Positive temperature coefficient macromolecule composite material for temperature sensing cable and preparation method

A positive temperature coefficient and composite material technology, applied to thermometers, thermometers, and electrical devices that use directly heat-sensitive electric/magnetic elements, can solve NTC characteristic deterioration, damage, and affect the repeatability of temperature-sensing cables, etc. problem, to achieve the effect of simple processing method, high economy and application prospect, high structural stability and repeatability of PTC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

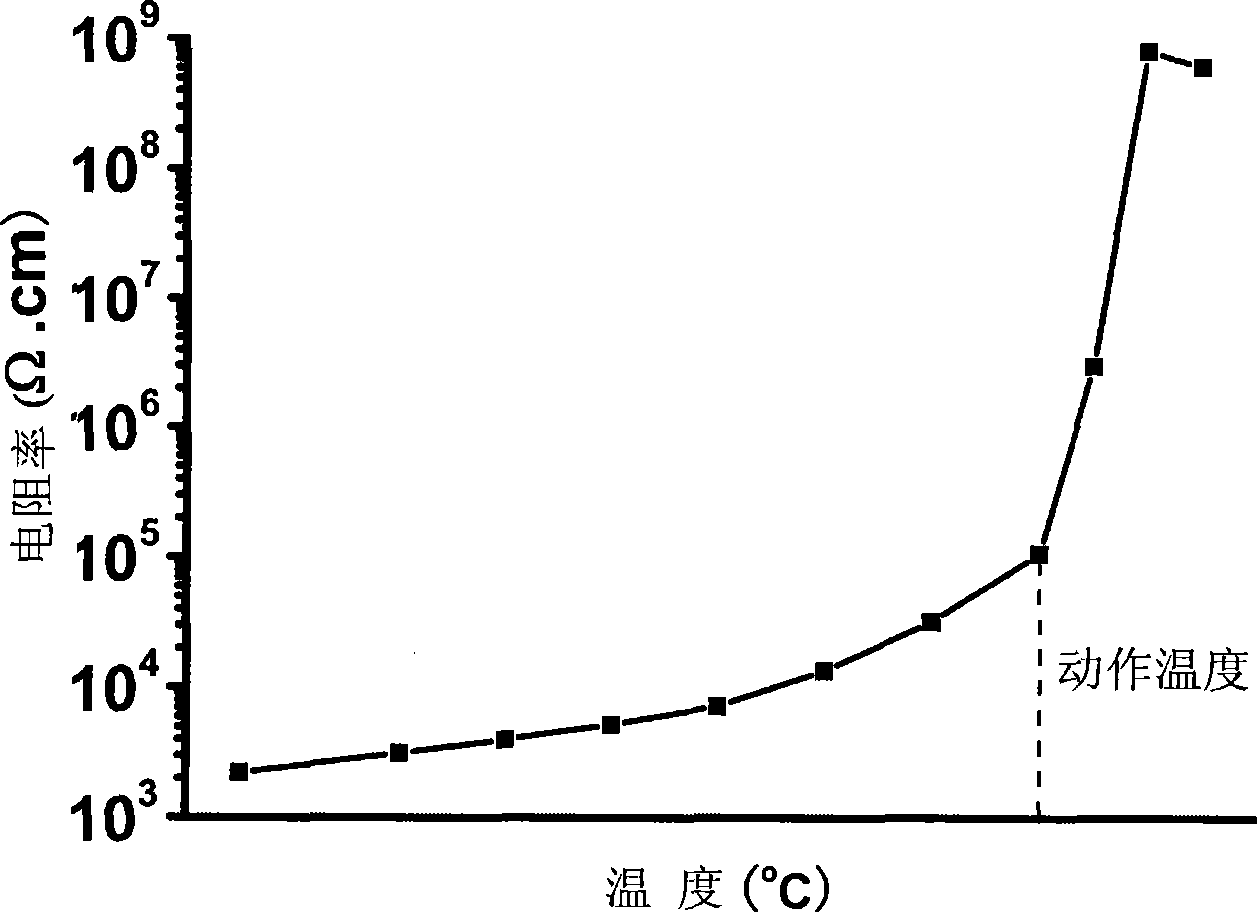

[0040] Embodiment 1, 100 parts by weight of ethylene-vinyl acetate, 15 parts by weight of paraffin, 15 parts by weight of furnace carbon black and 5 parts by weight of conductive carbon black are mixed in an internal mixer at 140 ° C and molded, and the mixture is formed at 70 ° C. Keep warm for 20 hours, cool to room temperature, use 60 Co-γ-ray irradiation crosslinking, irradiation dose 20kGy, temperature-resistance characteristics measurement, the room temperature resistivity is 8.9×10 3 Ω·cm, resistivity before operating temperature is 1.1×10 5 Ω cm, peak resistivity 1.5×10 9 Ω·cm.

Embodiment 2

[0041] Embodiment two, 100 parts by weight of low density polyethylene, 10 parts by weight of microcrystalline wax, 25 parts by weight of acetylene carbon black and 5 parts by weight of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) Oxygen) hexane, mixed at 160°C in a twin-screw extruder, then molded, kept at 140°C for 10 hours, cooled to room temperature, and then chemically crosslinked, and the temperature-resistance characteristics were measured. The room temperature resistivity was 3.8× 10 3 Ω·cm, resistivity before operating temperature is 5.2×10 4 , with a peak resistivity of 6.6×10 9 Ω·cm.

Embodiment 3

[0042]Embodiment three, with 100 parts by weight of low-density polyethylene, 20 parts by weight of polyethylene wax, 15 parts by weight of acetylene black, 5 parts by weight of multi-walled carbon nanotubes and 0.01 parts by weight of dicumyl peroxide, After mixing in an internal mixer at 160°C, it was formed and chemically cross-linked, and the temperature-resistance characteristics were measured. The room temperature resistivity was 6.9×10 3 Ω·cm, resistivity before operating temperature is 8.2×10 4 , with a peak resistivity of 9.3×10 8 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com