Preparation method and application of novel titanium silicalite molecular sieve

A titanium-silicon molecular sieve, a new type of technology, applied in molecular sieve catalysts, molecular sieves and alkali exchange compounds, organic chemical methods, etc., can solve the problems of weak catalytic activity, small mesoporous specific surface, low carbon dioxide conversion efficiency, etc., to improve catalytic performance. , strong adsorption performance, the effect of alleviating the shortage of petroleum resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

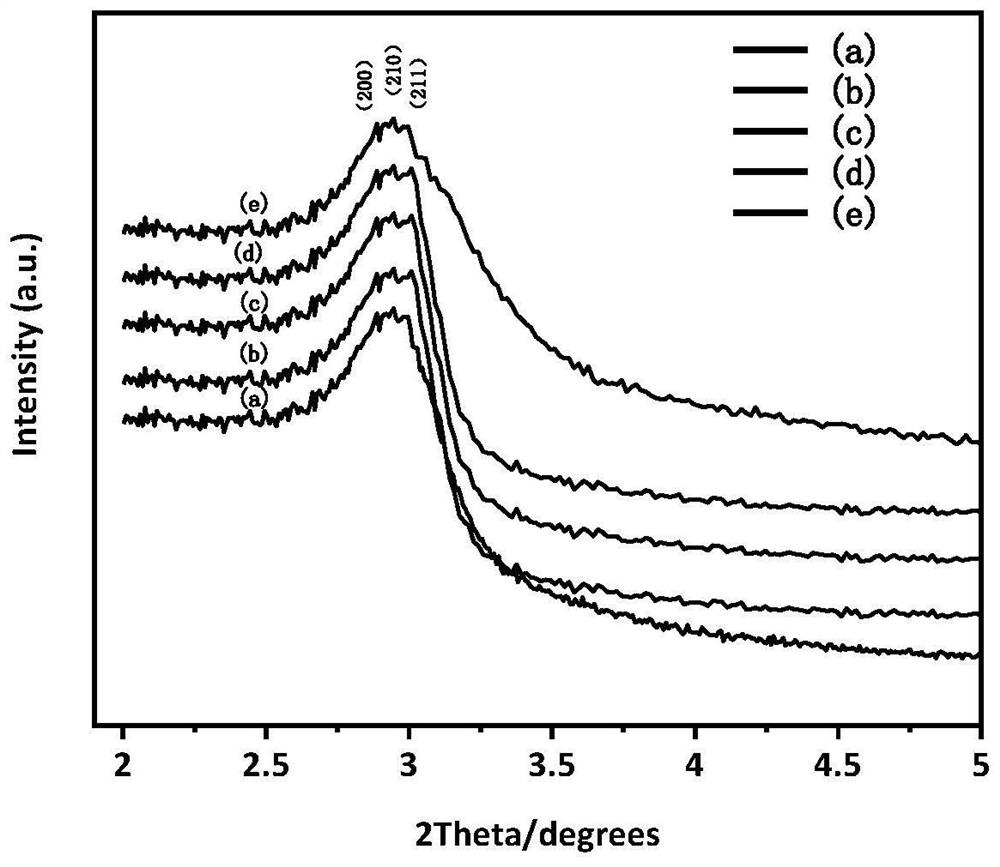

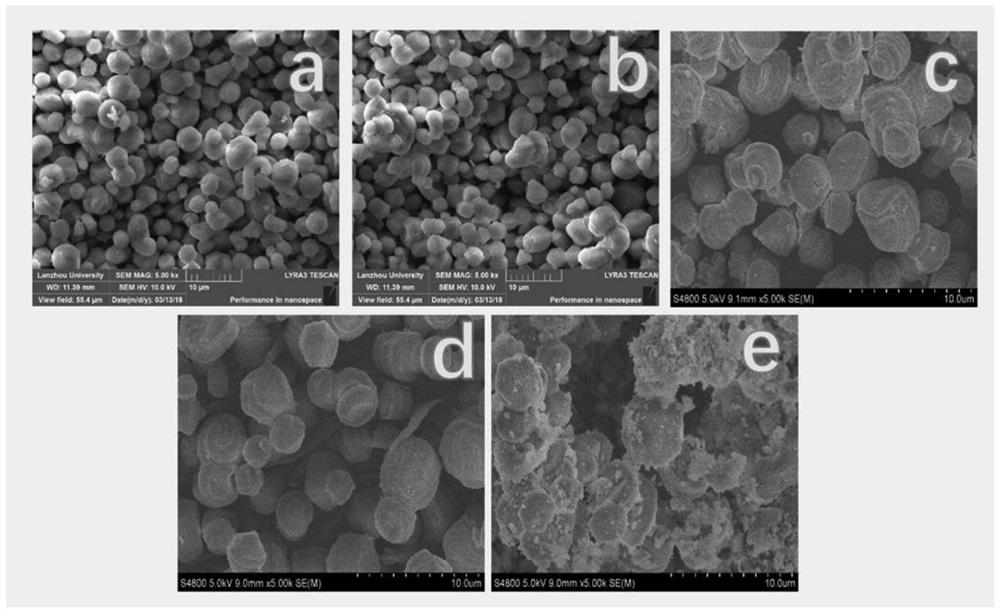

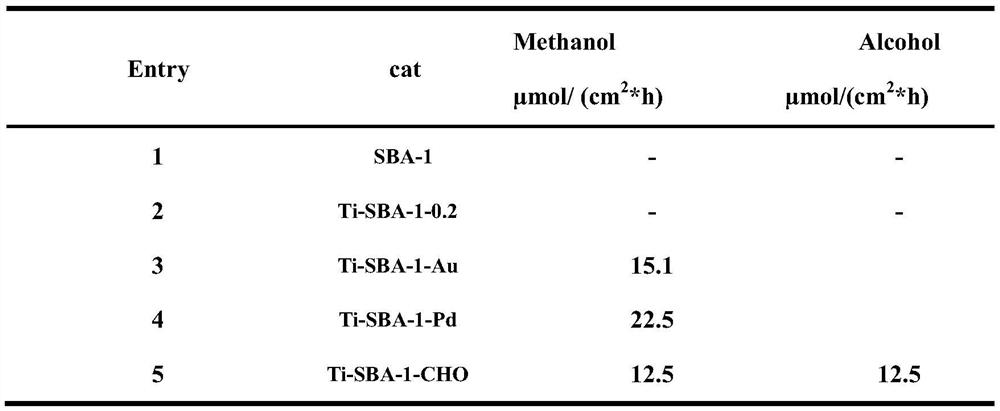

[0030] Preferably, 5.28g of cetyltrimethylammonium bromide (CTABr) is weighed, dissolved in 325.7ml of deionized water, and ultrasonicated for 15 minutes at a temperature of 313K. Obtain a homogeneous clear solution, then add 167.2ml of 37% hydrochloric acid, and then slowly add a certain amount of tetrabutyl titanate (TBOT) solution dissolved in isopropanol to the above solution under strong mechanical stirring , and then cooled to 273k. After 30 minutes, under vigorous stirring, slowly add a certain amount of ethyl orthosilicate which was cooled to 273k in advance into the above solution dropwise, after 5 minutes, stop stirring, and crystallize under static conditions for 6 hours, and then The above solution was suction filtered and washed with acetone. Place the oven at 100°C, take it out to a mortar after 4 hours, grind it to a uniform powder, put it into a muffle furnace, heat up to 873K for 4 hours and calcinate for 4 hours to obtain the product Ti-SBA-1. The molar rat...

Embodiment 2

