Freezing flour-dough improver and uses thereof

A technology of frozen dough and improver, which is applied in application, dough processing, pre-baked dough processing, etc., and can solve the problems of unsuitable frozen dough quality improvement, aging, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Preparation of frozen dough improver

[0057] Weigh each component according to the ratio of each raw material shown in Table 3 below, and then add each raw material component into the mixer and mix for 30 minutes; after the mixing is completed, take out the raw materials in the mixer, weigh, and make a total of frozen The dough improver is 1kg, and finally the PP / Al foil / PE composite bag is divided into 500g / bag or 1000g / bag to obtain the finished product:

[0058] table 3

[0059] raw material

percentage

alpha-amylase

0.2%

Pentosanase

0.3%

Diacetyltartaric acid monoglyceride

5%

5%

Sodium Stearoyl Lactate

3%

1%

0.1%

Vitamin C

3%

0.2%

Hemicellulase

0.2%

3%

Transglutaminase

0.2%

Sodium Alginate

6%

3%

40%

10%

margin

[0060] Weigh each component according to the raw material ratio shown in Table 4 below, and then add each raw material...

Embodiment 2

[0063] Example 2: The effect of the frozen dough improver of the present invention on bread produced by the frozen dough method

[0064] The experiment process is as follows:

[0065] 1. The purpose of the experiment

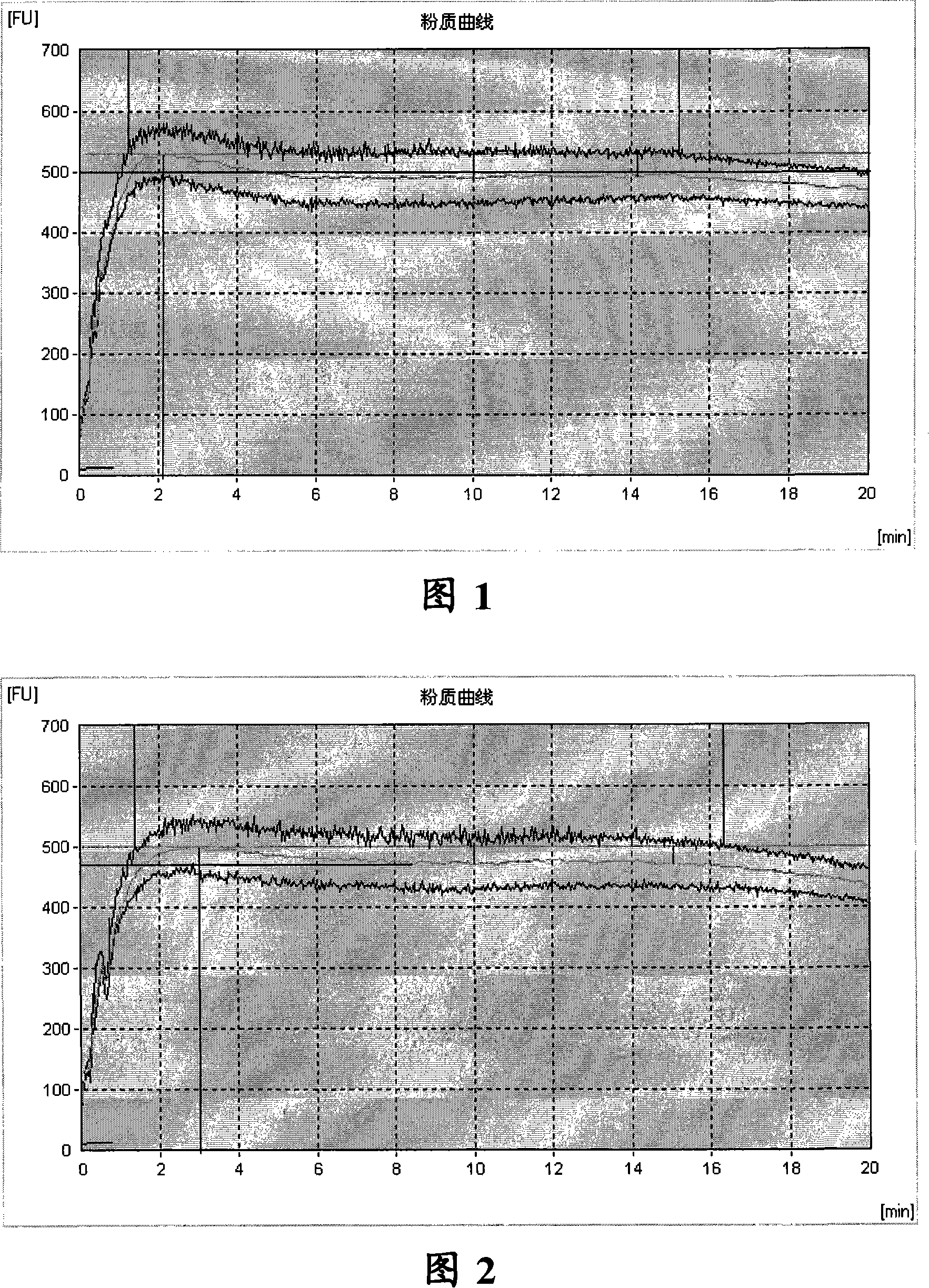

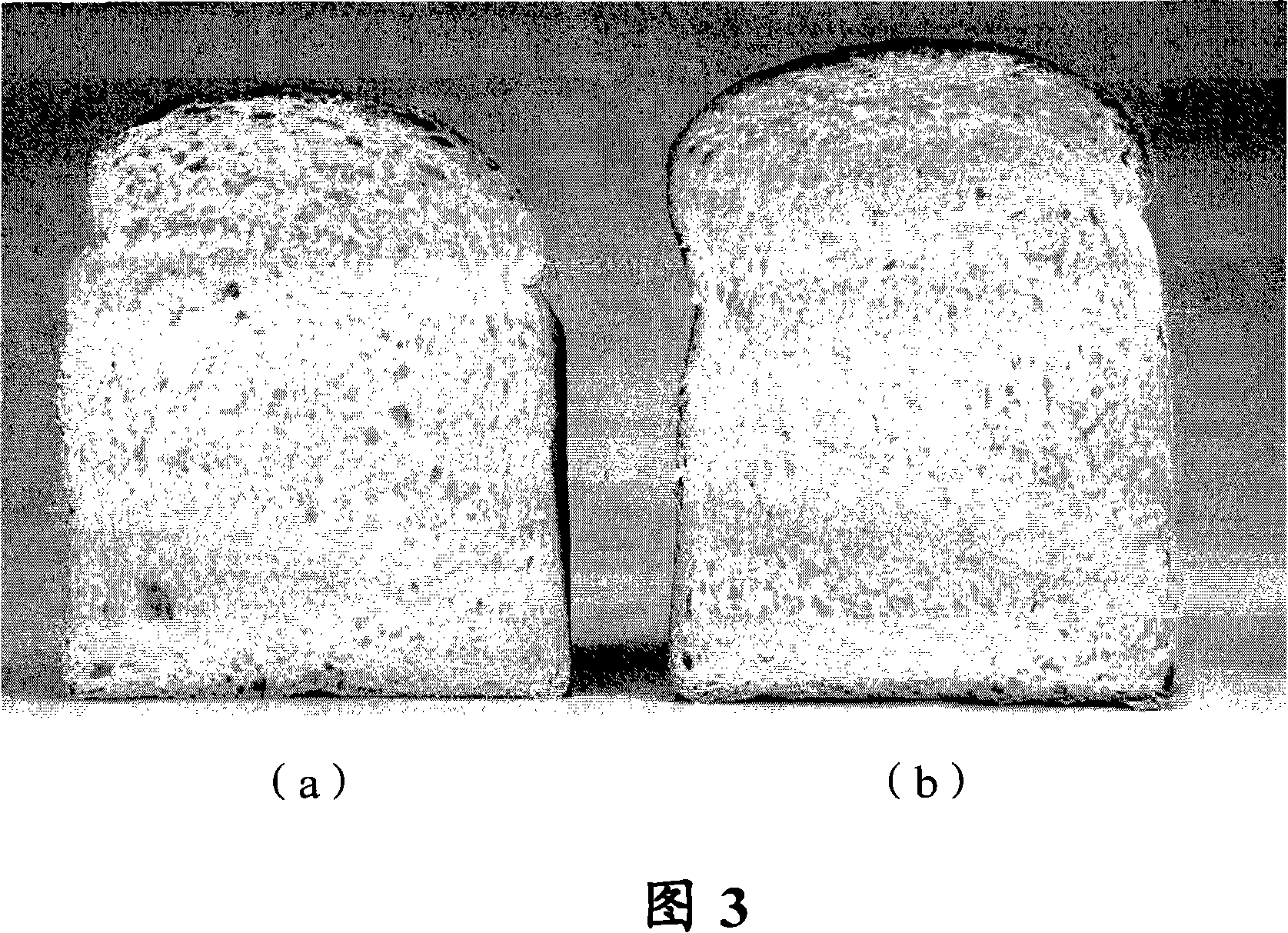

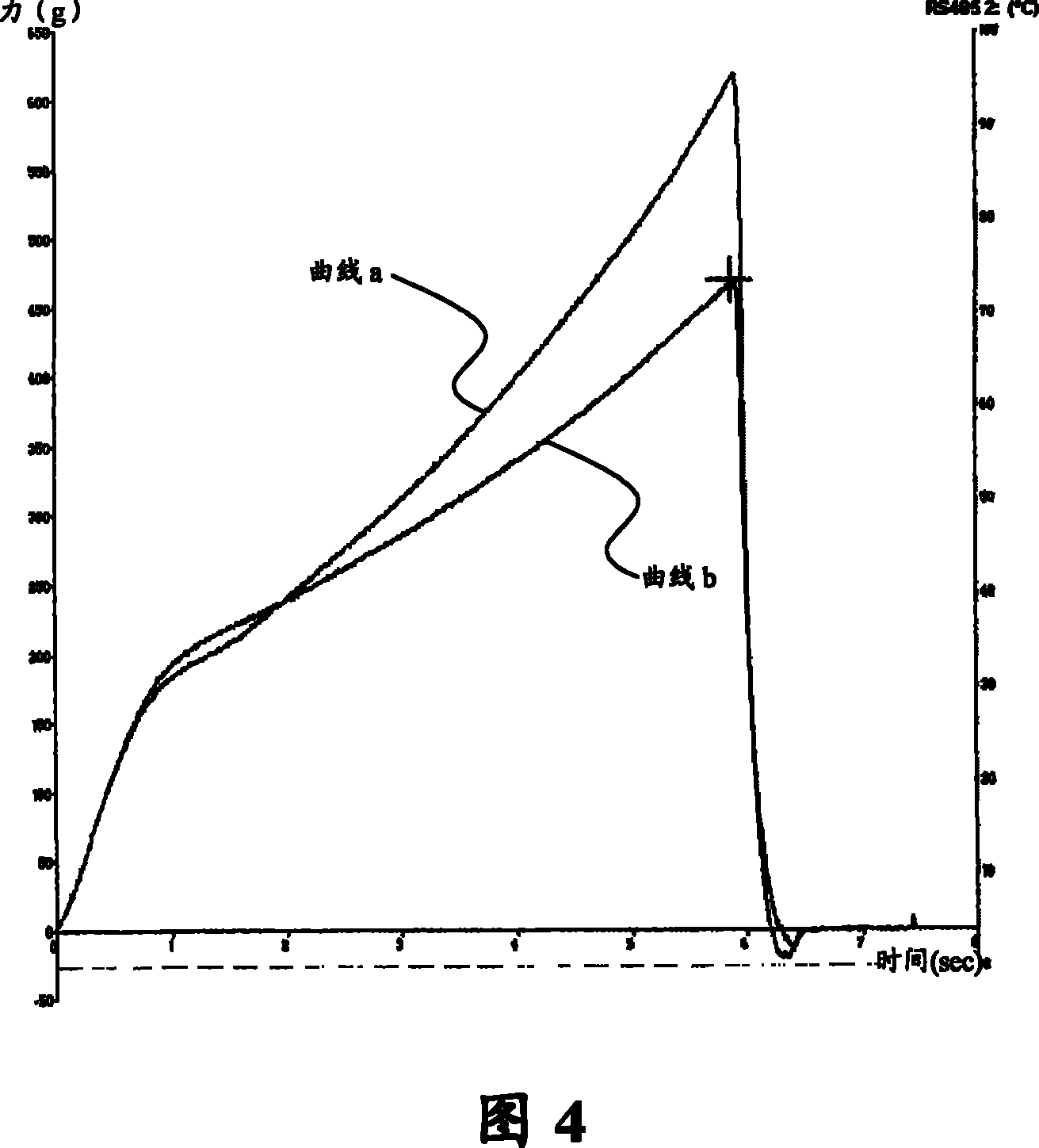

[0066] A baking test was carried out on the bread prepared with the frozen dough improver of the present invention to test the effect of the frozen dough improver of the present invention on the increase in bread volume, and the powder quality test was used to detect the rheological effect of the improver on the dough and the quality of use. The composition analyzer performs a hardness test on the bread after storage for 7 days (that is, to detect the aging of the bread).

[0067] 2. Test group

[0068] Edit

number

sample name

Addition of frozen dough improver

Add amount (add by flour)

1

Blank (frozen dough without the improver of the present invention)

/

2

Frozen dough using the frozen dough improver of the present invention

2%

[0069] Three, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com