Process for producing protopine total alkaloids extract

A technology for total alkaloids and extracts, which is applied in the field of preparation of total alkaloids extracts of Pitto, can solve the problems such as the industrialized production method of high-purity Pttocate total alkaloids has not been found, and meets the requirements of circular economy, The effect of improving the utilization rate and having a good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

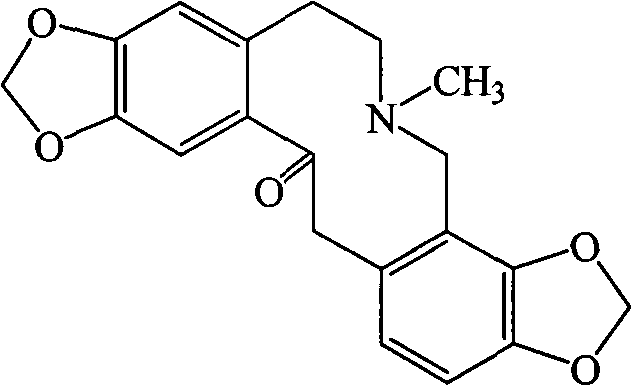

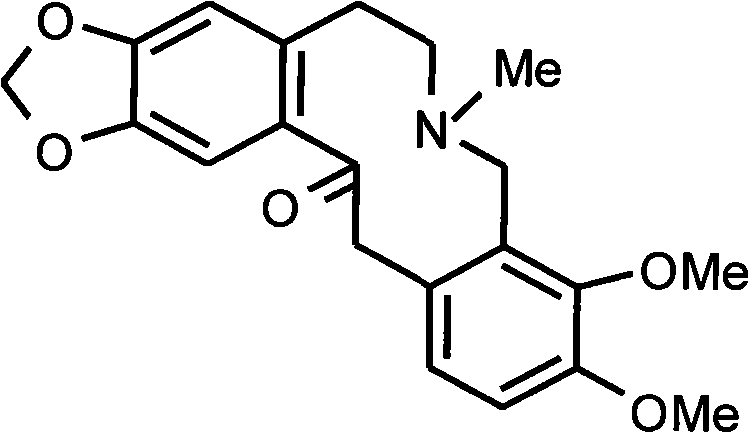

Image

Examples

Embodiment 1

[0047] Boluohui fruit pods 2kg, dried at 55°C, crushed, with 10 times the amount of 1% H 2 SO 4 The aqueous solution was extracted twice at 80°C, each time for 1 hour, adjusted to pH 9 with 10% NaOH aqueous solution, filtered, and the supernatant liquid was released directly, and the suspension in the lower layer was filtered to obtain the filtrate and precipitate b (as the production of total triphenylene The crude total alkali raw material), supernatant and filtrate are merged into filtrate a (when producing total benzophenanthridine alkaloids, generally discarded as waste water); (1) get filtrate a and absorb through macroporous resin, Then use ethanol gradient elution, collect 80% ethanol eluate, evaporate to dryness under reduced pressure, dry at room temperature, eluate is dissolved in ethyl acetate, crystallizes to obtain protoline alkaloid I; (2) precipitate b with 90% industrial Ethanol 10 times the amount of reflux extraction twice, each time for 1 hour, the extract...

Embodiment 2

[0049] Boluohuigen 3kg, dried at 55°C, pulverized, with 10 times the amount of 1% H 2 SO 4 Extract the aqueous solution at 80°C for 2 times, each time for 1 hour, adjust the pH to 9 with 10% NaOH aqueous solution, filter, release the supernatant directly, filter the suspension in the lower layer to obtain the filtrate and precipitate b, and the supernatant and filtrate are the filter residue Solution a; (1) Take the filtrate residue a and absorb it with a macroporous resin, then elute with ethanol gradient, collect the 80% ethanol eluate, evaporate to dryness under reduced pressure, and dry at room temperature, and the eluate is dissolved and crystallized by dichloromethane Obtain the total alkaloid I; (2) Precipitate b was refluxed twice with 90% industrial ethanol for 1 hour, and the extract was extracted with 10% H 2 SO 4 Adjust the pH of the aqueous solution to 1-2, filter, add alkali to the filtrate until it is neutral, concentrate until it has no alcohol smell, and it ...

Embodiment 3

[0051] 5 kg of stems and leaves of Boluohui, dried at 55°C, crushed, extracted twice with 10 times the amount of 2% HCl aqueous solution at 80°C, 1 hour each time, adjusted to pH 9 with 10% NaOH aqueous solution, filtered, and released the upper layer directly Clear liquid, filter the suspension in the lower layer to obtain filtrate and precipitate b, the supernatant and filtrate are filtrate a; (1) take filtrate a and absorb it with macroporous resin, then elute with ethanol gradient, and collect 80% The ethanol eluate was evaporated to dryness under reduced pressure and dried at room temperature, and the eluate was dissolved in ethanol and crystallized to obtain the total alkaloid I; (2) the precipitate b was reflux extracted twice with 10 times of 90% industrial ethanol, each time for 1 hour, Adjust the pH of the extract to 1-2 with 2% HCl aqueous solution, filter, add alkali to the filtrate until it is neutral, concentrate until it has no alcohol smell, and leave to cool to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com