Diffusion layer for integral regeneratable fuel cell and preparation thereof

A fuel cell and diffusion layer technology, which is applied in the direction of regenerative fuel cells, fuel cell parts, fuel cells, etc., can solve the problems of intermetallic compound URFC diffusion layer raw materials, etc., achieve superior electrical conductivity, improve cycle life, The effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

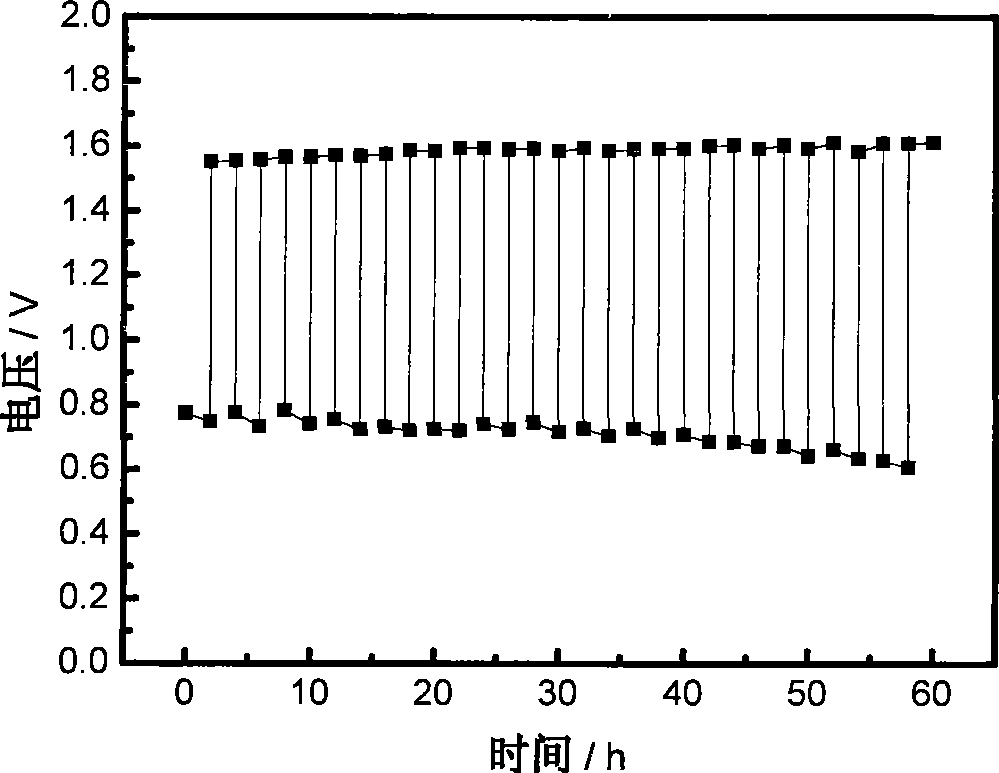

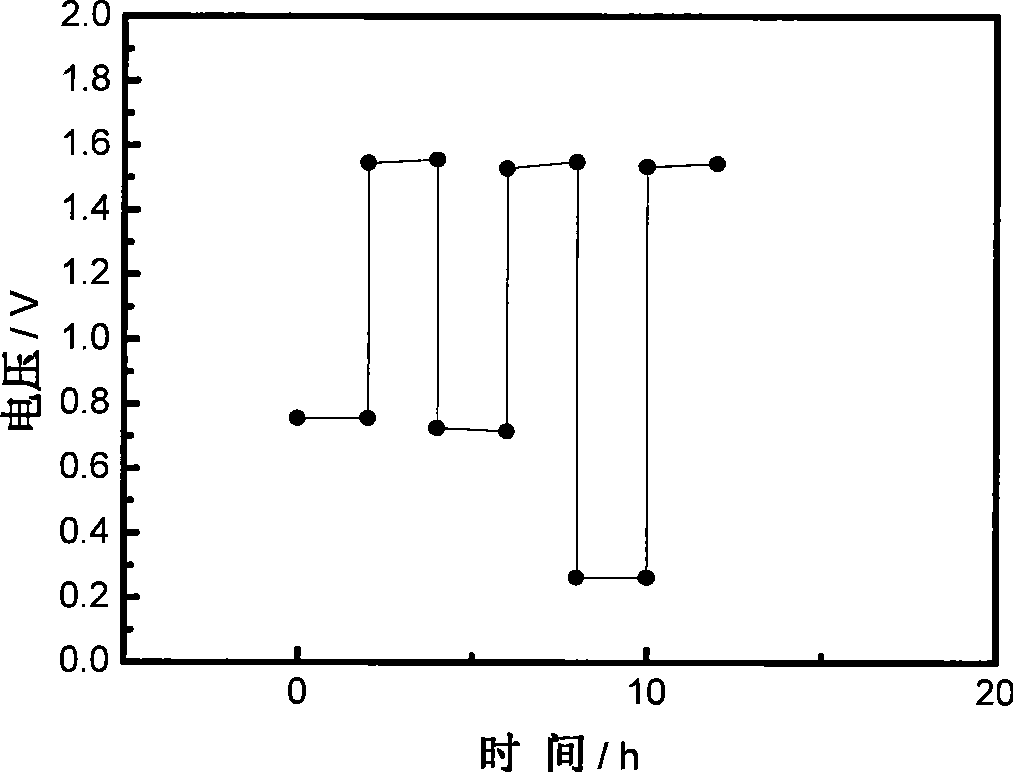

Examples

Embodiment 1

[0041] Take 100 mg of TiC powder with a particle size of 8 nanometers and add it to 10 ml of 2 mol / L hydrochloric acid solution, ultrasonically treat it for 15 minutes, filter and dry to obtain 90 mg of relatively pure TiC powder.

[0042] Mix 80 mg of the obtained TiC powder with Ir with a particle size of 10 nm at a mass ratio of 4:1, add 90 g of the mixture to 10 ml of isopropanol, add 10 mg of PTFE, and ultrasonically treat the mixture to obtain a viscous liquid . The viscous solution is evenly coated on 7wt% PTFE, porosity 60%, thickness 190 microns, area 20cm 2 The carbon paper was sintered at 260° C. for 30 minutes, sintered at 360° C. for 30 minutes, and naturally cooled to obtain the anode diffusion layer with a thickness of 220 microns and a porosity of 50% according to the present invention.

[0043] Preparation of integrated renewable fuel cell core chip MEA: fully disperse and mix catalyst, Nafion solution and 5ml isopropanol solution in ultrasonic wave to obtain...

Embodiment 2

[0055] Take 100 mg of ZrN powder with a particle size of 50 nanometers and add it to 40 ml of 1 mol / L hydrochloric acid solution, ultrasonicate for 60 minutes, filter and dry to obtain 95 mg of relatively pure ZrN powder.

