Method for preparing nucleocapsid type microgel composite microsphere using polymerisable surfactant

A technology of surfactants and composite microspheres, applied in the field of materials, can solve the problem of introducing such substances into the surface of microgels to form composite microspheres with a core-shell structure. problem, to achieve good swelling and deswelling reversible characteristics, large specific surface area, and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

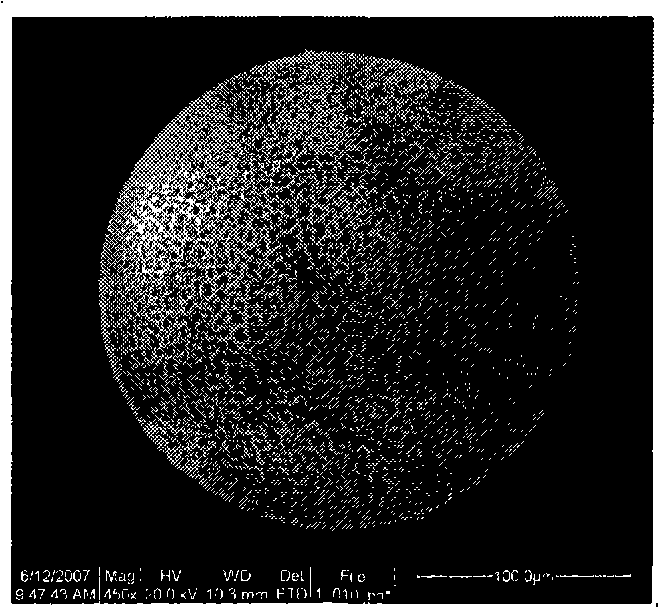

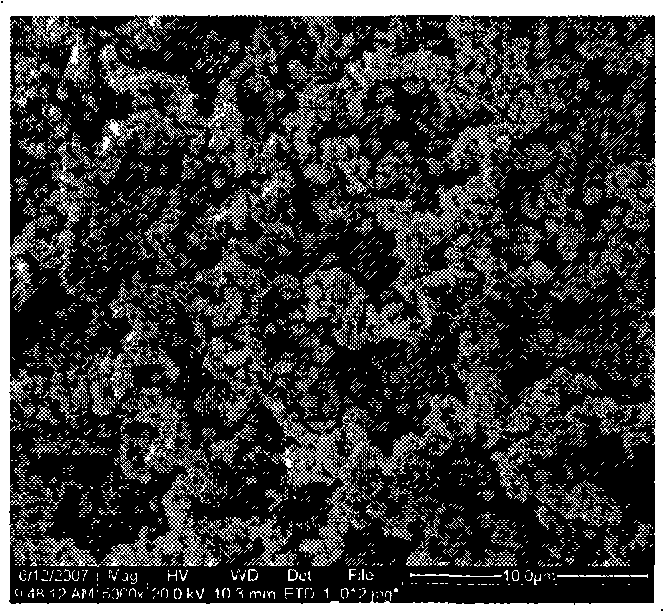

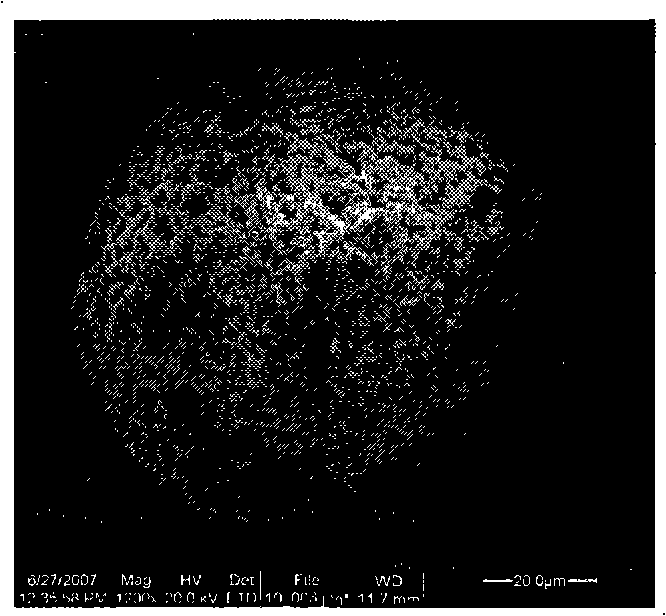

Image

Examples

Embodiment 1

[0058] Taking the polymerizable surfactant acrylamidopropyl dodecyl dimethyl ammonium bromide 0.026g as an example for preparing microgel composite microspheres as an example, other raw materials and preparation methods thereof are as follows:

[0059] 1. Preparation of oil phase

[0060] 0.52g of surfactant Span-80 was added into a beaker containing 70mL of cyclohexane, and the surfactant was mixed with cyclohexane in a weight ratio of 1:103 to form an oil phase.

[0061] 2. Preparation of uniformly dispersed oil phase

[0062] Put the oil phase prepared in step 1 into a three-necked flask, stir with a stirrer at a stirring speed of 380 rpm, and inject N at a flow rate of 2 to 3 mL / min. 2 , stirred and dispersed at 20°C for 50 minutes to prepare a uniformly dispersed oil phase.

[0063] 3. Preparation of water phase

[0064] Dissolve 1.2g of acrylamide, 0.05g of N,N'-methylenebisacrylamide, and 80mg of ammonium persulfate in 5.5mL of secondary water. The mass ratio of ami...

Embodiment 2

[0076] Taking 0.21 g of the polymerizable surfactant acrylamidopropyl dodecyl dimethyl ammonium bromide as the raw material used to prepare microgel composite microspheres as an example, other raw materials used and their preparation methods are as follows:

[0077]In step 1 of preparing the oil phase process, 0.52g of surfactant Span-80 was added to a beaker filled with 67mL of cyclohexane, and the surfactant was mixed with cyclohexane in a weight ratio of 1:100 to prepare the oil phase . In the process step 2 of preparing the uniformly dispersed oil phase, stirring and dispersing at 18°C for 60 minutes, other steps in this process step were the same as in Example 1 to prepare a uniformly dispersed oil phase. In step 3 of the water phase preparation process, 1.2g of acrylamide, 0.04g of N,N'-methylenebisacrylamide, and 80mg of ammonium persulfate were dissolved in 5.5mL of secondary water, and the secondary water was mixed with acrylamide, N , The mass ratio of N'-methylen...

Embodiment 3

[0079] Taking the polymerizable surfactant acrylamidopropyl dodecyl dimethyl ammonium bromide 0.5g as an example for preparing microgel composite microspheres as an example, other raw materials and preparation methods thereof are as follows:

[0080] In step 1 of preparing the oil phase process, 0.52g of surfactant Span-80 was added to a beaker containing 76.8mL of cyclohexane, and the surfactant was mixed with cyclohexane in a weight ratio of 1:115 to prepare an oil Mutually. In the process step 2 of preparing the uniformly dispersed oil phase, stir and disperse at 30° C. for 30 minutes. Other steps in this process step are the same as in Example 1 to prepare a uniformly dispersed oil phase. In step 3 of the water phase preparation process, 1.2 g of acrylamide, 0.06 g of N, N'-methylenebisacrylamide, and 80 mg of ammonium persulfate were dissolved in 5.5 mL of secondary water, and the secondary water was mixed with acrylamide, N , The mass ratio of N'-methylenebisacrylamide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com