Preparation method for carbon-coating nickel nano-particle reinforced silver-based composite material

A nanoparticle and carbon-coated nickel technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of uneven dispersion of the reinforcing phase, and achieve simple and convenient preparation method, simplified preparation process, Effect of good thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step, preparation of Ni+Ag catalyst precursor NiO+Ag by deposition-precipitation method 2 o

[0031] Add nickel nitrate hexahydrate and silver nitrate into deionized water at a mass ratio of 0.03:1 to prepare an aqueous solution with a molar concentration of nickel nitrate of 0.01mol / L and simultaneously contain nickel ions and silver ions, and add dropwise to the solution Molar concentration is 1.25mol / L sodium hydroxide solution to pH value is 10, and is precipitated, makes the Ni(OH) of mass ratio Ni:Ag=0.01:1 2 +Ag 2 O binary colloid, the Ni(OH) 2 +Ag 2 The O binary colloid was put into an electric constant temperature drying oven, dehydrated to complete dryness at 250 °C and nitrogen atmosphere, and then placed in a tube furnace for calcination at 300 °C for 3 hours to obtain the Ni+Ag catalyst precursor NiO+Ag 2 O powder;

[0032] The second step is to prepare carbon-coated nickel nanoparticles + silver in-situ composite powder by chemical vapor dep...

Embodiment 2

[0037] The first step, preparation of Ni+Ag catalyst precursor NiO+Ag by deposition-precipitation method 2 o

[0038] With embodiment 1;

[0039] The second step is to prepare carbon-coated nickel nanoparticles + silver in-situ composite powder by chemical vapor deposition

[0040] Except that the catalytic cracking reaction time is 2h, the carbon-coated nickel nanoparticles + silver in-situ composite powder with an average particle size of 28nm is obtained, and the yield of carbon-coated nickel nanoparticles is 0.31%, other processes, conditions and results Same as embodiment 1;

[0041] The third step is to prepare carbon-coated nickel nanoparticles reinforced silver-based composites

[0042] With embodiment 1.

