Comprehensive recovery method of gold ore resource containing molybdenum multi-metal

A recovery method and multi-metal technology, which are applied in the directions of flotation, solid separation, and process efficiency improvement, can solve the problems of difficulty in achieving expected results, low metal separation grade, and difficulty in drug selection, and reduce the impact of wastewater on the environment. Pollution, high degree of automation, low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

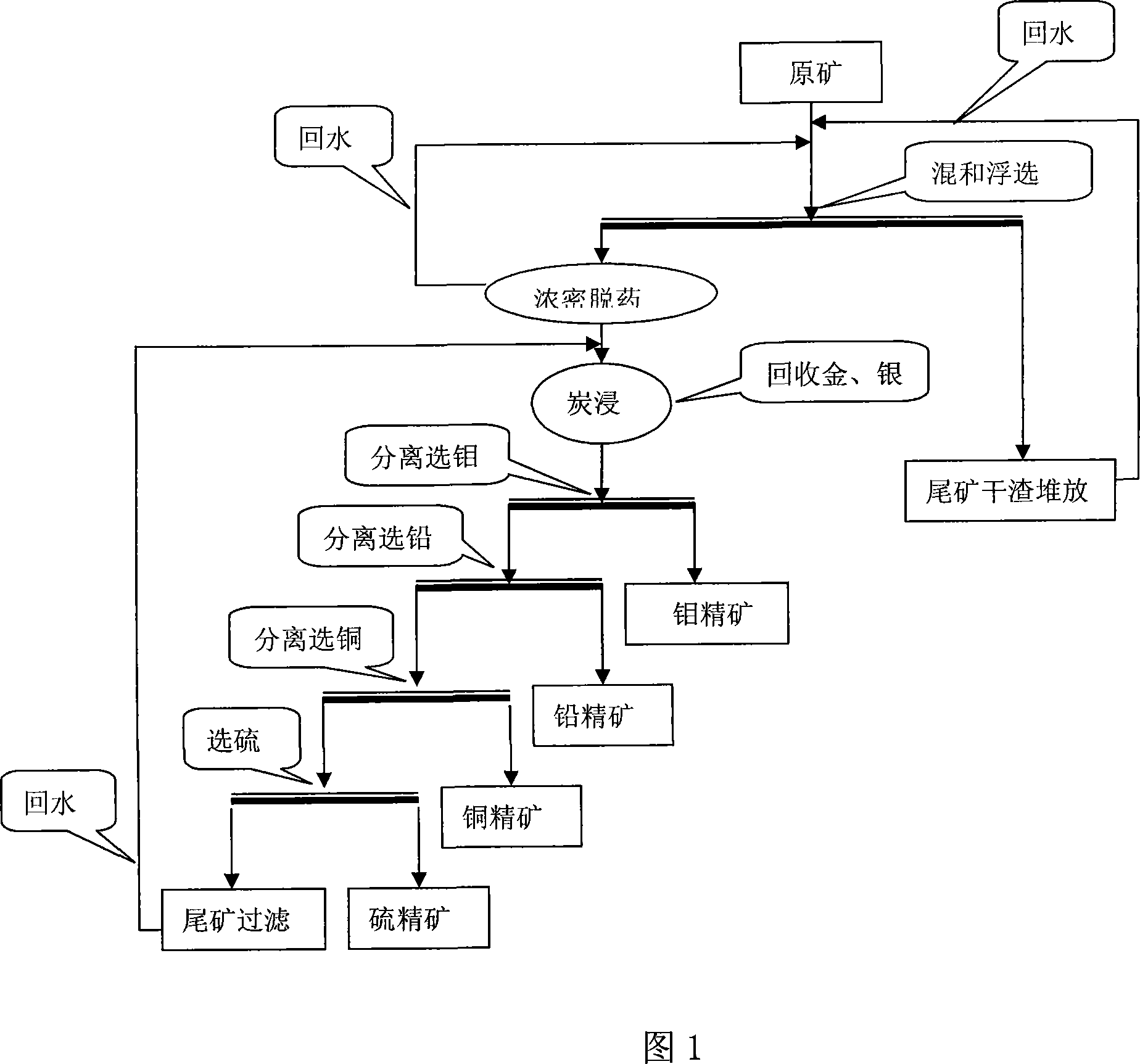

[0021] like figure 1 As shown, the method for comprehensive recovery of molybdenum-containing polymetallic gold ore resources of the present invention specifically comprises the following steps:

[0022] (1) First, the molybdenum-containing gold ore is subjected to traditional techniques such as crushing and grinding, and then a full-mixed flotation method is used to flotation useful metal elements into a mixed concentrate, and the tailings are discarded; the added in this step The medicament and order are: regulator sodium sulfate 1000g / t, slime dispersant water glass 700g / t, sodium hexametaphosphate 800g / t, inhibitor kerosene 300g / t, sodium oleate 200g / t, activator copper sulfate 150g / t, collector xanthate 70g / t, foaming agent No. 2 oil 100g / t; fully mixed flotation adopts a process of roughing once, sweeping twice, and selecting three times; (2) using traditional CCL carbon slurry wet The gold leaching method is used to recover gold and silver; the tailings after gold lea...

