Method for purifying 2, 2-dimethyl-cyclopropane carboxamide produced by biocatalytic method

A technology of dimethylcyclopropane carboxamide, biocatalysis method, applied in microorganism-based methods, biochemical equipment and methods, carboxylic acid amide separation/purification, etc., can solve the problem of difficult to meet industrial production, product recovery rate and purity Low problems, to achieve the effect of simple and easy production process, high product recovery rate and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Inoculate the Delftia tsuruhalensis CCTCC No.M 205115 activated by the slant into a 1L Erlenmeyer flask containing 200ml of seed medium, and prepare the seed medium per 1000mL as follows: mannitol 10.0g, yeast extract 5.0g, peptone 2.0 g, NaCl1.0g, K 2 HPO 4 1.0g, KH 2 PO 4 1.0g, MgSO 4 0.2g, FeSO4 0.01g, CaCl 2 0.05g, made up to 1000mL with water, natural pH (121°C, sterilized for 20min), cultured at 0°C for 20h, to obtain seed liquid.

[0020] The above seed solution was inoculated into a 5L fermenter filled with 70% fermentation medium. The fermentation medium is prepared as follows per 1000mL: glucose 10.0g, yeast extract 5.0g, peptone 2.0g, NaCl 1.0g, K 2 HPO 4 1.0g, KH 2 PO 4 1.0g, MgSO 4 0.2g, FeSO 4 0.01g, CaCl 20.05g, caprolactam 1.0g, make up to 1000mL with water, pH7.0 (sterilized by solid tank). Under the conditions of aeration rate of 1:0.5 (ratio of the volume of the culture solution to the volume of air introduced per minute), stirring...

Embodiment 2

[0023] Inoculate the strain Rhodococcus equi CCTCC No.M 205114 activated on the slant into a 1L Erlenmeyer flask containing 200ml of seed medium, and prepare the seed medium per 1000mL as follows: glucose 14.0g, yeast extract 5.0g, NaCl 1.0g , K 2 HPO 4 1.0g, KH 2 PO 4 1.0g, MgSO 4 0.2g, FeSO4 0.01g, CoCl 2 0.01g, CaCl 2 0.05g, made up to 1000mL with distilled water, natural pH (121°C, sterilized for 20min), cultured at 30°C for 2 days to obtain seed liquid.

[0024] Inoculate the above seed solution into a 10L fermenter with 5L of fermentation medium, and prepare the following composition per 1000mL of fermentation medium: glucose 20.0g, yeast extract 5.0g, urea 6.0g, NaCl 1.0g, K 2 HPO 4 1.0g, KH 2 PO 4 1.0g, MgSO 4 0.2g, FeSO4 0.01g, CoCl 2 0.01g, CaCl 2 0.05g, caprolactam 3.0g, distilled water to make up to 1000mL, pH natural (solid tank sterilization). Cultivate for 60 hours at a ventilation rate of 1:0.8, a stirring speed of 280 rpm, a tank pressur...