[0033] Preferably, (1) 5.28g of cetyltrimethylammonium bromide (CTABr) was weighed, dissolved in 325.7ml of deionized water, and ultrasonicated for 15 minutes at a temperature of 313K. Obtain a homogeneous clear solution, then add 167.2ml of 37% hydrochloric acid, and then slowly add a certain amount of tetrabutyl titanate (TBOT) solution dissolved in isopropanol to the above solution under strong mechanical stirring , and then cooled to 273k. After 30 minutes, under vigorous stirring, slowly add a certain amount of ethyl orthosilicate which was cooled to 273k in advance into the above solution dropwise, after 5 minutes, stop stirring, and crystallize under static conditions for 6 hours, and then The above solution was suction filtered and washed with acetone. Place the oven at 100°C, take it out to a mortar after 4 hours, grind it to a uniform powder, put it into a muffle furnace, heat up to 873K for 4 hours and calcinate for 4 hours to obtain the product Ti-SBA-1. The mola...

Embodiment 3

[0036] Preferably, (1) 5.28g of cetyltrimethylammonium bromide (CTABr) was weighed, dissolved in 325.7ml of deionized water, and ultrasonicated for 15 minutes at a temperature of 313K. Obtain a homogeneous clear solution, then add 167.2ml of 37% hydrochloric acid, and then slowly add a certain amount of tetrabutyl titanate (TBOT) solution dissolved in isopropanol to the above solution under strong mechanical stirring , and then cooled to 273k. After 30 minutes, under vigorous stirring, slowly add a certain amount of ethyl orthosilicate which was cooled to 273k in advance into the above solution dropwise, after 5 minutes, stop stirring, and crystallize under static conditions for 6 hours, and then The above solution was suction filtered and washed with acetone. Place the oven at 100°C, take it out to a mortar after 4 hours, grind it to a uniform powder, put it into a muffle furnace, heat up to 873K for 4 hours and calcinate for 4 hours to obtain the product Ti-SBA-1. The mola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com