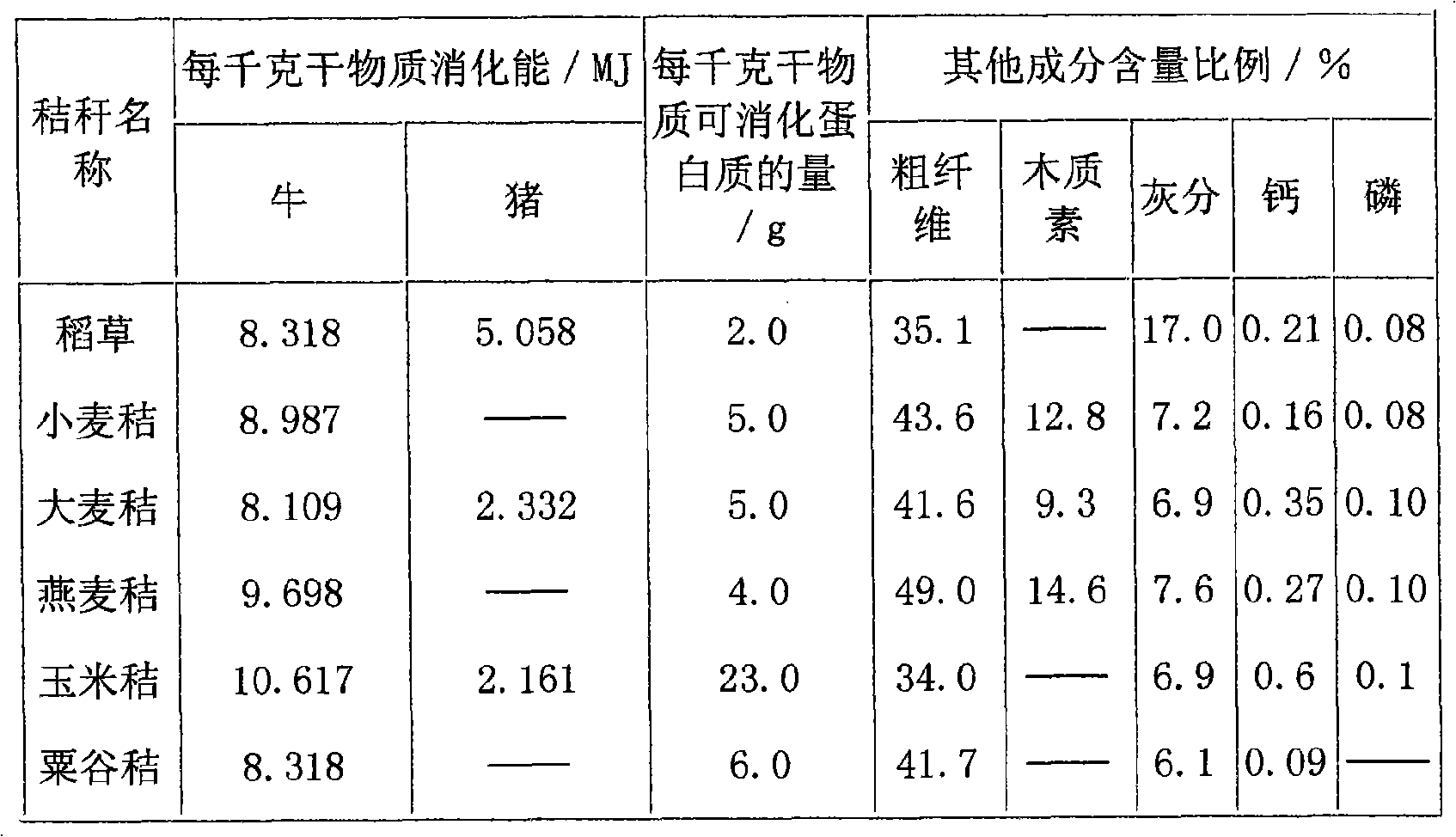

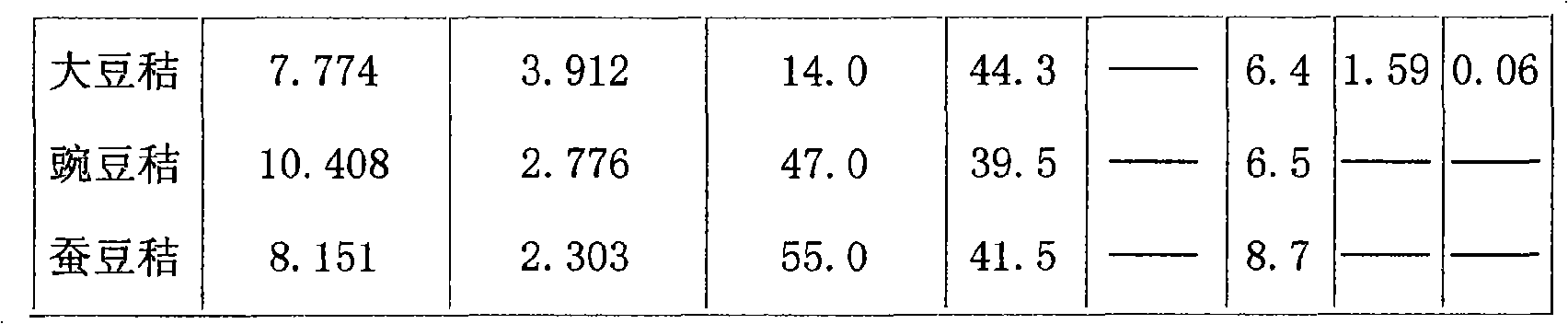

[0056] Example 3: Composition and nutritional value of straw

[0057] 1. Composition and digestibility of straw

[0058] (1) The crude fiber content is very high, and the straw is mostly in the post-mature stage of the plant. At this time, the degree of lignification of the plant cells is very high, generally between 31% and 45%.

[0059] The main component of straw is fiber (Table 1, 2), which is mainly concentrated in cell wall, and the cell wall content accounts for more than 70%, which is composed of cellulose, hemicellulose and lignin; acid detergent fiber is composed of cellulose and lignin. Cellulose and hemicellulose can be hydrolyzed by cellulolytic bacteria in the rumen of cattle and sheep to generate volatile fatty acids, such as acetic acid, propionic acid, butyric acid, etc., which are absorbed by cattle and sheep as energy. Bacteria in the rumen cannot break down lignin. The cellulose, hemicellulose and lignin in the straw are closely combined, which affects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com