Method for preparing carbon material and polyimide compounded sandwich film

A polyimide and film preparation technology, which is applied in the field of sandwich film preparation, can solve the problems of increased loss, poor mechanical properties of composite materials, and high preparation costs, and achieve reduced dielectric loss, excellent heat resistance, and good film-forming performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

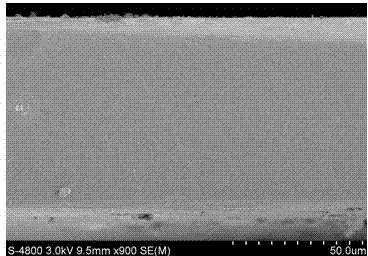

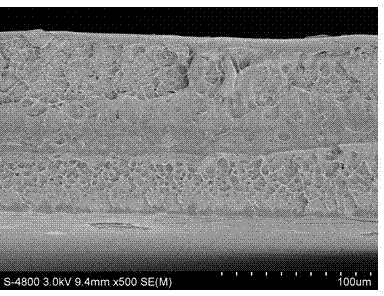

Embodiment 1

[0022] Add carbon fiber to N,N-dimethylacetamide that can dissolve polyamic acid to form a 5% (wt / wt) suspension, stir at room temperature for 5 hours, take out 10 ml, and add 0.5 g 4,4'-diaminodiphenyl ether and 0.509g pyromellitic dianhydride were stirred at room temperature for 12h to polymerize. Take another 20ml of N,N-dimethylacetamide, add 0.5g of 4,4'-diaminodiphenyl ether and 0.509g of pyromellitic dianhydride, and stir at room temperature for 12h to polymerize. Inject 10ml of polyamic acid solution into the substrate (the amount of solution can be added to adjust the thickness of the film), put it in a vacuum drying oven and heat it to 90°C for 2 hours to remove the solvent and form a polyamic acid film. Keep the vacuum and lower the temperature to 70°C, pour 10ml of carbon fiber and polyamic acid mixed solution on the polyamic acid film, heat to 90°C, and remove the solvent for 2 hours under vacuum to form the second layer of film. Keep the vacuum and lower the tem...

Embodiment 2

[0024] In Example 1, the 4,4′-diaminodiphenyl ether was changed to 9,9-bis[4-(4-aminophenoxy)phenyl]fluorene, and other conditions remained unchanged. The maximum dielectric constant of the obtained material is 45, the maximum dielectric loss is 0.015, and the 5% degradation temperature of the film is 540°C.

Embodiment 3

[0026] The amount of carbon fiber N,N-dimethylacetamide mixed solution added in Example 1 was increased to 5ml, and other conditions remained unchanged. The maximum dielectric constant of the obtained material is 20, the maximum dielectric loss is 0.005, and the 5% degradation temperature of the film is 571°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com