Nitrendipine self-emulsification soft capsules and preparation method thereof

A technology of nitrendipine and self-microemulsification, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, and drug delivery. Effects of low bioavailability, increased bioavailability, and reduced disparity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

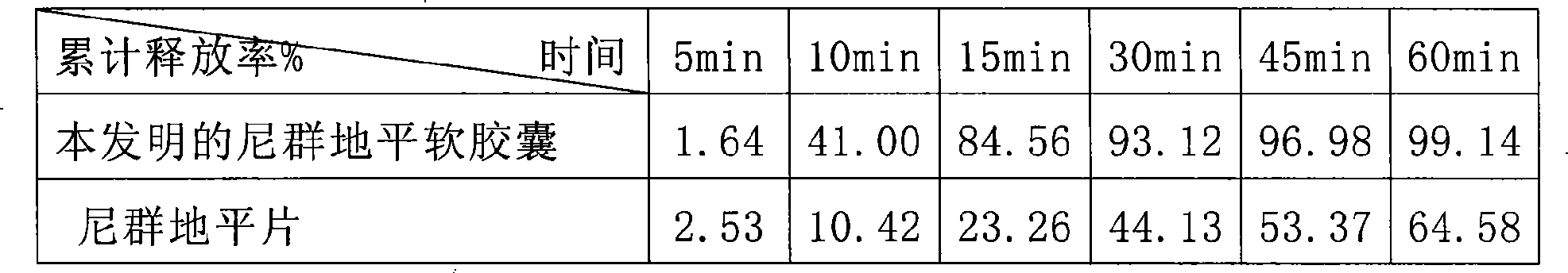

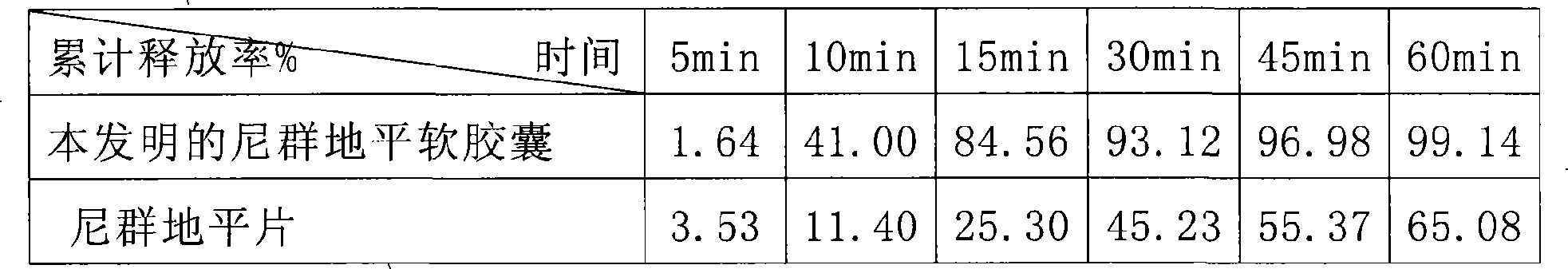

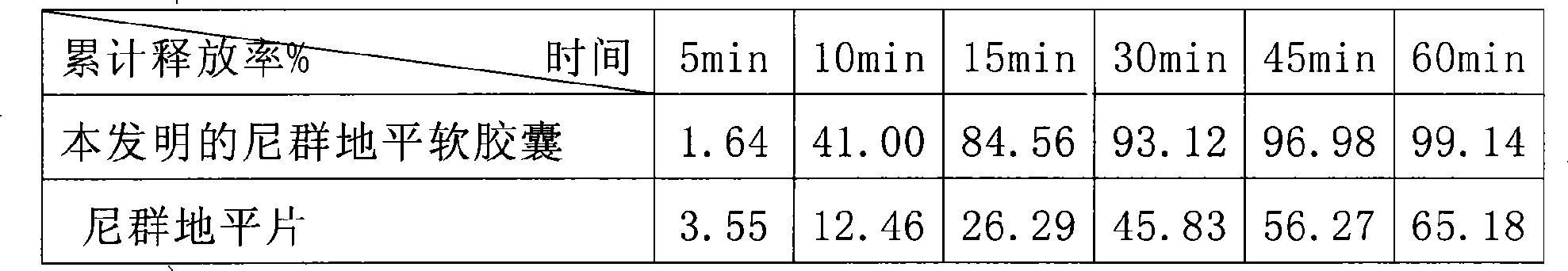

Examples

Embodiment 1

[0028] Embodiment one: a kind of nitrendipine self-microemulsifying soft capsule of the present invention and preparation method thereof, adopt following processing steps: its component (prescription amount) ratio is by weight:

[0029] Preparation of the shell fluid:

[0030] First, weigh 900 parts of gelatin in the prescribed amount; add 200 parts of glycerin; 200 parts of sorbitol; 15 parts of titanium dioxide, 1.0 part of pigment, after stirring evenly, filter (70 mesh), vacuum defoaming, vacuum degree -0.07MPa, keep warm at 68°C (holding time), and obtain the capsule shell liquid, the rotational viscosity of the capsule shell liquid It is 260mPa.s, put it into the barrel for standby.

[0031] Preparation of content solution:

[0032]Then weigh 2 parts of nitrendipine, 12 parts of ethanol, 20 parts of propylene glycol, 80 parts of hydrogenated castor oil, and 6 parts of medium-chain fatty acid triacylglycerol in the homogeneous emulsification pot, heat to 40 °C, and heat...

Embodiment 2

[0040] A kind of nitrendipine self-microemulsifying soft capsule of the present invention and preparation method thereof, adopt following process step: its component (recipe quantity) ratio is by weight:

[0041] Preparation of the shell fluid:

[0042] First, weigh 1000 parts of gelatin in the prescribed amount; place 220 parts of glycerin; 220 parts of sorbitol; 18 parts of titanium dioxide, 1.2 parts of pigment, after stirring evenly, filter (80 mesh), vacuum defoaming, vacuum degree -0.08MPa, heat preservation at 60°C, (holding time), and obtain the capsule shell liquid, the rotation of the capsule shell liquid The viscosity is 250mPa.s, put it into the barrel for standby.

[0043] Preparation of content solution:

[0044] Then weigh 3 parts of nitrendipine, 18 parts of ethanol, 30 parts of polyethylene glycol (400), 100 parts of phospholipids, and 20 parts of ethyl linoleate in the homogeneous emulsification pot, and heat to 45 ° C. Heating time: 1.5h, stirring to diss...

Embodiment 3

[0052] A kind of nitrendipine self-microemulsifying soft capsule of the present invention and preparation method thereof, adopt following process step: its component (recipe quantity) ratio is by weight:

[0053] Preparation of the shell fluid:

[0054] First, weigh 1200 parts of gelatin in the prescribed amount; place 240 parts of glycerin; 260 parts of sorbitol; 20 parts of titanium dioxide, 1.5 parts of pigment, after stirring evenly, filter (75 mesh), vacuum defoaming, vacuum degree -0.06MPa, heat preservation (holding time) at 72°C, and obtain the capsule shell liquid, the rotational viscosity of the capsule shell liquid If it is greater than 280mPa.s, put it into a barrel for use.

[0055] Preparation of content solution:

[0056] Then weigh 4 parts of nitrendipine, 25 parts of ethanol, 35 parts of propylene glycol, 120 parts of phospholipids, and 35 parts of ethyl linoleate in the homogeneous emulsification pot, heat to 47°C, heating time: 2.0h, Stir to dissolve the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com