Integrated method for cyclic utilization with microorganism biomass in production process of 2,3-butanediol

A butanediol and product technology, applied in the field of microbiology, can solve the problems of waste bacteria environment, waste of resources and energy, loss of carbon and nitrogen sources and other biomass resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Embodiment 1. the cultivation of Serratia marcescens

[0068] Said Serratia marcescens (Serratia marcescens) is provided by China Industrial Microorganism Culture Collection Management Center, and the number is Serratia marcescens CICC10187.

[0069] (1) Seed cultivation

[0070] The seeds preserved in glycerol tubes were cultured on a shaker for 24 hours, with one transfer every 12 hours, and the culture temperature was 30° C., 190 r / min.

[0071] The components and contents of the culture medium are (content per liter): glucose 10g; yeast powder 1g; peptone 2g; (NH 4 ) 2 SO 4 6g;K 2 HPO4 10g; NaCl 0.5g; MgSO 4 0.5g; after sterilization, adjust the pH to 6.6 with NaOH solution before inoculation. The balance is water.

[0072] (2) Fermentation culture

[0073] 3.7L bioreactor culture: the seed liquid is inserted in the fermentation medium with the inoculation amount of 5% (volume ratio) and cultivated, and the fermentation medium is (content in every liter):...

Embodiment 2

[0078] Example 2. Feasibility Analysis of Thalline Recovery and Utilization and Optimization of Adding the Amount of Fermentation Recovery Thalline

