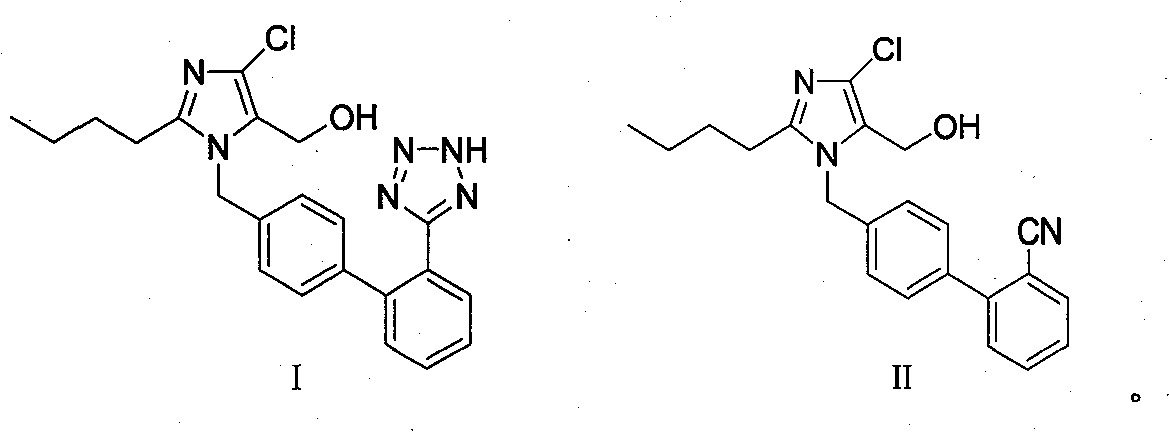

Preparation of losartan

A technology of reaction solution and hydroxymethyl, which is applied in the field of preparation of losartan, a high blood pressure drug, can solve problems such as difficult recovery of solvents, environmental impact, and impact on product yield, and achieve the goals of small amount of solvent, small damage, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

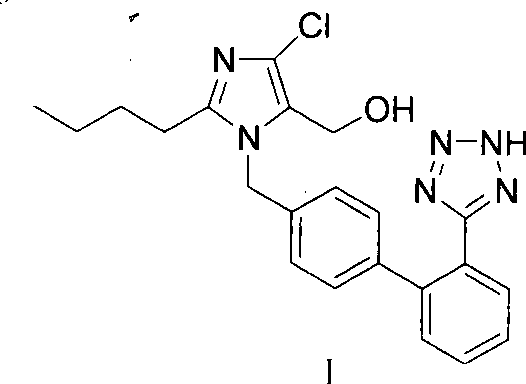

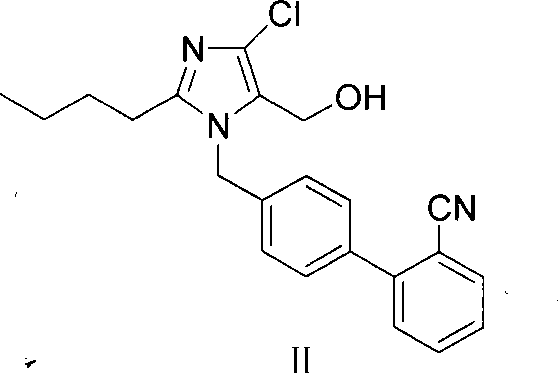

[0028] Example 1: Preparation of Losartan

[0029] To 2-butyl-4-chloro-5-(hydroxymethyl)-1-{[(2'-cyano)biphenyl-4-yl]methyl}imidazole (200g, 0.53mol), azide Add 400ml of toluene to sodium (100g, 1.54mol) and triethylamine hydrochloride (215g, 1.54mol), react at 100°C for 40 hours, cool to 20-30°C, adjust the pH of the reaction solution with alkaline water 9-10, separate the toluene layer, add sodium metabisulfite (50g, 0.26mol) to the resulting reaction solution, stir for 30 minutes, add 200ml ethyl acetate, adjust the pH of the reaction solution to 3.5 with dilute hydrochloric acid, and stir for 6 hours to obtain a solid wet The wet product was dissolved in 400ml isopropanol, heated under reflux and cooled to 10-20°C, filtered and dried to obtain Losartan (201g, molar yield 90%).

Embodiment 2

[0030] Example 2: Preparation of Losartan

[0031] To 2-butyl-4-chloro-5-(hydroxymethyl)-1-{[(2'-cyano)biphenyl-4-yl]methyl}imidazole (200g, 0.53mol), azide Add 400ml of toluene to sodium (100g, 1.54mol) and triethylamine hydrochloride (215g, 1.54mol), react at 100°C for 40 hours, cool to 20-30°C, adjust the pH of the reaction solution with alkaline water 9-10, divided into three layers, add sodium metabisulfite (50g, 0.26mol) to the middle layer, stir for 30 minutes, add 200ml ethyl acetate, adjust the pH of the reaction solution to 3.5 with dilute hydrochloric acid, and stir for 6 hours to obtain a solid wet product. The wet product was dissolved in 400ml of isopropanol, heated under reflux and cooled to 10-20°C, filtered and dried to obtain Losartan (203g, molar yield 91%).

Embodiment 3

[0032] Example 3: Preparation of Losartan

[0033] To 2-butyl-4-chloro-5-(hydroxymethyl)-1-{[(2'-cyano)biphenyl-4-yl]methyl}imidazole (200g, 0.53mol), azide Add 400ml of toluene to sodium (100g, 1.54mol), triethylamine hydrochloride (215g, 1.54mol), react at 120°C for 40 hours, cool to 20-30°C, adjust the pH of the reaction solution to 9 with alkaline water ~10, separate the toluene layer, add sodium nitrite (36.6g, 0.53mol) to the resulting reaction solution, stir for 30 minutes, add 200ml ethyl acetate, adjust the pH of the reaction solution to 3.0 with dilute hydrochloric acid, stir for 8 hours, filter and dry Losartan (215 g, 96% molar yield) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com