Production method of Zintl phase monocrystal

A technology of Zinter phase and single crystal, applied in the field of Zinter phase single crystal thermoelectric material and its preparation, can solve the problems of uneconomical, high energy consumption and high reaction temperature, and achieve the effect of low energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

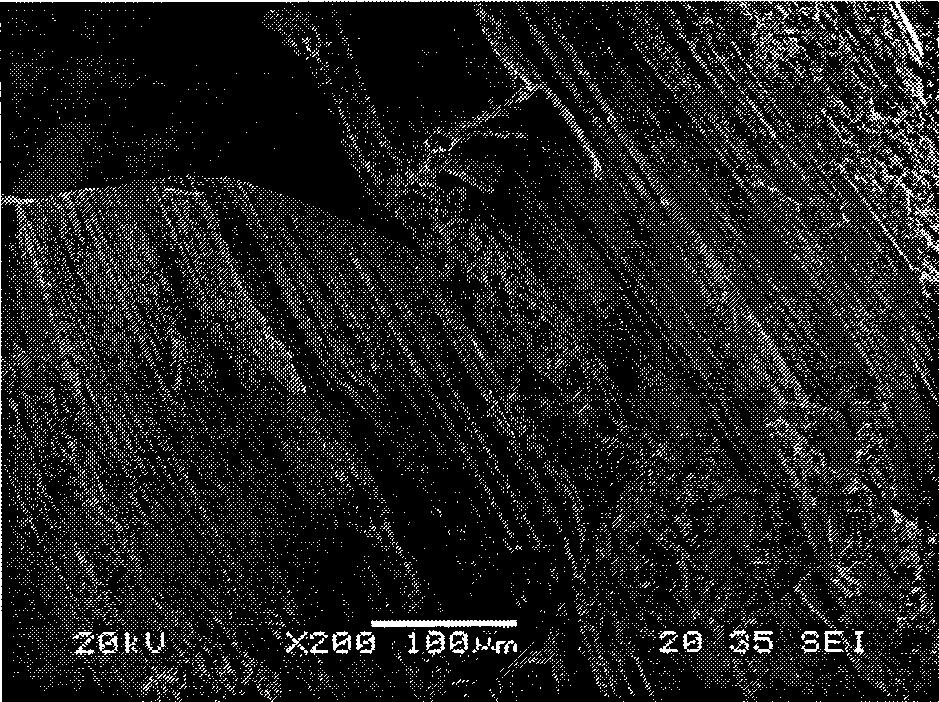

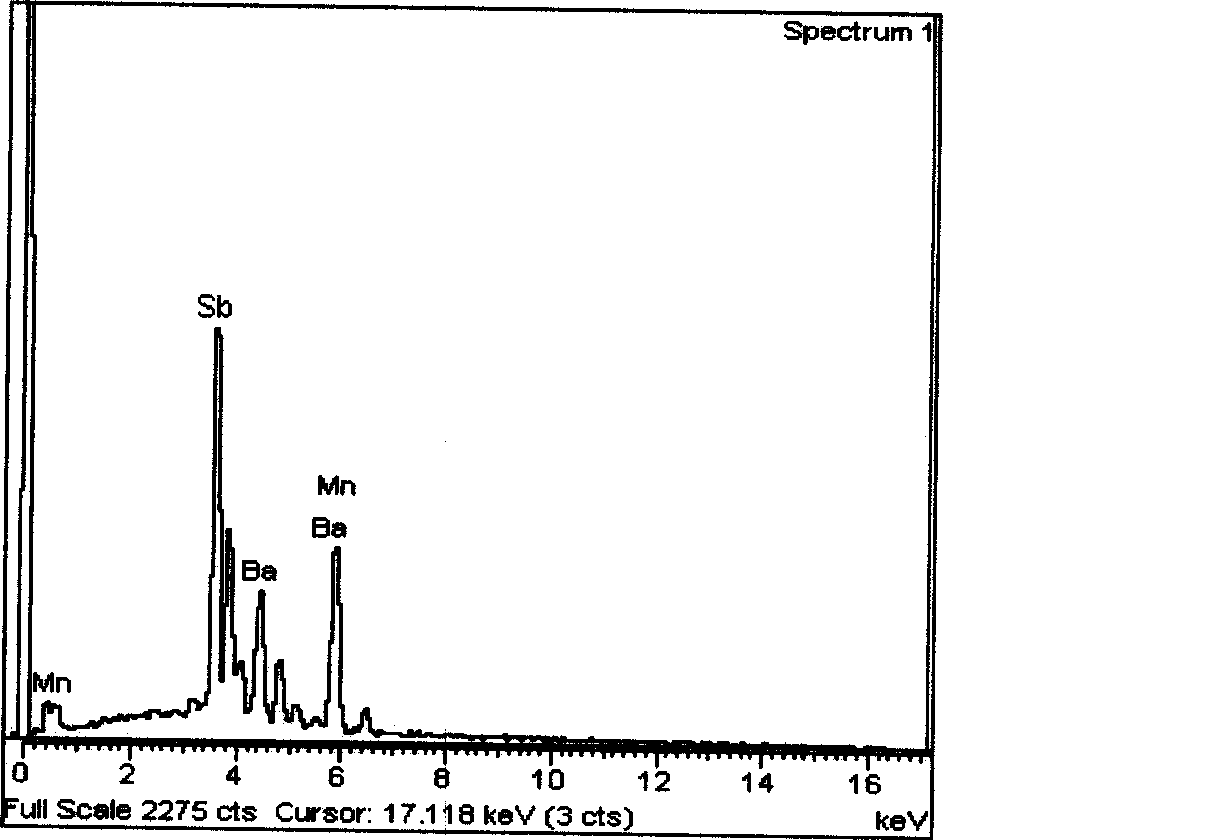

Embodiment 1

[0031] Weigh 0.7g of high-purity elemental barium, 0.56g of manganese, 1.241g of antimony and 8.672g of tin in an argon-protected glove box according to Ba:Mn:Sb:Sn=1:2:2:14.3 (molar ratio). After weighing, put it in a corundum crucible with a volume of 5ml, cover a small amount of quartz wool, cover the above crucible with the same corundum crucible, then place it in a quartz tube, seal it with plastic wrap, remove it from the glove box, and vacuum it And wash several times with argon. The quartz tube was sealed under 1 / 5 atm argon protection. Finally, place the quartz tube in a muffle furnace, heat up to 1100 °C at a rate of 600 °C / h, and slowly cool down (2 °C / h) to 750 °C after 1 hour of heat preservation, then quickly take out the quartz tube and use a centrifuge (4000r / min speed) centrifugation. After the temperature dropped to room temperature, the quartz tube was put into an argon glove box and crushed, and the obtained product was washed with 0.1M hydrochloric acid...

Embodiment 2

[0035] Weigh 0.538g of high-purity elemental barium, 0.114g of strontium, 0.574g of manganese, 0.574g of manganese, and 1.273g and tin 8.873g. After weighing, put it in a corundum crucible with a volume of 5ml, cover a small amount of quartz wool, cover the above crucible with the