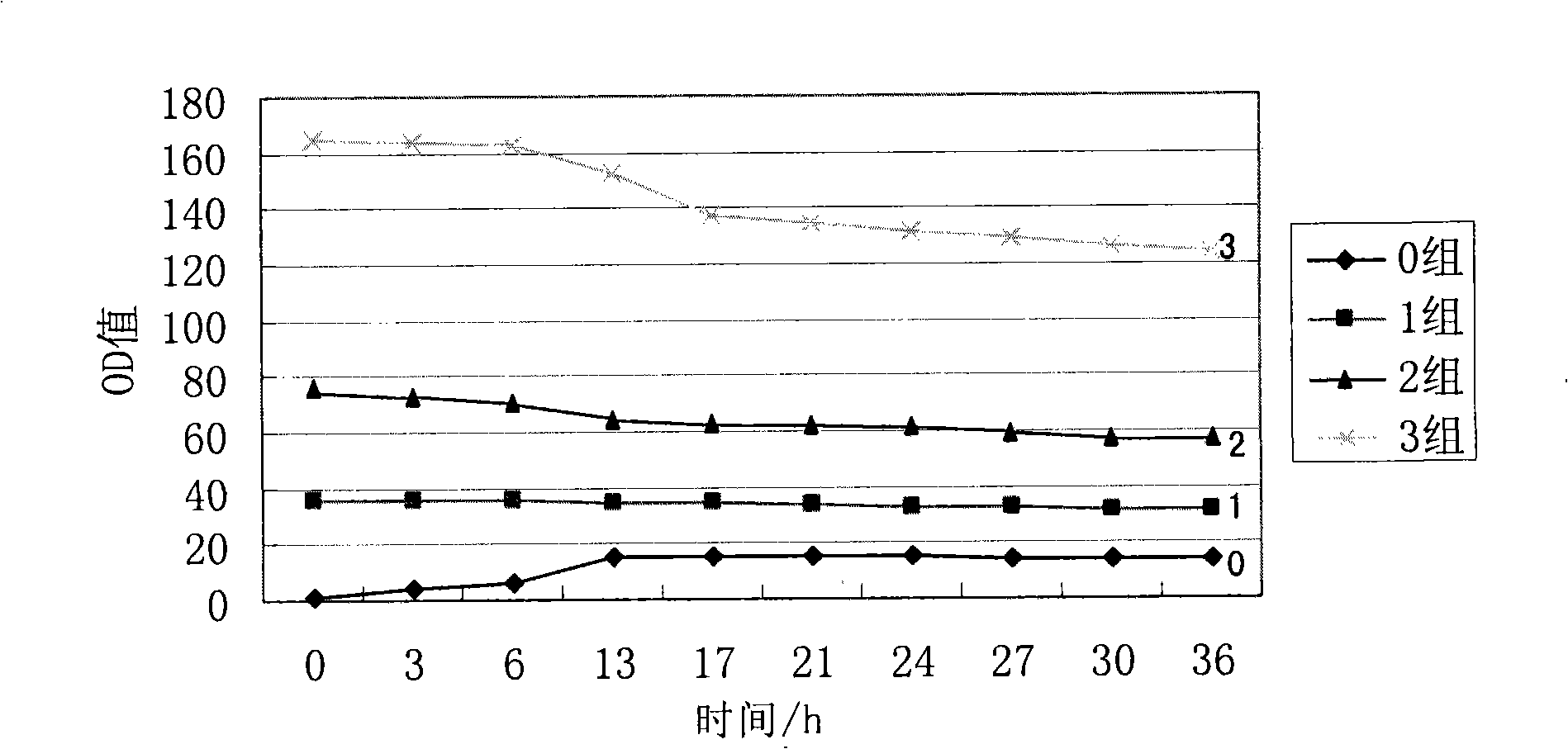

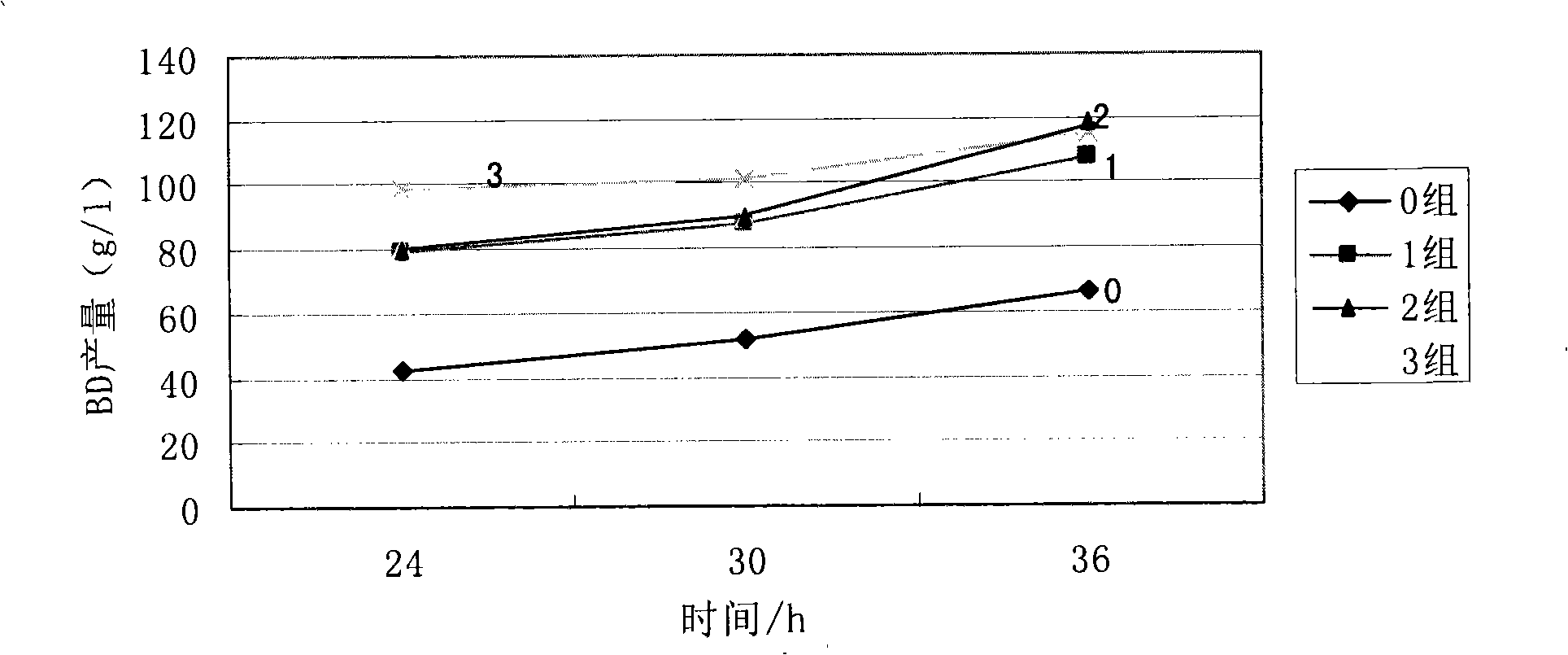

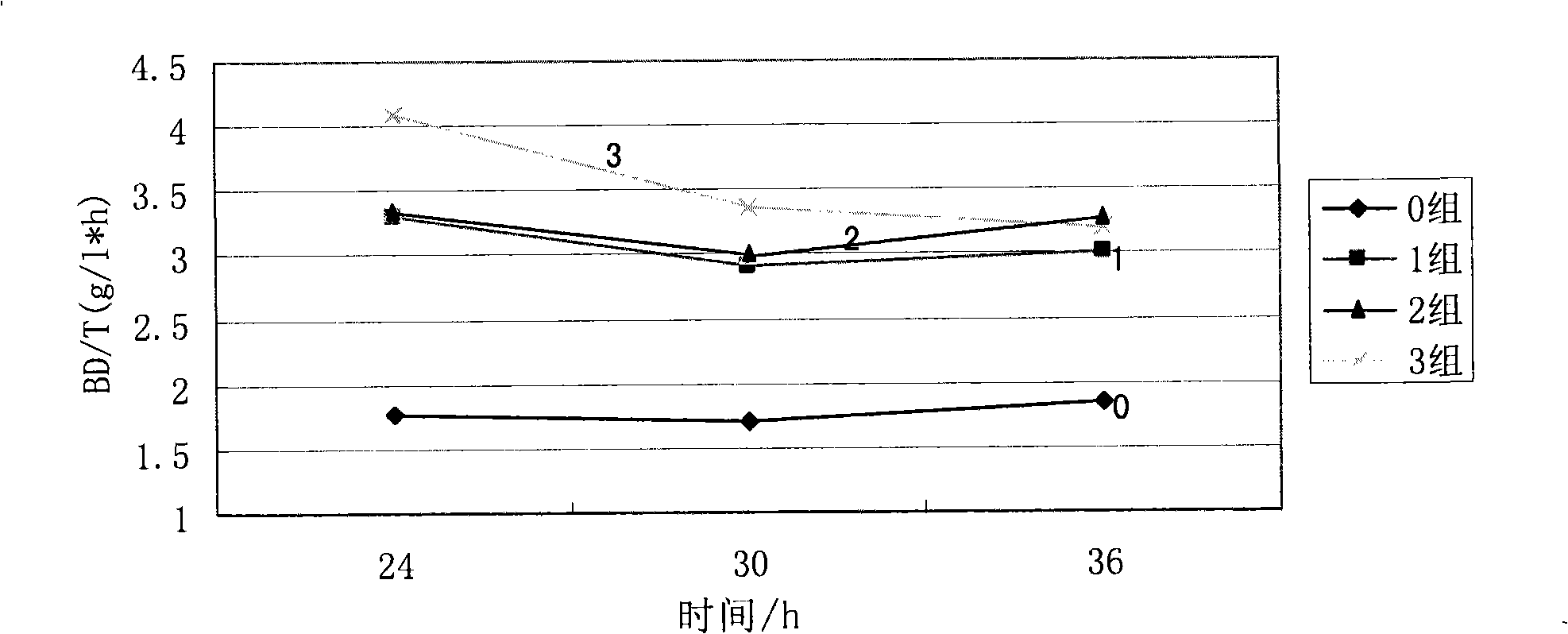

[0079] By fermentation experiment, insert the living thalline (being reclaimed thalline) of the fermentation end stage that inserts 3.7L bioreactor culture in the blank fermented liquid, insert different amounts of reclaimed thalline in the research fermentation process, and compare with control group ( Whether there are significant differences in the yield (g / l), sucrose utilization (g / g) and product yield (g / l*h) of the fermentation product (g / l) without adding the recovered cells), and examine whether the addition of different cells The impact of volume on each indicator.

[0080] Experimental Materials:

[0081] (1) Seed medium (content per liter): glucose 10g, yeast powder 1g, peptone 2g, (NH 4 ) 2 SO 4 6g, KH 2 PO 4 10g, NaCl 0.5g, MgSO 4 0.5g. The balance is water.

[0082] (2) Shake flask fermentation medium (...

Embodiment 3

[0103] Embodiment 3. Recover the comparison of thalline adding opportunity

[0104] Through the shaking table experiment, the fermented liquid was inserted into live bacteria in different fermentation stages, and the output (g / l) of the fermentation product, the utilization rate of sucrose (g / g), and the productive rate of the product (g / l) were compared between each group. *h) Whether there is a significant difference, and determine the best time to inoculate live bacteria among several groups.

[0105] Experimental Materials:

[0106] (1) Seed medium (content per liter): glucose 10g, yeast powder 1g, peptone 2g, (NH 4 ) 2 SO 4 6g, KH 2 PO 4 10g, NaCl 0.5g, MgSO 4 0.5g. The balance is water.

[0107] (2) Shake flask fermentation medium (content per liter): 90g sucrose, 20g peptone, 5g yeast powder, 10g citric acid, MnSO 4 0.1g, KH 2 PO 4 0.5g, FeSO 4 0.02g, MgSO 4 0.5g. The balance is water.

[0108] experimental method:

[0109] Group 1, Group 2, Group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com