Group III nitride compound semiconductor LED and production method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied to semiconductor devices, electrical components, circuits, etc., and can solve problems affecting the quality of crystal epitaxial growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

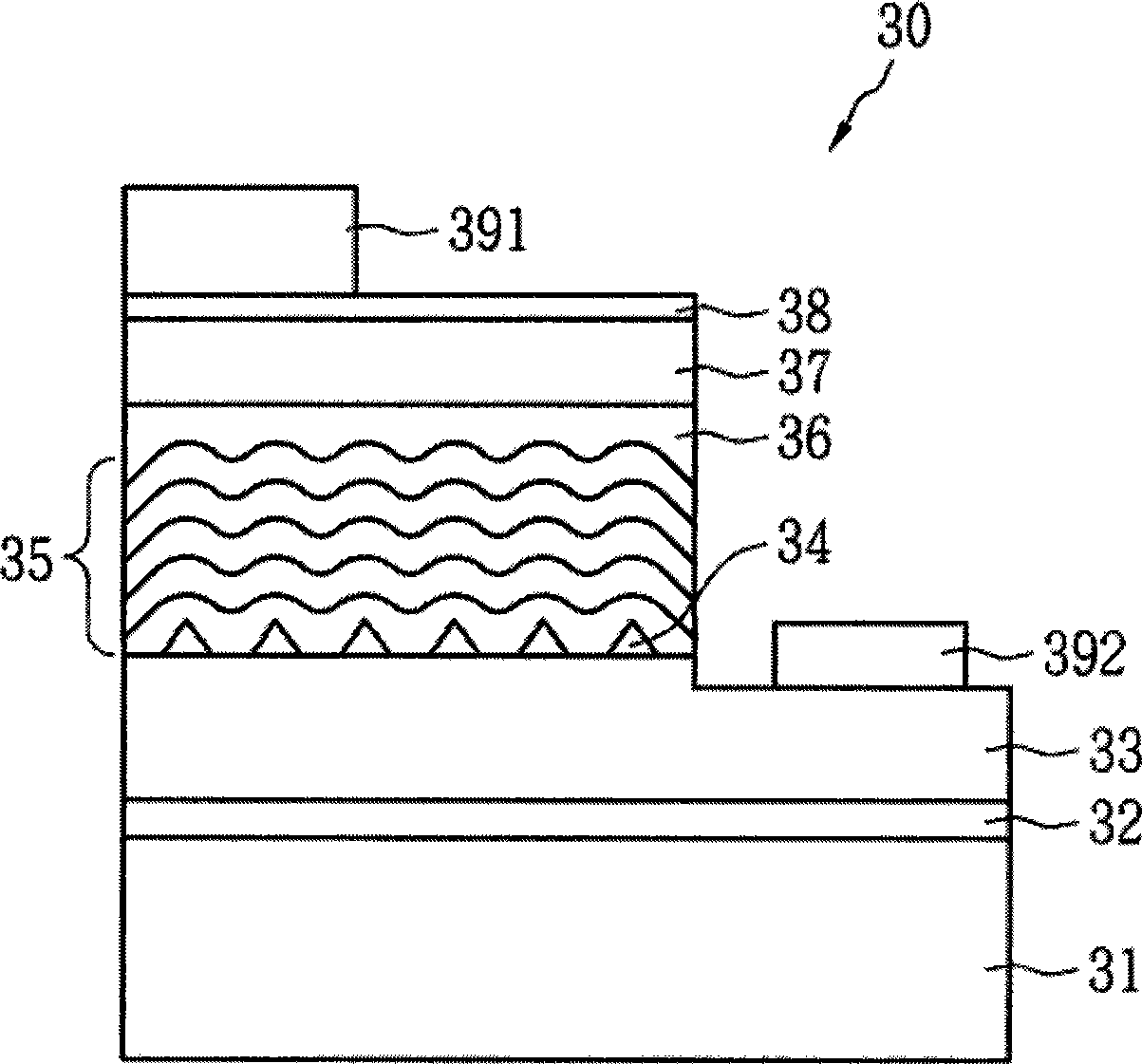

[0025] Figure 4 It is a schematic cross-sectional view of a Group III nitrogen compound semiconductor light-emitting diode of the present invention. The light-emitting diode 40 includes a substrate 41, a buffer layer 42, an N-type (or called first-type) semiconductor material layer 43, a conformal active layer 44, and a P-type (or called second-type) semiconductor material layer 45. An N-type electrode 47 is provided on the surface of the N-type semiconductor material layer 43 , and a P-type electrode 46 is provided on the surface of the P-type semiconductor material layer 45 .

[0026] Generally speaking, to manufacture the light emitting diode 40, a substrate 41 is firstly provided, such as: sapphire (that is, aluminum oxide compound Al 2 o 3 ), silicon carbide (SiC), silicon, zinc oxide (ZnO), magnesium oxide (MgO), gallium arsenide (GaAs), etc., and different material layers are formed on the substrate 41 . Because the substrate 41 does not match the lattice constant o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com