Method for preparing deep profile modification cationic polymer microlatex from reverse microemulsion

A polymer and cationic technology, which is applied in the cationic deep control polymer microlatex and its synthesis field, can solve the problems of difficult injectability, inefficiency, and limited development, and achieve the effect of strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

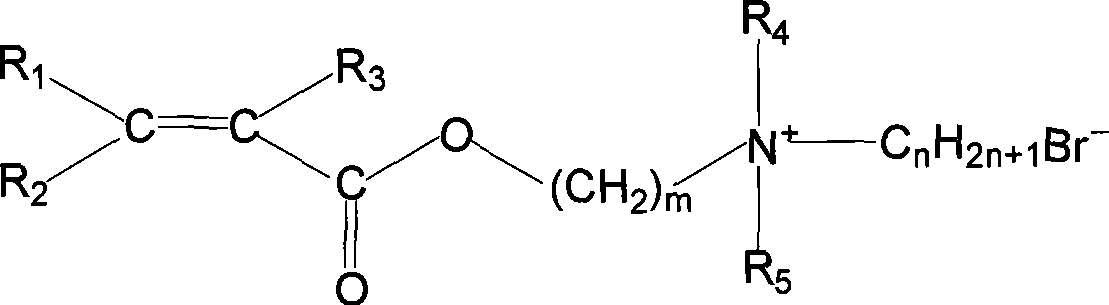

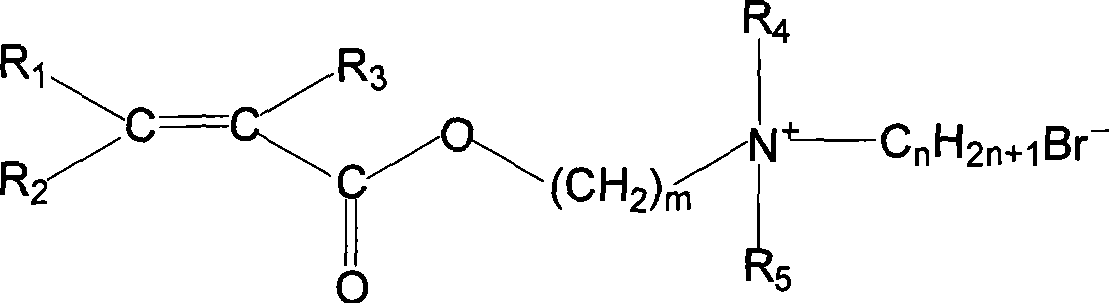

Method used

Image

Examples

Embodiment 1

[0024] In the reaction vessel, add 80g of white oil and 40g of surfactant in a certain proportion, control the HLB value of the surfactant mixture between 9.2, control the temperature at 40°C, stir at 800rpm, and stir for 1.5h; according to the amount Acrylamide (monomer A) and trimethyl (acryloyloxyethyl) ammonium bromide (monomer B) were formulated into 15 g of aqueous solution, and the concentration of the solution was between 55 wt % (the molar ratio of A to B was 9:1 ). Then, under the condition of stirring again, the aqueous monomer solution was slowly added dropwise, and the stirring was continued for 5 hours, and the temperature of the solution was controlled between 40°C. Continue to stir, control the stirring speed between 300rpm, pass high-purity nitrogen for 30min, first add 0.03% aqueous solution of N,N-methylenebisacrylamide containing sodium acetate, and then add 0.05g of water-soluble free radical initiator V50, Continue to pass nitrogen to react for 5h, and o...

Embodiment 2

[0026] In the reaction vessel, add 80g of white oil and 40g of surfactant in a certain proportion, control the HLB value of the surfactant mixture between 8.8, control the temperature at 40°C, stir at 800rpm, and stir for 1.5h; according to the amount Acrylamide (monomer A) and trimethyl (acryloyloxyethyl) ammonium bromide (monomer B) were formulated into 20 g of aqueous solution, and the concentration of the solution was between 55 wt % (the molar ratio of A to B was 7:1 ). Then, under the condition of stirring again, the aqueous monomer solution was slowly added dropwise, and the stirring was continued for 5 hours, and the temperature of the solution was controlled between 40°C. Continue to stir, control the stirring speed between 300rpm, pass high-purity nitrogen for 30min, first add 0.03% aqueous solution of N,N-methylenebisacrylamide containing sodium acetate, and then add 0.15g of water-soluble free radical initiator V50, Continue to pass nitrogen to react for 5h, and o...

Embodiment 3

[0028] In the reaction vessel, add 80g of white oil and 40g of surfactant in a certain proportion, control the HLB value of the surfactant mixture between 8.8, control the temperature at 40°C, stir at 800rpm, and stir for 1.5h; according to the amount Acrylamide (monomer A) and trimethyl (acryloyloxyethyl) ammonium bromide (monomer B) were formulated into 20 g of aqueous solution, and the concentration of the solution was between 55 wt % (the molar ratio of A to B was 7:1 ). Then, under the condition of stirring again, the aqueous monomer solution was slowly added dropwise, and the stirring was continued for 5 hours, and the temperature of the solution was controlled between 40°C. Continue to stir, control the stirring speed between 300rpm, pass high-purity nitrogen for 30 minutes, first add 0.03% formaldehyde phenol aqueous solution containing sodium acetate, then add 0.1g of water-soluble free radical initiator V50, continue to pass nitrogen for 5 hours, and obtain transpare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com