Method for preparing chlorinated diphenyl ether

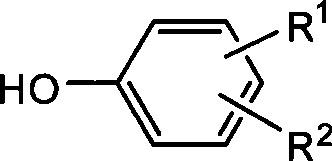

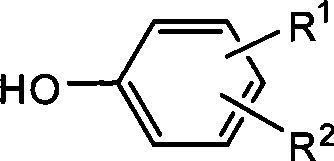

A technology of chlorinated diphenyl ether and diphenyl ether, which is applied in the field of preparation of chlorinated or polychlorinated diphenyl ethers, can solve the problems of many by-products and high reaction temperature, and achieves the advantages of accelerated reaction speed and high product yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

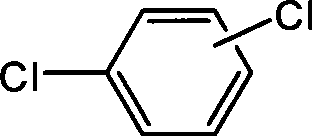

[0046] Preparation of 4-chloro-diphenyl ether

[0047] Add 94g of phenol, 650g of p-dichlorobenzene, 1g of cuprous chloride with an average particle size of 600nm, 0.5g of potassium iodide, 150g of dimethylacetamide and 50mL of xylene into a four-necked flask, and add 40g of sodium hydroxide to it while stirring , and then gradually increase the temperature until the inner temperature reaches 120°C and starts to azeotrope, and the dehydration is completed when the inner temperature reaches 160°C, then continue to stir and react at 160-165°C for 12 hours, stop heating, let stand to cool, and filter. The filtrate was distilled under reduced pressure, and the fraction at 135-138° C. / 6 mmHg was collected to obtain 164.8 g of a colorless transparent liquid. The yield of 4-chloro-diphenyl ether (calculated as phenol) is 80.6%, and the content is 99.3% through gas chromatography analysis.

Embodiment 2

[0049] Preparation of 3-chlorodiphenyl ether

[0050] Add 94g of phenol, 650g of m-dichlorobenzene, 2.5g of cuprous chloride with an average particle size of 600nm, potassium carbonate, 150g of dimethylacetamide and 50mL of xylene into a four-necked bottle, and gradually heat up to an internal temperature of 140°C. Azeotrope, then slowly raise the temperature to 160-165°C and continue stirring for 12 hours, stop heating, let stand to cool, and filter. The filtrate was distilled under reduced pressure, and the fraction at 128-132°C / 5mmHg was collected to obtain 175.3 g of a colorless transparent liquid. The yield of 3-chloro-diphenyl ether (calculated as phenol) is 85.7%, and the content is 99.5% through gas chromatography analysis.

Embodiment 3

[0052] Preparation of 3,4'-dichlorodiphenyl ether

[0053] Add 130g of p-chlorophenol, 600g of m-dichlorobenzene and 100mL of toluene into a four-neck flask, add 41g of sodium hydroxide to it, and perform azeotropic dehydration at 120-140°C. During the dehydration process, most of 65mL of toluene will be co-distilled, and then add 1.5g of cuprous chloride with an average particle size of 600nm and 60g of diethylene glycol diethyl ether were heated up to 170°C, and the reaction was continued with stirring at 170°C for 20h. Cool to room temperature after the reaction, filter and distill the filtrate under reduced pressure, collect the fraction at 146°C / 5mmHg to obtain 219g of a colorless transparent liquid. The yield of 3,4'-dichlorodiphenyl ether (in terms of p-chlorophenol) is 90.6%, and through gas chromatography analysis, the content is 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com