Production method of carbamido thickening agent for lubricating grease

A production method and thickener technology, which are applied in thickeners, lubricating compositions, petroleum industry, etc., can solve the problems of inability to filter, reduce the use effect, workers' health and safety, etc., achieve convenient transportation and storage, lower threshold and cost, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

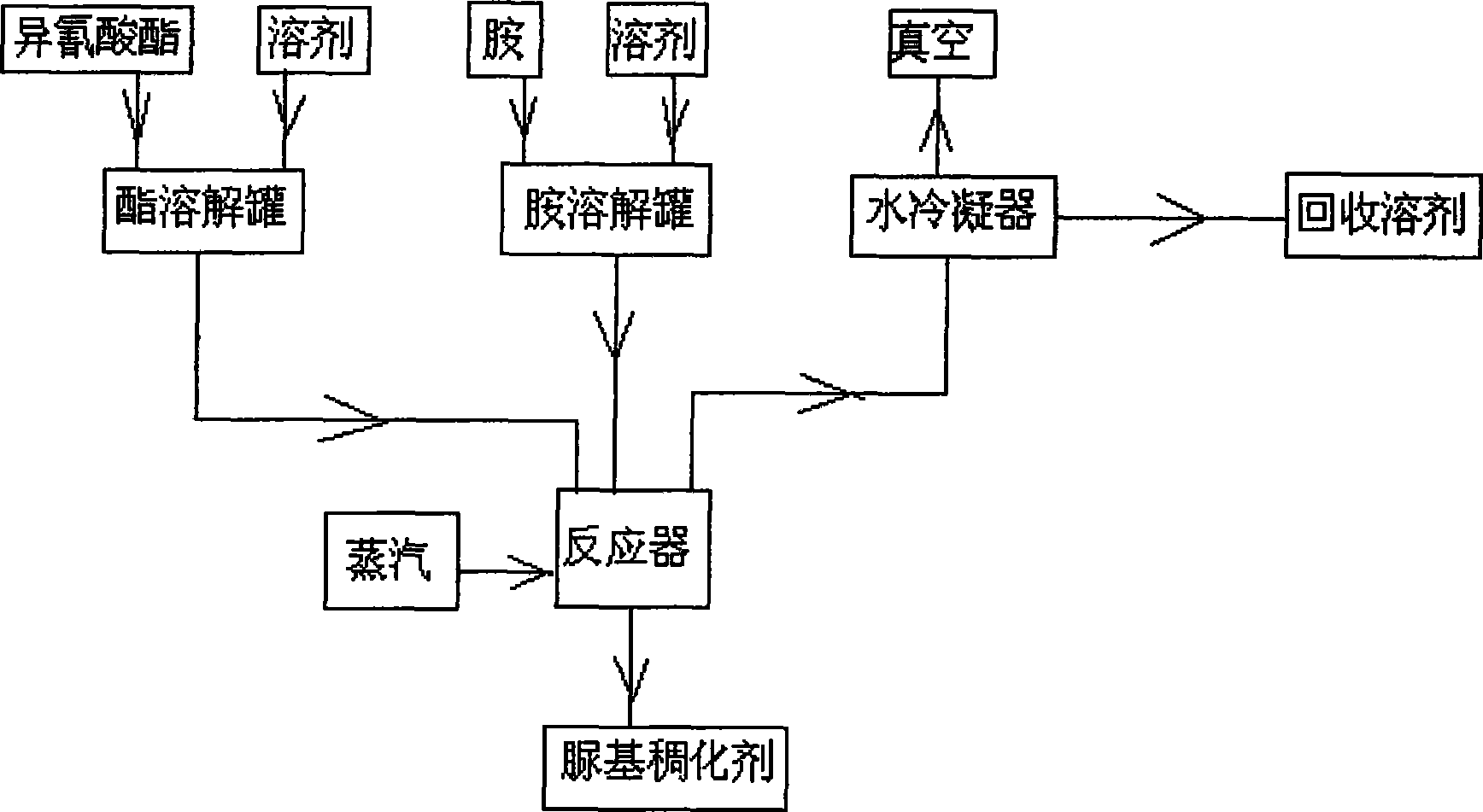

Method used

Image

Examples

Embodiment 1

[0017] Two 100L tanks (namely, the ester dissolving tank and the amine dissolving tank of the present invention) and a 250L reactor (also called reaction tank) are purged with nitrogen. Add 50kg of dioxane and 8.17kg of 4,4'-diphenylmethane diisocyanate into the 100L ester dissolving tank, stir, heat to 50℃ to dissolve, and set aside; add 50kg of dioxane into the 100L amine dissolving tank , Octadecylamine 8.67kg, cyclohexylamine 3.17kg, stirring, heating to 50 ℃ to dissolve, and then pump into the 250L reactor. The reactor is stirred, heated, and the temperature is controlled at 60°C. Then, within 1 hour, the 4,4'-diphenylmethane diisocyanate solution that has been dissolved and prepared before is uniformly pumped from the ester dissolving tank; 4,4'-diphenyl After adding the methyl methane diisocyanate solution, continue the equilibrium reaction and dispersion at 60°C—70°C for 1 hour; then, the reactor is evacuated, and the dioxane solvent is recovered through the condensation s...

Embodiment 2

[0019] Two 100L tanks and one 250L reactor were purged with nitrogen. Add 50kg of N,N-dimethylformamide into a 250L kettle; add 7.14kg of 4,4'-diphenylmethane diisocyanate into a 100L ester dissolving tank, heat to 80°C to melt, and set aside. Add 50kg of N,N-dimethylformamide, 11.53kg of octadecylamine, and 1.33kg of aniline into the 100L amine dissolving tank, stir, heat to 60℃ to dissolve, and then pump into the 250L reactor. The reactor is stirred, heated, and the temperature is controlled at 80°C, and then within 1 hour, the previously melted 4,4'-diphenylmethane diisocyanate; 4,4'-diphenyl is uniformly pumped from the ester dissolving tank After the addition of methane diisocyanate, continue the equilibrium reaction and dispersion at 80℃-100℃ for 1 hour; then, the reactor is evacuated and the N,N-dimethylformamide solvent is recovered through the condensation recovery system. The initial vacuum is -0.05Mpa (Table), the final vacuum degree is <-0.095Mpa (table), and the final...

Embodiment 3

[0021] Two 100L tanks and one 250L reactor were purged with nitrogen. Add 50 kg of ethyl acetate and 8.95 kg of 2,4-toluene diisocyanate into a 100L ester dissolving tank, stir, dissolve, and heat to 50°C for use. Add 50kg of ethyl acetate, 9.44kg of p-toluidine and 1.6kg of p-chloroaniline into the 100L amine dissolving tank, stir, heat to 50°C to dissolve, and then pump into the 250L reactor. The reactor is stirred, heated, and the temperature is controlled at 60°C. Then, within 1 hour, the 2,4-toluene diisocyanate solution that has been dissolved and prepared before is uniformly pumped from the ester dissolving tank; after the 2,4-toluene diisocyanate solution is added , Continue to equilibrate the reaction and disperse at 60℃—70℃ for 1 hour; then, the reactor is evacuated, the ethyl acetate solvent is recovered through the condensation recovery system, and the vacuum degree is gradually increased, and the final vacuum degree is <-0.095Mpa (table), and the material is finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com