Reinforced anti-split agent for materials such as lime and coal ash

A technology to enhance anti-cracking agent and fly ash, which is applied in the field of enhanced anti-cracking agent of lime and fly ash materials, which can solve the problems of shrinkage cracking and low early strength, and achieve obvious strength, reduced construction cost and obvious growth Effect

Inactive Publication Date: 2011-07-20

HUBEI GEZHOUBA TESTING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a reinforced anti-cracking agent for lime and fly ash materials, which can solve the problems of low early strength and shrinkage cracking of lime and fly ash materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] Take 65 parts of silicate mineral powder, 20 parts of gypsum, and 15 parts of potassium sulfate, and mix them evenly.

Embodiment 2

[0024] Take 55 parts of silicate mineral powder, 30 parts of phosphogypsum, and 15 parts of sodium sulfate, and mix them evenly.

Embodiment 3

[0026] Take 55 parts of silicate mineral powder, 30 parts of gypsum, and 15 parts of sodium sulfate, and mix them evenly.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

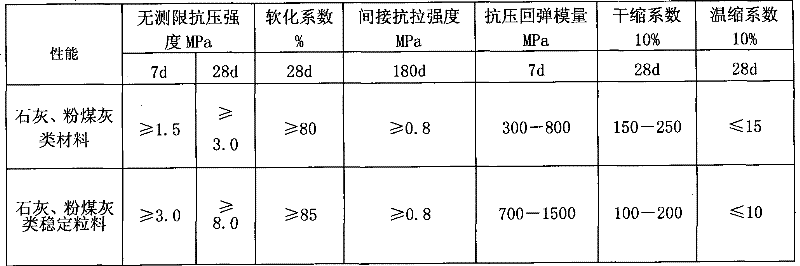

The present invention provides a reinforcing anti-crack agent for lime and fly ash materials, which comprises silicate mineral powder, gypsum or chemical engineering waste residue phosphogypsum and an alkali metal substance containing SO3, wherein the tricalcium silicate content of the silicate mineral powder is more than 55 percent; for the lime and fly ash materials or lime and fly ash aggregates, the early strength is quite low, the anti-crack performance is poorer; after doping the reinforcing anti-crack agent, the early strength of the lime and fly ash materials or the lime and fly ash aggregates is obviously improved, and other performances are also improved, and particularly the anti-crack performance is greatly improved, thereby effectively solving the problem that the road surface is easy to crack; and the industrial waste residue and acetylene residue are used to replace lime, and the poor-quality fly ash replaces the fly ash with second-level or higher level, thereby obviously lowering the construction cost and obtaining good economic benefits.

Description

technical field [0001] The invention relates to a lime and fly ash material used as the subbase and base material improvement of road surfaces of various grades, in particular to an enhanced anti-cracking agent for lime and fly ash materials. Background technique [0002] Lime and fly ash materials are used as the subbase and base course of road pavements of various grades. It has long operating time, high mid-late strength and rigidity, high board performance, high road bearing capacity, and good durability. Low cost, good for environmental protection, etc., but this kind of material has low early strength and large shrinkage, which is easy to cause early cracking of the road surface, resulting in certain influence and restrictions on its use. Contents of the invention [0003] The purpose of the present invention is to provide a kind of reinforced anti-cracking agent of lime and fly ash materials, which can solve the problems of low early strength and shrinkage cracking ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B22/14C04B14/04

Inventor 宋拥军谭恺炎程润喜陈志远曾伟陈军琪

Owner HUBEI GEZHOUBA TESTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com