Connecting method for TiNi shape memory alloy and stainless steel dissimilar material

A technology of memory alloys and dissimilar materials, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high cost and high joint strength, and achieve the effect of improving joint strength, good connection, and reducing joint crack sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

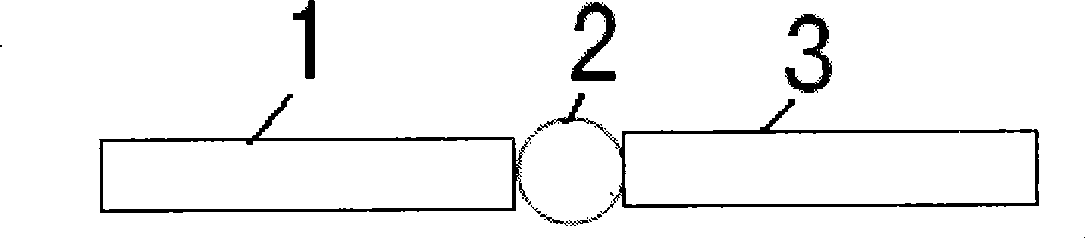

Image

Examples

Embodiment 1

[0016] Nickel wire is used as filling material, inert gas protection, and low-power pulsed laser is used as heat source to weld TiNi shape memory alloy sheet and stainless steel sheet. TiNi shape memory alloy should be cleaned before welding, and the front and back of the welded joint need to be Argon is used for protection, and the back of the welded joint needs to be covered with a copper plate. The thickness of the material to be welded is 0.1mm. Degrease with acetone first, then soak the TiNi shape memory alloy in a mixed solution of hydrofluoric acid, nitric acid and water with a volume ratio of 2:1:5 for 15 minutes, and then rinse with water , Dry naturally. The nickel wire contains more than 99% Ni in mass percentage and has a diameter of 0.15mm. The nickel wire is preset between the TiNi shape memory alloy to be welded and the stainless steel before welding, and the misalignment during assembly cannot exceed 10% of the thickness of the material to be welded. The iner...

Embodiment 2

[0018] Nickel wire is used as filling material, inert gas protection, and low-power pulsed laser is used as heat source to weld TiNi shape memory alloy sheet and stainless steel sheet. TiNi shape memory alloy should be cleaned before welding, and the front and back of the welded joint need to be Argon is used for protection, and the back of the welded joint needs to be covered with a copper plate. The thickness of the material to be welded is 0.5mm. Degrease with acetone first, then soak the TiNi shape memory alloy in a mixed solution of hydrofluoric acid, nitric acid and water with a volume ratio of 2:1:5 for 15 minutes, and then rinse with water , Dry naturally. The nickel wire contains more than 99% Ni in mass percentage and has a diameter of 0.15 mm. The nickel wire is preset between the TiNi shape memory alloy to be welded and the stainless steel before welding, and the misalignment during assembly cannot exceed 10% of the thickness of the material to be welded. The ine...

Embodiment 3

[0020] Nickel wire is used as filling material, inert gas protection, and low-power pulsed laser is used as heat source to weld TiNi shape memory alloy sheet and stainless steel sheet. TiNi shape memory alloy should be cleaned before welding, and the front and back of the welded joint need to be Argon is used for protection, and the back of the welded joint needs to be covered with a copper plate. The thickness of the material to be welded is 0.2mm. Degrease with acetone first, then soak the TiNi shape memory alloy in a mixed solution of hydrofluoric acid, nitric acid and water with a volume ratio of 2:1:5 for 15 minutes, and then rinse with water , Dry naturally. The nickel wire contains more than 99% Ni in mass percentage and has a diameter of 0.3 mm. The nickel wire is preset between the TiNi shape memory alloy to be welded and the stainless steel before welding, and the misalignment during assembly cannot exceed 10% of the thickness of the material to be welded. The iner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com