Poly-SiGe gate three-dimensional strain CMOS integrated component and preparation method thereof

An integrated device, three-dimensional technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problem of low speed of three-dimensional integrated circuits, achieve the effect of ensuring AC and DC electrical performance, improving performance, and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

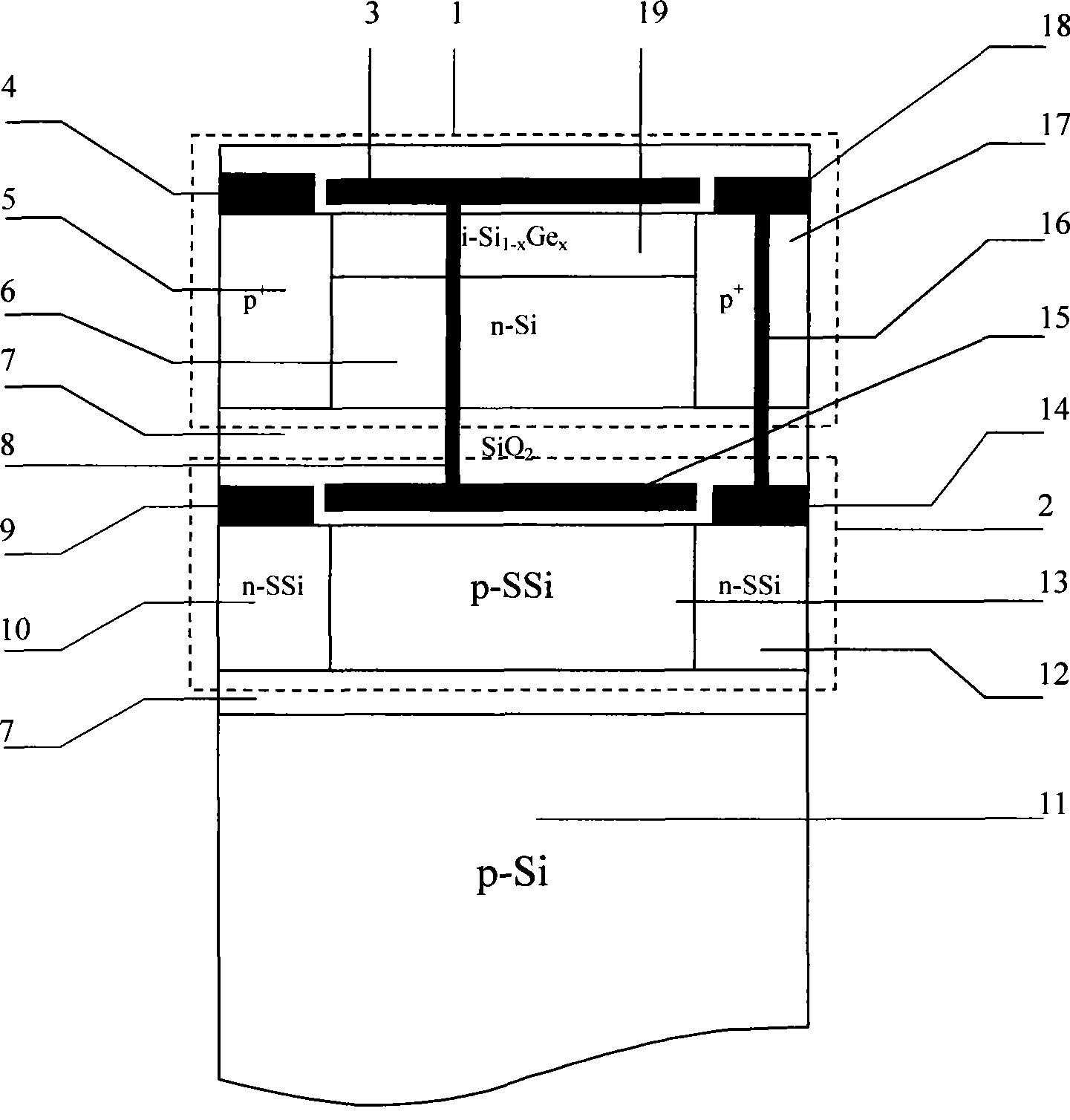

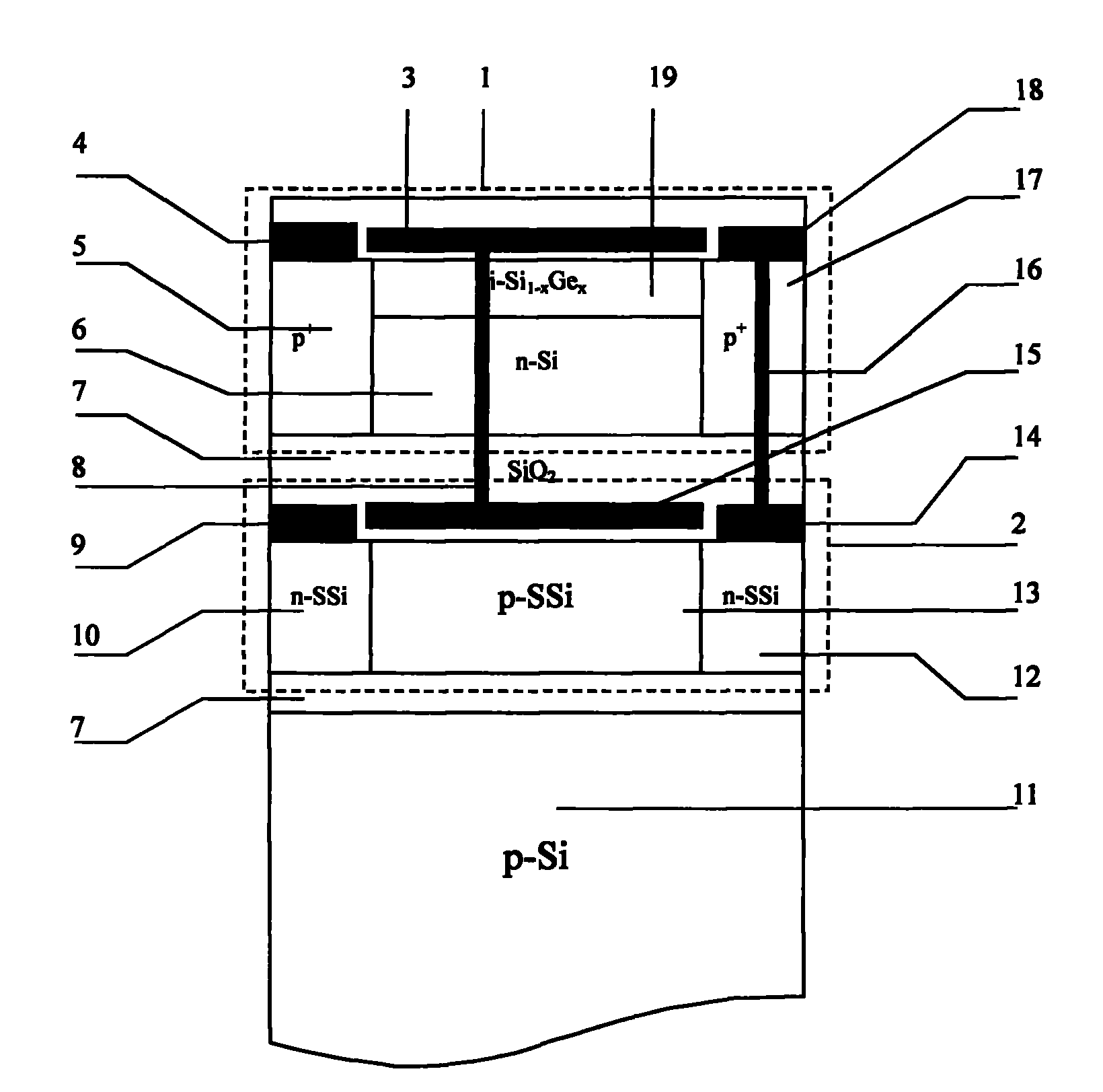

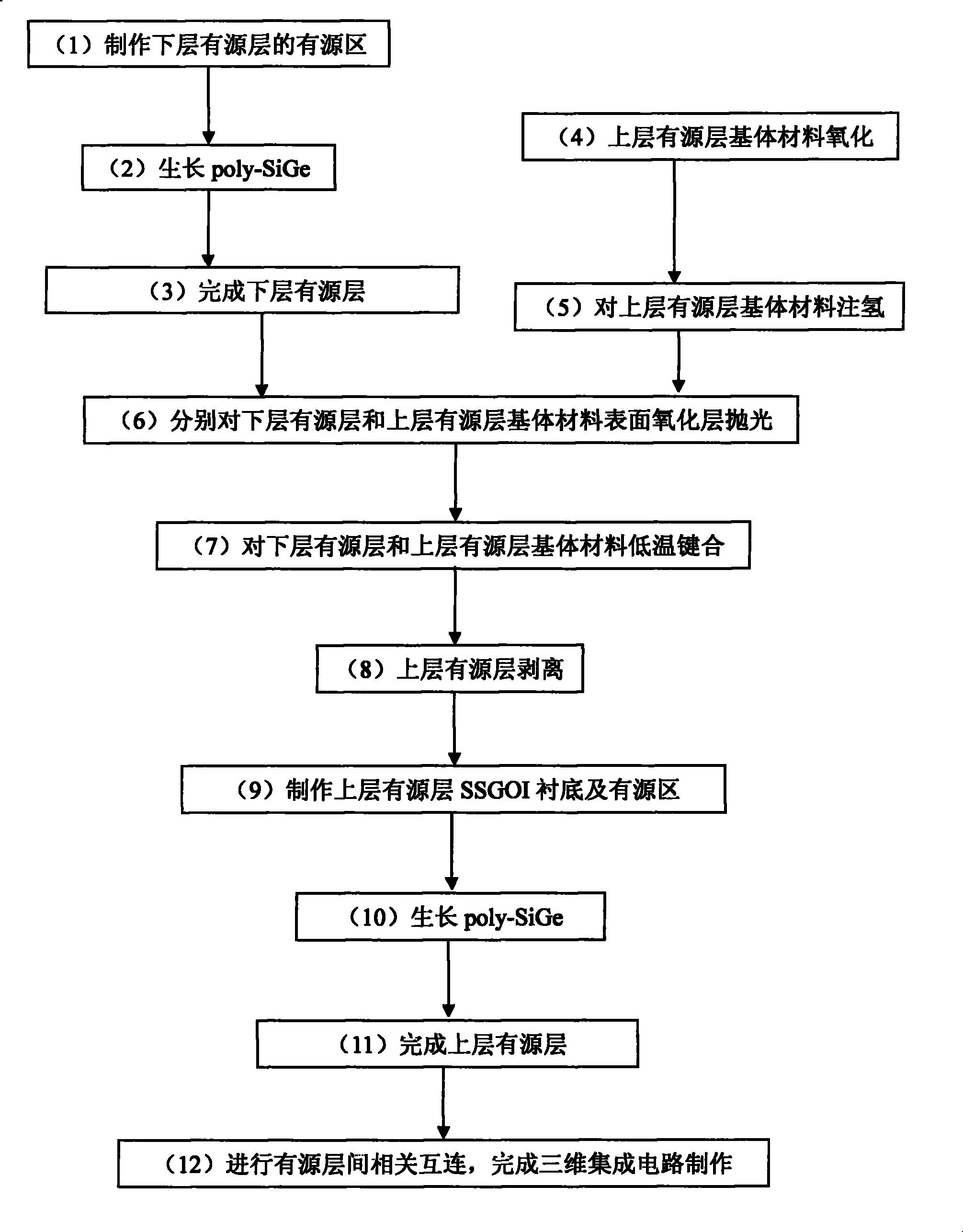

[0043] Embodiment 1: The steps of making a Poly-SiGe gate three-dimensional strained CMOS integrated device with a conductive channel of 65nm are as follows:

[0044] (1) Select SSOI substrates with stress>1Gpa;

[0045] (2) On the SSOI substrate, the active area is produced by oxidation, photolithography, ion implantation and other processes;

[0046] (3) Using ultra-high vacuum chemical vapor deposition UHVCVD method, a layer of p-type Poly-SiGe is deposited on the active region as the gate, and the doping concentration is >10 20 cm -3 , Ge composition is 0.2;

