Quartz stone resin with high stability and preparation method thereof

A high-stability, quartz stone technology, applied in the field of unsaturated polyester resin, can solve the problem of flexural strength, flexural modulus of elasticity and thermal deformation temperature, which are greatly affected by temperature, heat resistance and corrosion resistance of unsaturated polyester resin. Not good, the electron cloud distribution of phthalic anhydride is asymmetric, etc., to achieve the effect of improved surface gloss, high corrosion resistance, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

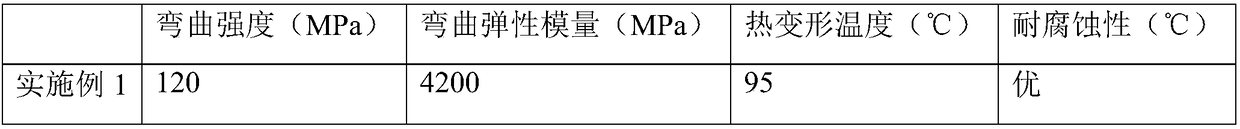

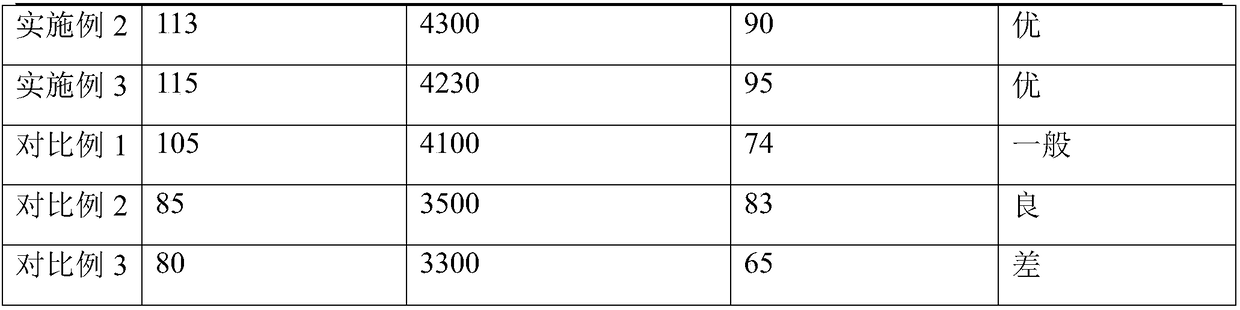

Embodiment 1

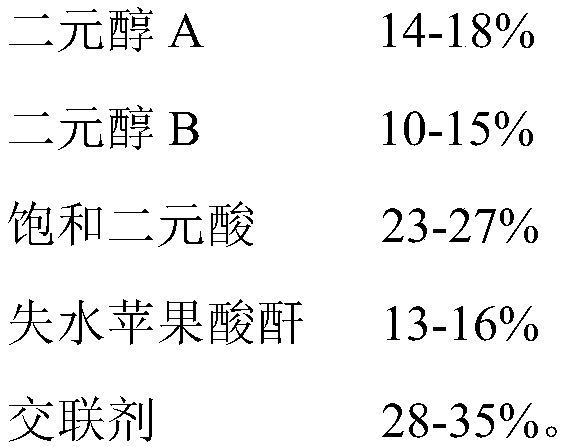

[0036] Described high stability quartz stone resin comprises following raw material:

[0037] Diethylene glycol 170g, ethylene glycol 70g, 1,4-butanediol 70g, MPO 140g, isophthalic acid 100g, phthalic anhydride 270g, dehydrated malic anhydride 220g, vinylbenzene 450g.

[0038] The specific preparation method is as follows:

[0039] (1) Under the protection of high-purity nitrogen, put 170g of diethylene glycol, 70g of glycol, 70g of 1,4-butanediol, 140g of MPO, 100g of isophthalic acid and 100PPM manganese acetate into the reaction kettle for reaction, and gradually raise the temperature to 210 Polycondensation reaction at ±5°C for 8 hours until the acid value drops to 35-40mgKOH / g.

[0040] (2) Then cool down to 160±5°C, put in 270g of phthalic anhydride, 220g of dehydrated malic anhydride and 30PPM1,4-dihydroxybenzene, gradually raise the temperature to 205±5°C for polycondensation reaction for 8 hours, until the acid value drops to 55-65mgKOH / g, decompression and vacuum ...

Embodiment 2

[0042] Described high stability quartz stone resin comprises following raw material:

[0043] Diethylene glycol 362g, glycol 142g, methyl glycol 50g, 1,4-butanediol 210g, MPO 180g, terephthalic acid 260g, phthalic anhydride 550g, dehydrated malic anhydride 450g, vinylbenzene 850g, methacrylic acid Methyl ester 150g.

[0044] The specific preparation method is as follows:

[0045] (1) Under the protection of high-purity nitrogen, put 362g of diethylene glycol, 142g of glycol, 50g of methyl ethylene glycol, 210g of 1,4-butanediol, 180g of MPO, 260g of terephthalic acid and 150PPM of antimony pentoxide into the reaction Carry out the reaction in the kettle, gradually increase the temperature to 210±5°C for polycondensation for 9 hours, until the acid value drops to 40-45mgKOH / g.

[0046] (2) Then cool down to 160±5°C, put in 550g of phthalic anhydride, 450g of dehydrated malic anhydride, 40PPM 2,5-dihydroxytoluene, 50PPM triphenyl phosphite, and gradually heat up to 205±5°C for...

Embodiment 3

[0048] Described high stability quartz stone resin comprises following raw material:

[0049] Diethylene glycol 720g, ethylene glycol 1100g, 1,4-butanediol 1040g, MPO 400g, isophthalic acid 1600g, phthalic anhydride 1420g, dehydrated malic anhydride 1800g, vinylbenzene 3680g, methyl methacrylate 320g.

[0050] The specific preparation method is as follows:

[0051] (1) Under the protection of high-purity nitrogen, put 720g of diethylene glycol, 1100g of glycol, 1040g of 1,4-butanediol, 400g of MPO, 1600g of isophthalic acid, 100PPM antimony trioxide, and 100PPM manganese acetate into the reaction kettle. For reaction, gradually increase the temperature to 210±5°C for polycondensation for 10 hours until the acid value drops to 50-55mgKOH / g.

[0052] (2) Then cool down to 160±5°C, put in 1420g of phthalic anhydride, 1800g of dehydrated malic anhydride, 40PPM pyrobic acid, and 50PPM triphenyl phosphite, and gradually heat up to 205±5°C for 8 hours of polycondensation until the aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com