Embodiment 3

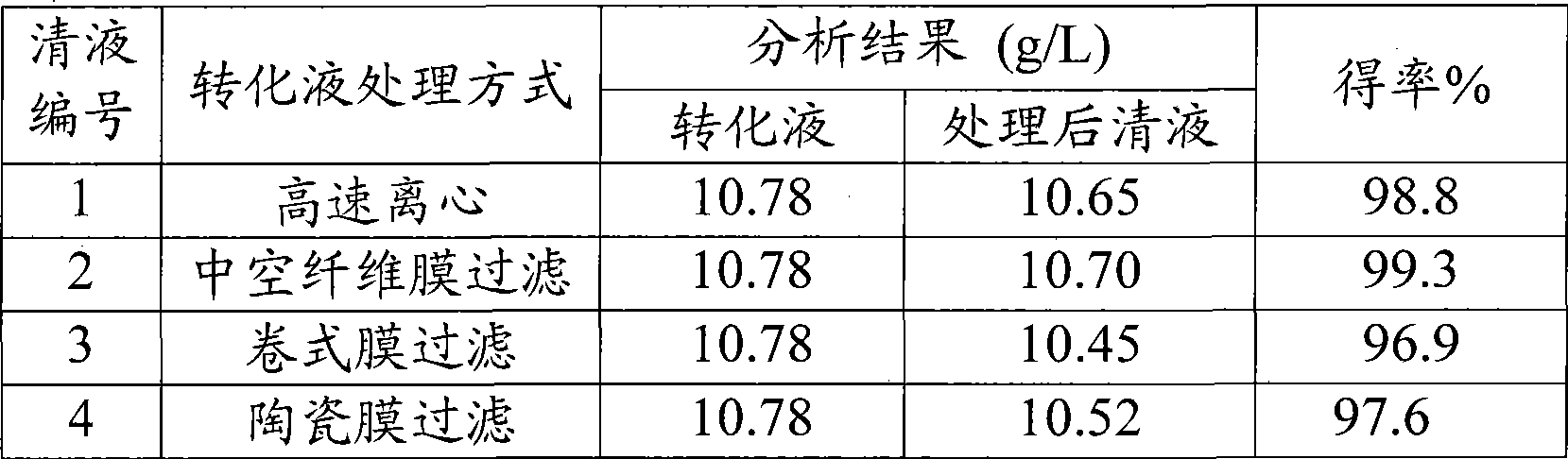

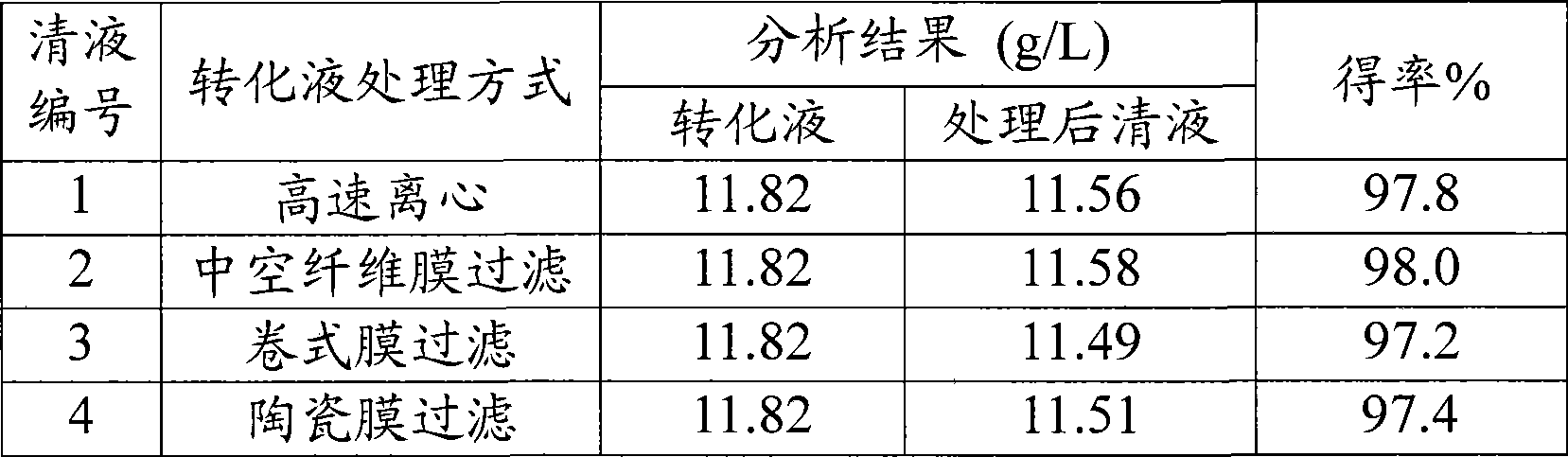

[0027] Each get 0.5L of the conversion liquid obtained in Example 1 or 2, and process it in the following solid-liquid separation mode:

[0028] 1. High-speed centrifugation, at 20°C, 12000rpm for 10min;

[0029] 2. Hollow fiber membrane filtration, flow rate 100ml min -1 , pressure 0.8Kg / cm 2 ;

[0030] 3. Roll membrane filtration, flow rate 100ml min -1 , pressure 10Kg / cm 2 ;

[0031] 4. Ceramic membrane filtration, flow rate 100ml min -1 , pressure 4Kg / cm 2 ;

[0032] Collect and obtain filtrate supernatant, gas chromatographic analysis, the result is listed in Table 1.

[0033] Table 1: Example 1 Filtration Clear Liquid Gas Chromatography Analysis Results

[0034]

[0035] Table 2: Example 2 Filtration Clear Liquid Gas Chromatography Analysis Results

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com