same corundum crucible, then place it in a quartz tube, seal it with plastic wrap, remove it from the glove box, and vacuum it And wash several times with argon. The quartz tube was sealed under 1 / 5 atm argon protection. Finally, place the quartz tube in a muffle furnace, heat up to 1100 °C at a rate of 600 °C / h, and slowly cool down (2 °C / h) to 750 °C after 1 hour of heat preservation, then quickly take out the quartz tube and use a centrifuge (4000r / min speed) centrifugation. After the temperature dropped to room temperature, the quartz tube was put into an argon glove box and crushed, and the obtained product was washed with 0.1M hydrochloric acid to remove remaining tin to obtain Ba 0.75 Sr ...

Embodiment 3

[0039] Weigh high-purity elemental barium 0.479g, yttrium 0.259g, manganese 0.548g, antimony 1.214g and tin 8.463g. After weighing, put it in a corundum crucible with a volume of 5ml, cover a small amount of quartz wool, cover the above crucible with the same corundum crucible, then place it in a quartz tube, seal it with plastic wrap, remove it from the glove box, and vacuum it And wash several times with argon. The quartz tube was sealed under 1 / 5 atm argon protection. Finally, place the quartz tube in a muffle furnace, heat up to 1100 °C at a rate of 600 °C / h, and slowly cool down (2 °C / h) to 750 °C after 1 hour of heat preservation, then quickly take out the quartz tube and use a centrifuge (4000r / min speed) centrifugation. After the temperature dropped to room temperature, the quartz tube was put into an argon glove box and crushed, and the obtained product was washed with 0.1M hydrochloric acid to remove remaining tin to obtain Ba 0.7 Yb 0.3 mn 2 Sb 2 single crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com