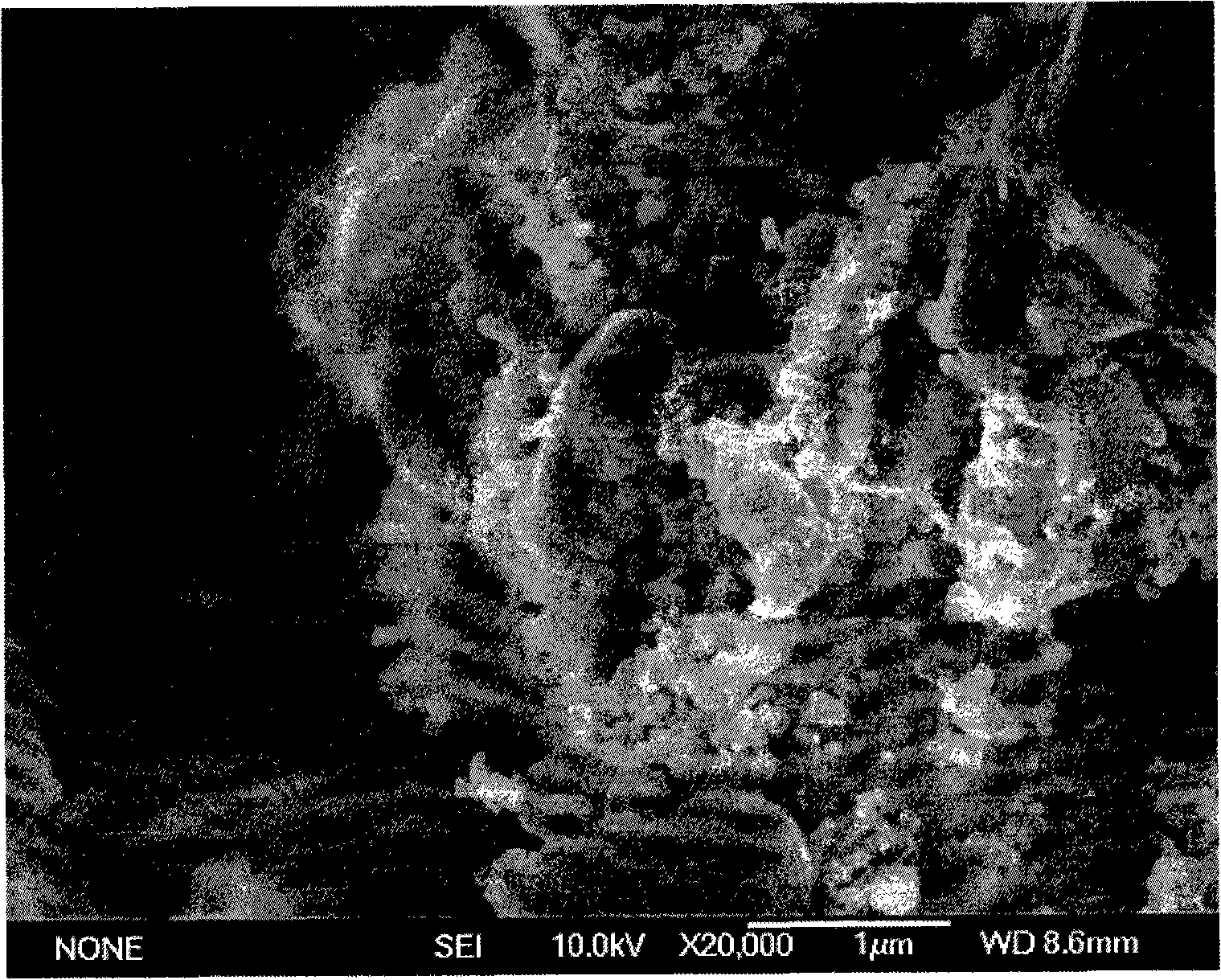

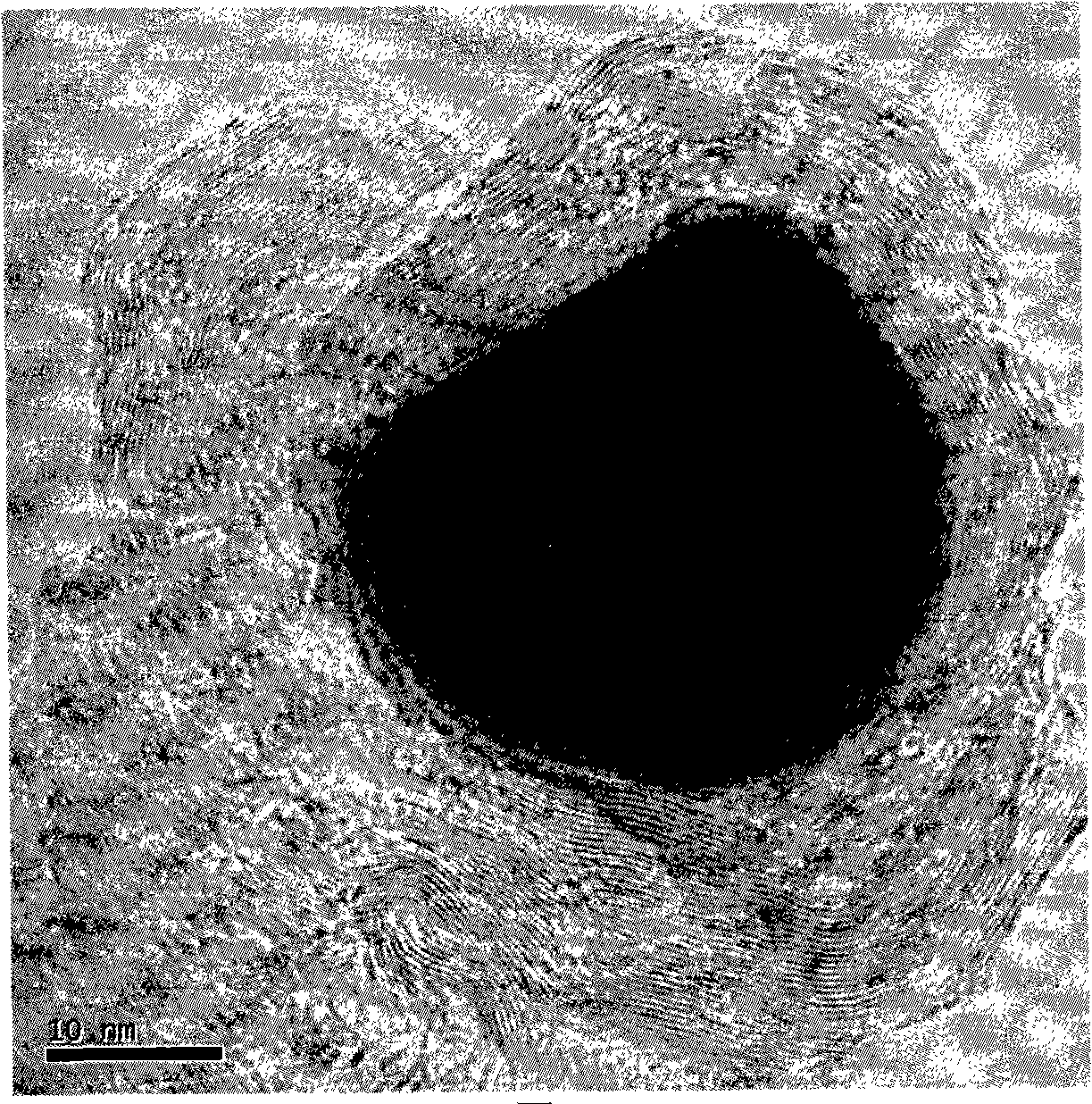

[0043] The high-resolution scanning electron micrograph of the carbon-coated nickel nanoparticles + silver in-situ composite powder obtained in this example is shown in figure 1 , where the high-resolution transmission electron micrographs of carbon-coated nick...

Embodiment 3

[0046] The first step, preparation of Ni+Ag catalyst precursor NiO+Ag by deposition-precipitation method 2 o

[0047] Add nickel nitrate hexahydrate and silver nitrate into deionized water at a mass ratio of 0.17:1 to prepare an aqueous solution containing nickel ions and silver ions with a molar concentration of nickel nitrate of 0.04 mol / L, and add dropwise to the solution Molar concentration is 1.25mol / L sodium hydroxide solution to pH value is 10, and is precipitated, makes the Ni(OH) of mass ratio Ni:Ag=0.05:1 2 +Ag 2 O binary colloid, the Ni(OH) 2 +Ag 2 The O binary colloid was dehydrated in an electric constant temperature drying oven at 150 °C and nitrogen atmosphere until it was completely dry, and then placed in a tube furnace for calcination at 400 °C for 2 hours to obtain the Ni+Ag catalyst precursor NiO+Ag 2 O powder;

[0048] The second step is to prepare carbon-coated nickel nanoparticles + silver in-situ composite powder by chemical vapor deposition

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com