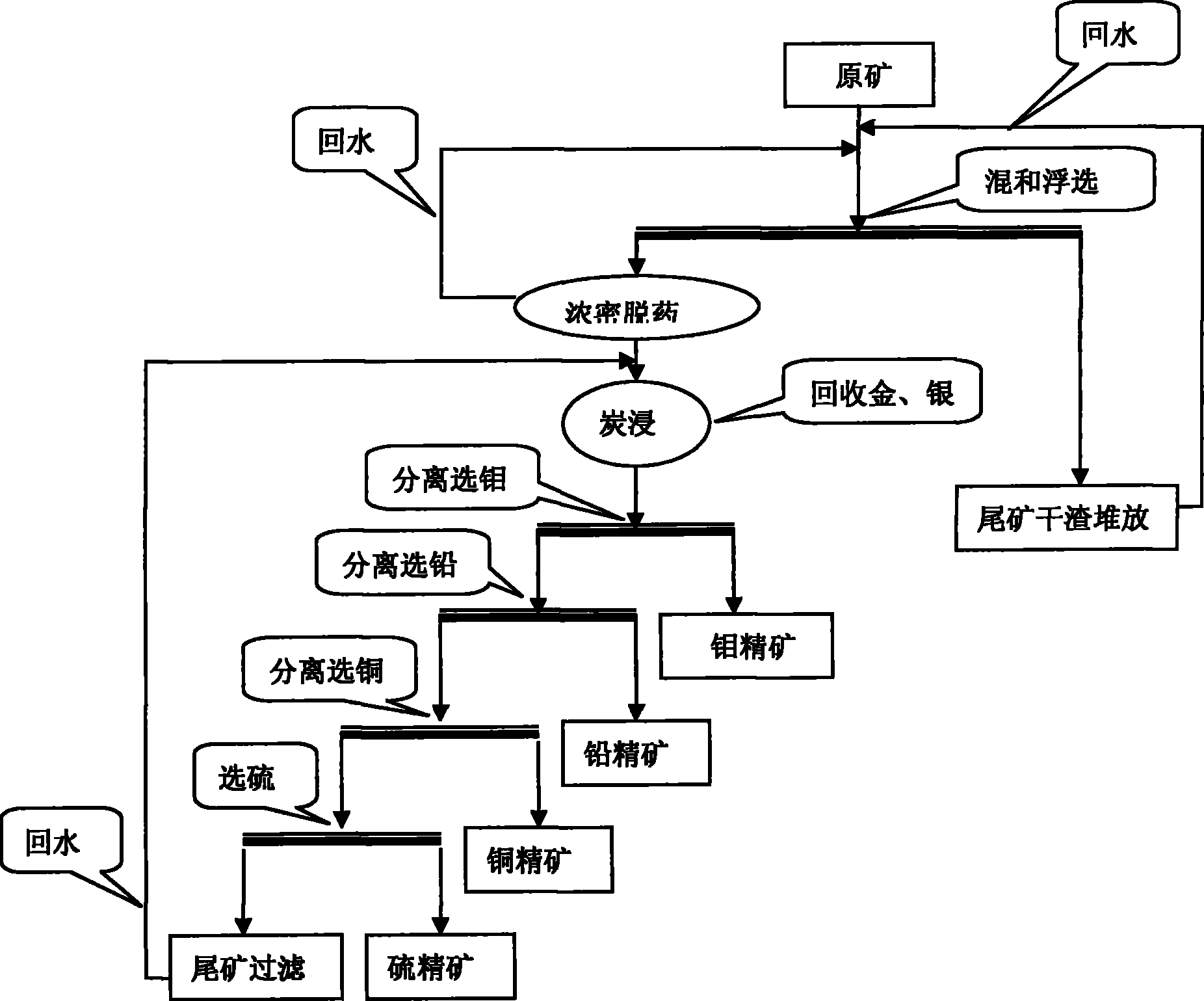

Embodiment 2

[0024] The method for comprehensively recovering molybdenum-containing polymetallic gold ore resources of the present invention specifically comprises the following steps: (1) firstly, the molybdenum-containing gold ore is subjected to traditional processes such as crushing and grinding, and then adopts a full-mixed flotation method to extract useful metals Element flotation is mixed concentrate, and the tailings are discarded; the reagents and order added in this step are: regulator sodium sulfate 1500g / t, slime dispersant sodium silicate 1000g / t, sodium hexametaphosphate 1000g / t, Inhibitor kerosene 500g / t, sodium oleate 300g / t, activator copper sulfate 200g / t, collector xanthate 100g / t, foaming agent No. 2 oil 150g / t; fully mixed flotation adopts one roughing, Secondary sweeping and three-time beneficiation process; (2) adopting the traditional CCL carbon slurry wet gold leaching method to recover gold and silver; the tailings after gold leaching are used for the next step to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com