[0056] Get the obtained ZrN powder 90mg, particle diameter is the IrO of 40nm 2 / TiN5mg, IrO with a particle size of 20nm 2 Mix 5 mg, add 40 g of the mixture to 10 ml of ethylene glycol, add 60 mg of PTFE, and ultrasonicate the mixture to obtain a viscous liquid. Apply the viscous solution evenly on the surface containing 35wt% PTFE, with a porosity of 40%, a thickness of 400 microns, and an area of 20 cm 2 The carbon paper was sintered at 270° C. for 80 minutes, and then sintered at 370° C. for 80 minutes. After natural cooling, the anode diffusion layer with a thickness of 425 microns and a porosity of 30% according to the present invention was obtained.

[0057] Single cell assembly and testing The operating conditions of the single cell are the same...

Embodiment 3

[0059] Take 100 mg of (TiAl)(CN) powder with a particle size of 80 nm and add it to 20 ml of 1 mol / L hydrochloric acid solution, ultrasonicate for 30 minutes, filter and dry to obtain 90 mg of relatively pure (TiAl)(CN) powder.

[0060] Get 50 mg of the obtained (TiAl) (CN) powder and mix it with IrRu / Ti with a particle size of 90 nm according to the mass ratio of 1:1. Put 30 g of the mixture into 1 ml of propanol and 3 mL of ethanol, then add 20 mg of PTFE, and ultrasonically treat it. Mix well to obtain a viscous liquid. Evenly scrape the viscous solution on the surface containing 20wt% PTFE, with a porosity of 65%, a thickness of 280 microns, and an area of 20 cm 2 The titanium fibers were sintered at 260°C for 60 minutes, sintered at 360°C for 60 minutes, and cooled naturally to obtain the anode diffusion layer with a thickness of 310 microns and a porosity of 50% according to the present invention.

[0061] The preparation of the integrated renewable fuel cell core chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com