Hard coating excellent in sliding property and method for forming same

A hard film and sliding technology, applied in the direction of ion implantation plating, coating, metal material coating technology, etc., can solve the problems of insufficient burning resistance, insufficient use, poor burning resistance, etc., to achieve friction Reduced carbon content, increased carbon content, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

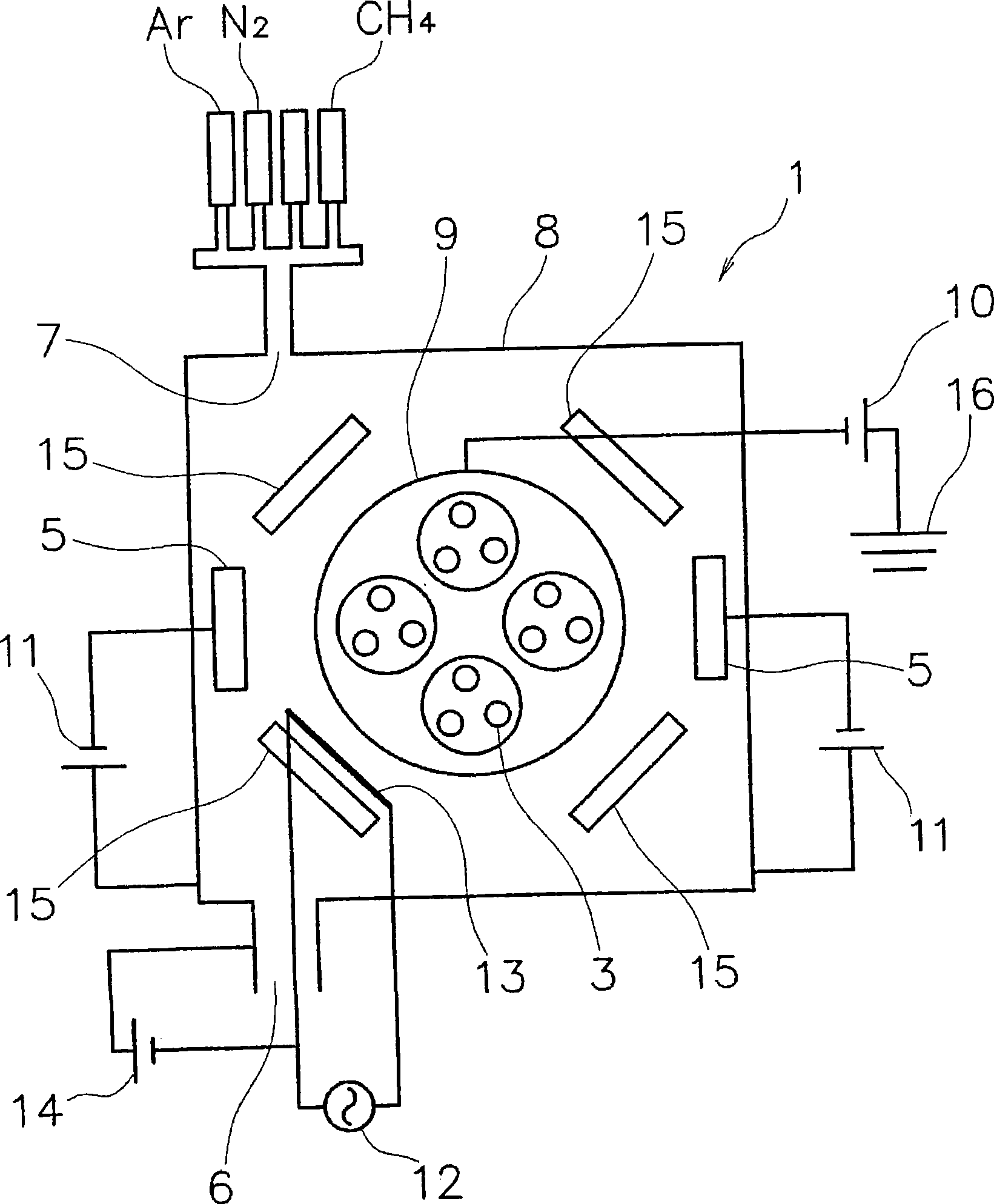

[0095] Using a metal target composed of metal element M or a composite target composed of metal elements M and B, using figure 1 In the cathode discharge type arc ion plating apparatus shown, films having the respective compositions shown in Table 1 were formed on the substrate surface. In this Example 1, first, in order to confirm the composition of the coating and measure the hardness of the coating, a cemented carbide whose surface was mirror-polished was used as a substrate, and coatings of the compositions shown in Table 1 were formed on the surface. In addition, as a sliding test, an SKD11 substrate (hardness HRC60) was used as the base material. In order to improve the adhesion to the surface of the base material, after forming a CrN layer with a thickness of 3 μm, the surface of each layer shown in Table 1 was formed on the surface. composed of membranes.