[0047] (4) On the Poly-SiGe layer, through photolithography Poly-SiGe layer-passivation-ion implantation-lithography lead hole-polysilicon wiring-low temperature deposition of SiO 2 The dielectric layer is used to make a strained Si nMOSFET device structure and interconnection with a Poly-SiGe gate with a conductive channel of 65nm;

[0048] (5) Deposit SiO on the surface of the lower active layer 2 medium layer...

Embodiment 2

[0059] Embodiment 2: The steps of making a Poly-SiGe gate three-dimensional strained CMOS integrated device with a conductive channel of 90nm are as follows:

[0060] (1) Select SSOI substrates with stress>1Gpa;

[0061] (2) On the SSOI substrate, the active area is produced by oxidation, photolithography, ion implantation and other processes;

[0062] (3) Using the reduced pressure chemical vapor deposition RPCVD method, a layer of p-type Poly-SiGe is deposited on the active region as the gate, and the doping concentration is >10 20 cm -3 , Ge composition is 0.05;

[0063] (4) On the Poly-SiGe layer, through photolithography Poly-SiGe layer-passivation-ion implantation-lithography lead hole-polysilicon wiring-low temperature deposition of SiO 2 The dielectric layer is used to make a strained Si nMOSFET device structure and interconnection with a poly-SiGe gate with a conductive channel of 90nm;

[0064] (5) Deposit SiO on the surface of the lower active layer 2 medium la...

Embodiment 3

[0075] Embodiment 3: The steps of making a Poly-SiGe gate three-dimensional strained CMOS integrated device with a conductive channel of 130nm are as follows:

[0076] (1) Select SSOI substrates with stress>1Gpa;

[0077] (2) On the SSOI substrate, the active area is produced by oxidation, photolithography, ion implantation and other processes;

[0078] (3) Using ultraviolet photochemical vapor deposition UVCVD method, deposit a layer of p-type Poly-SiGe on the active region, as the gate, doping concentration > 10 20 cm -3 , Ge composition is 0.3;

[0079] (4) On the Poly-SiGe layer, through photolithography Poly-SiGe layer-passivation-ion implantation-lithography lead hole-polysilicon wiring-low temperature deposition of SiO 2 The dielectric layer is used to make a strained Si nMOSFET device structure and interconnections with a Poly-SiGe gate with a conductive channel of 130nm;

[0080] (5) Deposit SiO on the surface of the lower active layer 2 medium layer;

[0081] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com