Heterogeneous catalytic oxidation catalyst, preparation method and method for treating phenolic wastewater

A heterogeneous catalytic oxidation and catalyst technology, applied in the direction of oxidation water/sewage treatment, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of high cost, achieve low cost, avoid Metal loss, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

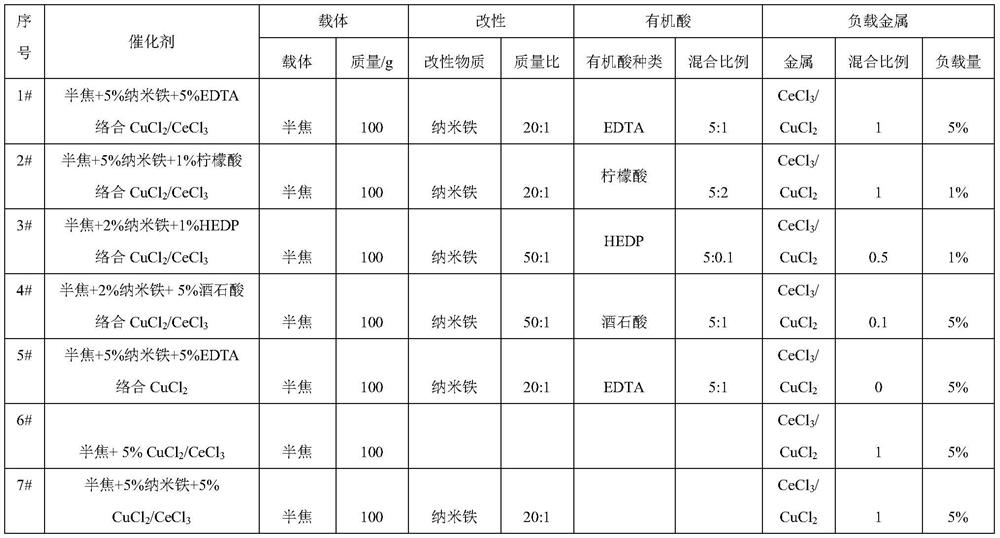

preparation example Construction

[0048] The preparation method of heterogeneous catalytic oxidation catalyst of the present invention comprises the following steps: add organic acid complexed metal copper chloride or organic acid complexed bimetallic copper chloride + cerium chloride, add carrier impregnation under nitrogen atmosphere, organic The impregnation mass ratio of acid-complexed metal copper chloride or organic acid-complexed bimetallic copper chloride + cerium chloride and modified semi-coke carrier is 1: (0.1-5), preferably 1: (1-2), impregnated The time is 10 to 240 minutes, preferably 60 to 120 minutes; then the obtained solid is dried and calcined, preferably at 60 to 150°C for 1 to 5 hours, and then calcined at 300 to 400°C for 3 to 5 hours to obtain a heterogeneous catalytic oxidation catalyst.

[0049] In another aspect, the aforementioned heterogeneous catalytic oxidation catalyst is used for a treatment process for dephenolizing and ammonia removal of phenol-containing wastewater, comprisin...

preparation example 1

[0064] Preparation example 1: Preparation of 1# catalyst (semi-coke+5% nano-iron+5% ethylenediaminetetraacetic acid complexed CuCl 2 / CeCl 3 )

[0065] Take 100g of semi-coke (SCe) and mix it with concentrated sulfuric acid and concentrated nitric acid according to its volume at a ratio of 1:1:1, stir for 2 hours, centrifuge at 5000r / min to remove the acid solution, then wash with water until neutral, and take the pretreated SCe and nano Zero-valent iron is mixed according to the mass ratio of 20:1, and deionized water is added to prepare a mixed solution with a mass concentration of 10%. Ultrasonic at 60°C for 120min, and then placed in a constant temperature drying oven at 75°C to dry to obtain a slurry, take the slurry The pellets were compressed to 5mm particles and dried at 105°C. The particles were placed in a titanium alloy oxidation reaction tube, water vapor was introduced at 10 mL / min, the reaction temperature was controlled at 180° C. for 5 h, and the carrier was ...

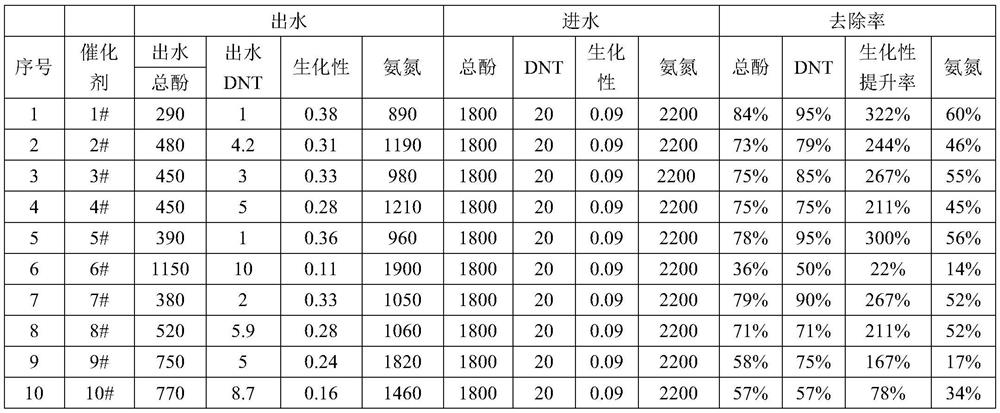

Embodiment 1

[0071] Embodiment 1: DNT wastewater treatment (1# catalyst)

[0072] Adjust the pH of the DNT wastewater to 4. According to the COD of the wastewater, add the amount of hydrogen peroxide so that the molar ratio of hydrogen peroxide to COD is 1, pass it into the catalytic oxidation reactor, and add 1# catalyst. The reaction temperature is 80°C and the space velocity is 2h-1. The reaction pressure is 0.5MPa;. Nitrogen is introduced to dilute the oxygen in the exhaust gas of the reaction tower so that the oxygen concentration is below 4%; the pH value of the treated wastewater is adjusted to 12 to form free ammonia, and the diluted exhaust gas is blown off the reaction product water to The ammonia nitrogen is volatilized and removed. The total phenol content in the effluent was 290mg / L, with a removal rate of 84%; the DNT in the effluent was 1mg / L, with a removal rate of 95%; the biochemical property increased from 0.09 to 0.38, and the ammonia nitrogen content decreased to 890m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com