[0096] Initially, these substrates were placed on the substrate platform of the arc ion plating device, and then...

Embodiment 2

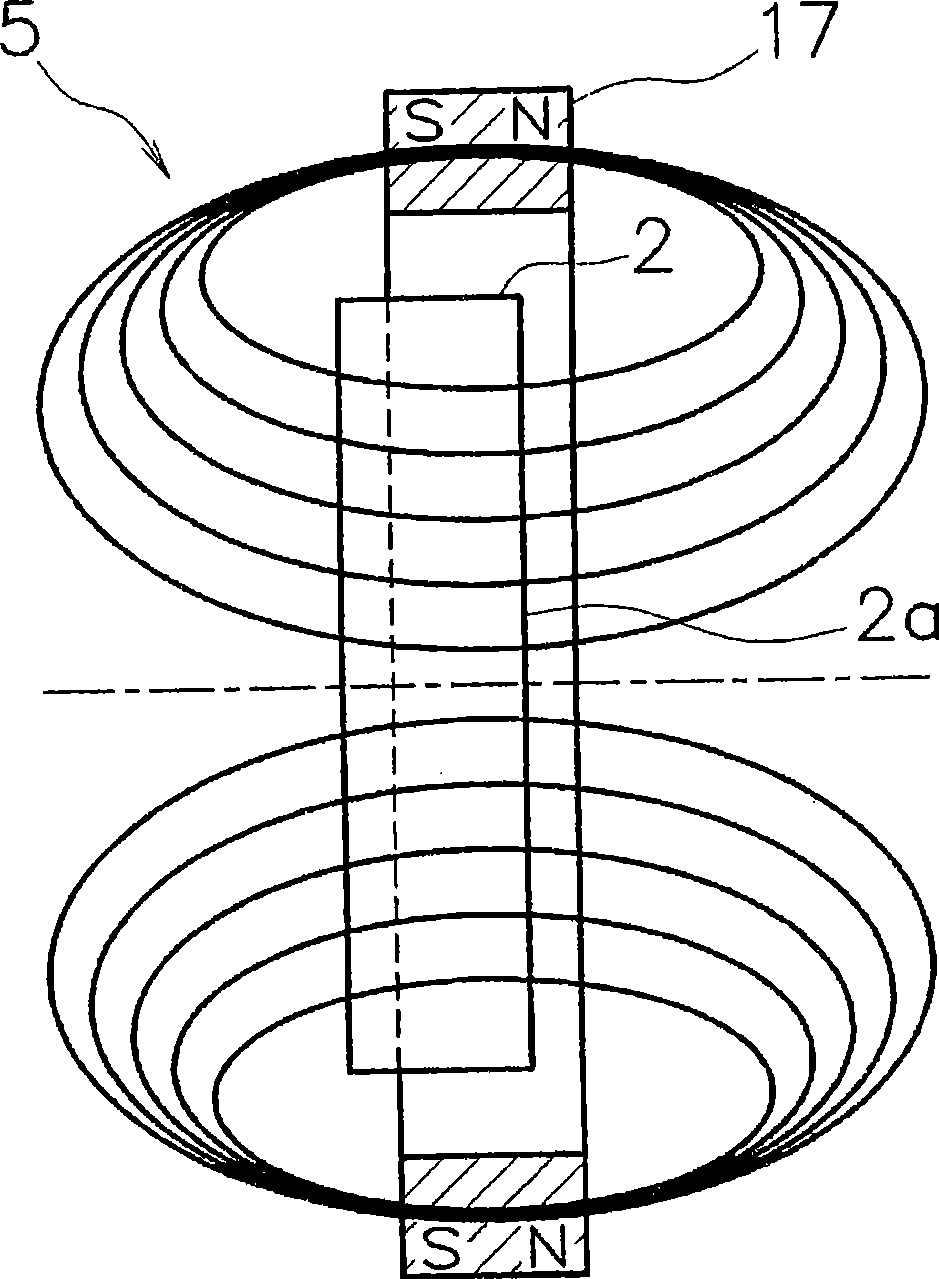

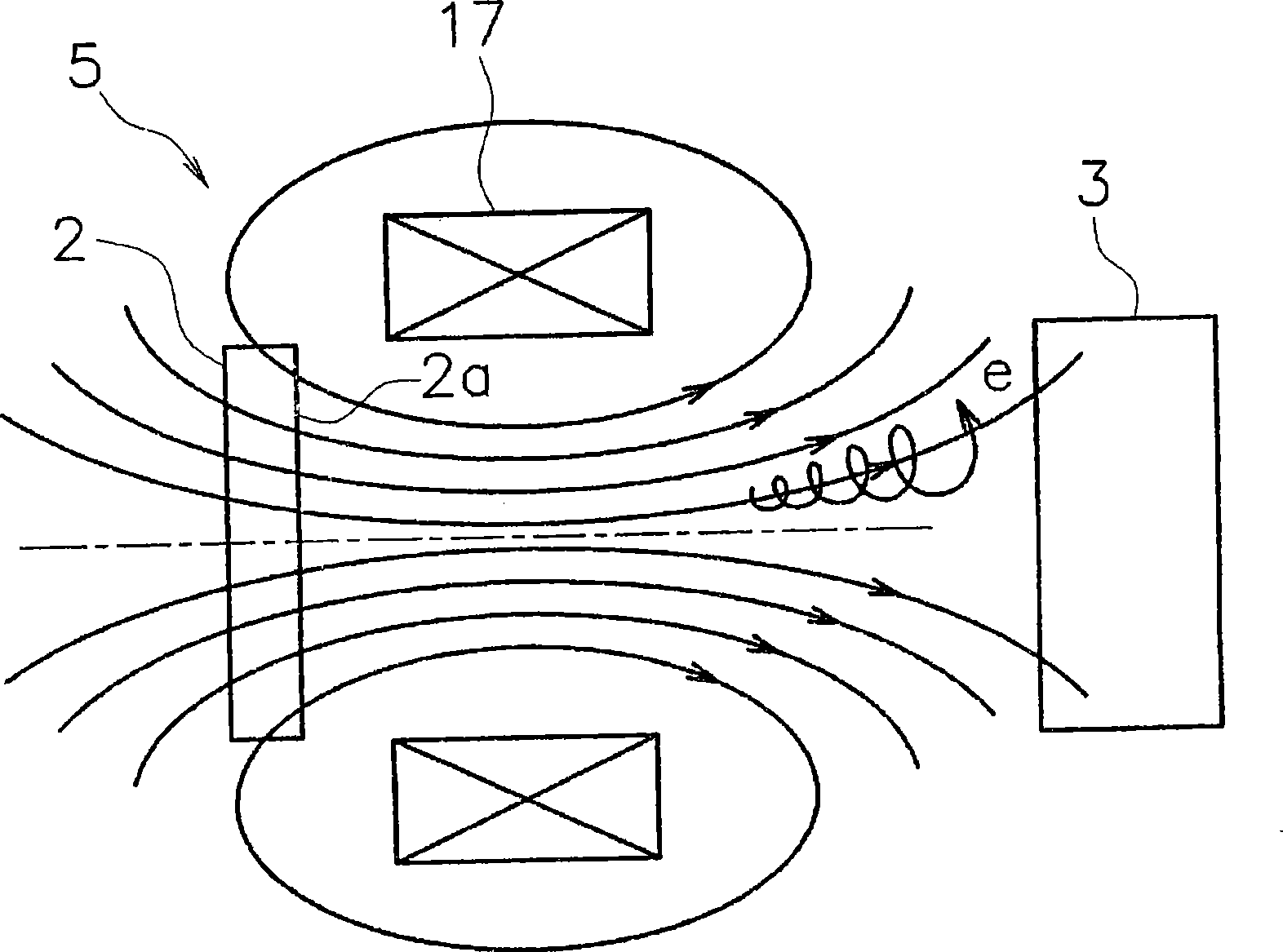

[0117] As the metal element M, Ti is used as the metal target, the same as in Example 1, using such as figure 1 The cathode discharge type arc ion plating device shown makes the arc current, methane (CH 4 ) The partial pressure was varied as shown in Table 2, and a superhard alloy whose surface was mirror-polished was used as a base material, and a hard film was formed on the surface. Also, the arc evaporation source used, that is, the evaporation source, is figure 2 shown using evaporation source A, image 3 shown using evaporation source B, Figure 4 The three shown use evaporation source C. The substrate voltage during film formation was 200V.

[0118] Also, in Example 2, only Ar and methane (CH 4 ) gas, other experimental conditions follow the experimental conditions of embodiment 1 to carry out. Confirmation of the component composition of the film was analyzed by an electron beam microanalyzer (EPDA). The results of its analytical confirmation are shown in Table ...

Embodiment 3

[0128] The metal element M is W, and W composed of WC is used as a target 0.5 C 0.5 Target (hot pressed product ¢100mm), with figure 1 In the shown cathode discharge type arc ion plating apparatus, a hard film containing W is formed on the surface of the substrate.

[0129] As the conditions for forming a hard film containing W, the arc current was 150A, methane (CH 4 ) flow ratio at 0 to 30vol%, nitrogen (N 2 ) The flow rate ratio is changed between 0 and 30vol%, and then Ar is supplied into the vacuum container to adjust the total pressure to 1.33Pa. In the case of No. 15 to 17 with added B, supply B into the vacuum container 2 h 6 gas. The film forming temperature was 400°C, and the bias voltage was 100V.

[0130] The film thickness of the formed hard film containing W was 10 μm, and the crystal structure of this film was identified by X-ray diffraction. The conditions for X-ray diffraction were to use Cukα as a line source, and measure the region of 10° to 100° by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com