Method for preparing proton conductive film fuel cell by spin-coating process

A proton conductive membrane, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of proton conductors hindering application, large internal resistance of proton conductors, etc., to achieve small grains, uniform composition and structure, Beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

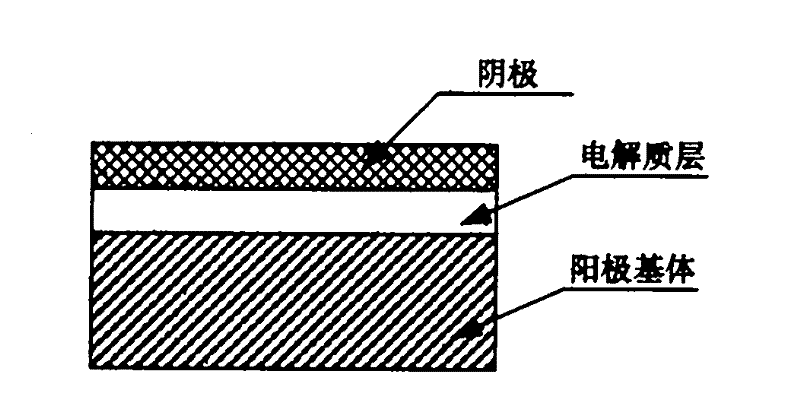

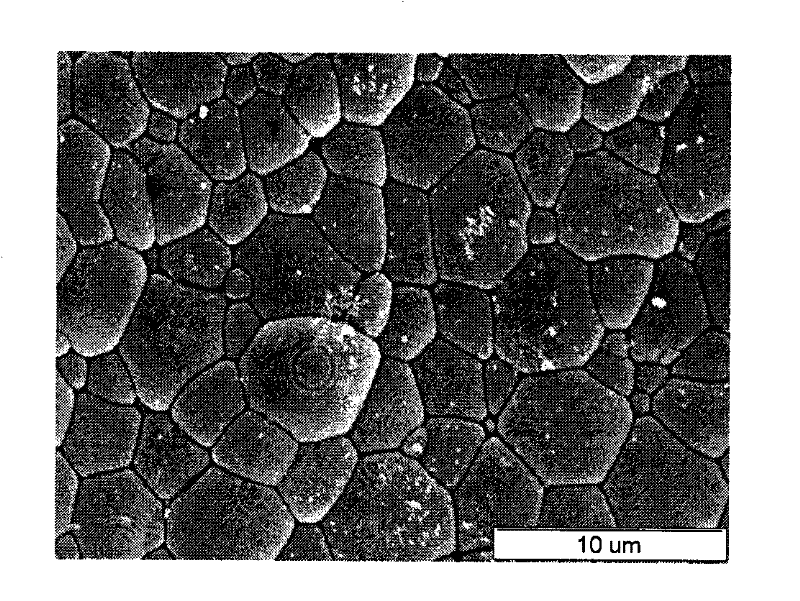

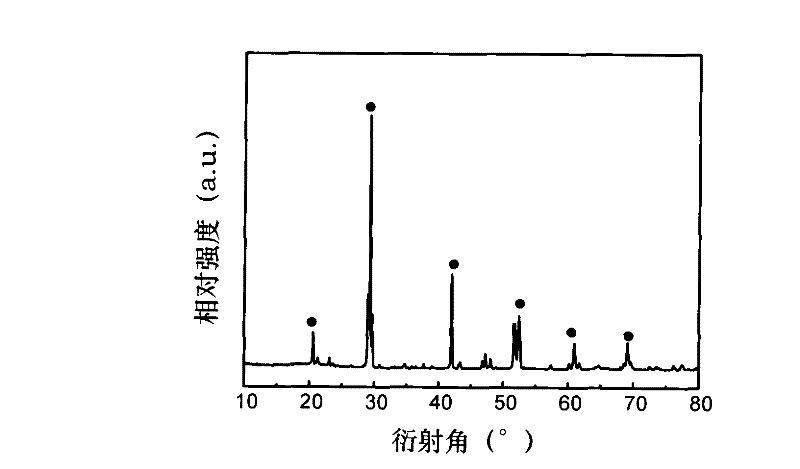

[0056] The present invention is a kind of adopting spin coating method to prepare SrCe 0.95 Y 0.05 o 2.975 A method for a proton-conducting membrane fuel cell, comprising the following steps:

[0057] Step 1: Make the mixed powder

[0058] Strontium carbonate SrCO 3 , cerium oxide CeO 2 and yttrium oxide Y 2 o 3 Put it into a ball mill and mill it for 5 hours to obtain a mixed powder with a particle size of 30-60 μm;

[0059] Dosage: 100g of mixed powder contains 46.6g of strontium carbonate SrCO 3 , 51.6g of cerium oxide CeO 2 and 1.8 g of yttrium oxide Y 2 o 3 ;

[0060] Step 2: Prepare raw material powder

[0061] Treat the mixed powder prepared in step 1 at a drying temperature of 100° C. for 15 hours to obtain raw material powder;

[0062] Step 3: Preparation of SrCe 0.95 Y 0.05 o 2.975 powder

[0063] The mixed powder prepared in step 1 was kept at a sintering temperature of 1200°C for 10 hours to obtain a precursor powder;

[0064] Step 4: Fabricate th...

Embodiment 2

[0080] The present invention is a kind of adopting spin coating method to prepare SrCe 0.9 Y 0.1 o 2.95 A method for a proton-conducting membrane fuel cell, comprising the following steps:

[0081] Step 1: Make the mixed powder

[0082] Strontium carbonate SrCO 3 , cerium oxide CeO 2 and yttrium oxide Y 2 o 3 Put it into a ball mill and mill it for 10 hours to obtain a mixed powder with a particle size of 30-60 μm;

[0083] Dosage: 100g of mixed powder contains 47.0g of strontium carbonate SrCO 3 , 49.3g of cerium oxide CeO 2 and 3.7 g of yttrium oxide Y 2 o 3 ;

[0084] Step 2: Prepare raw material powder

[0085] Treat the mixed powder prepared in step 1 at a drying temperature of 120° C. for 10 hours to obtain raw material powder;

[0086] Step 3: Preparation of SrCe 0.9 Y 0.1 o 2.95 powder

[0087] The mixed powder prepared in step 1 was kept at a sintering temperature of 1400°C for 6 hours to obtain a precursor powder;

[0088] Step 4: Fabricate the fuel...

Embodiment 3

[0105] The present invention is a kind of adopting spin coating method to prepare SrCe 0.8 Y 0.2 o 2.9 A method for a proton-conducting membrane fuel cell, comprising the following steps:

[0106] Step 1: Make the mixed powder

[0107] Strontium carbonate SrCO 3 , cerium oxide CeO 2 and yttrium oxide Y 2 o 3 Put it into a ball mill and mill it for 3 to 12 hours to obtain a mixed powder with a particle size of 30 to 60 μm;

[0108] Dosage: 100g of mixed powder contains 47.9g of strontium carbonate SrCO 3 , 44.8g of cerium oxide CeO 2 and 7.3 g of yttrium oxide Y 2 o 3 ;

[0109] Step 2: Prepare raw material powder

[0110] Treat the mixed powder prepared in step 1 at a drying temperature of 150° C. for 10 hours to obtain raw material powder;

[0111] Step 3: Preparation of SrCe 0.8 Y 0.2 o 2.9 Powder

[0112] The mixed powder prepared in step 1 was kept at a sintering temperature of 1300°C for 10 hours to obtain a precursor powder;

[0113] Step 4: Fabricate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com