Manufacturing method of epitaxial wafer of GaN-based light emitting diode

A technology of light-emitting diodes and epitaxial wafers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems of low luminous efficiency of GaN-based light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

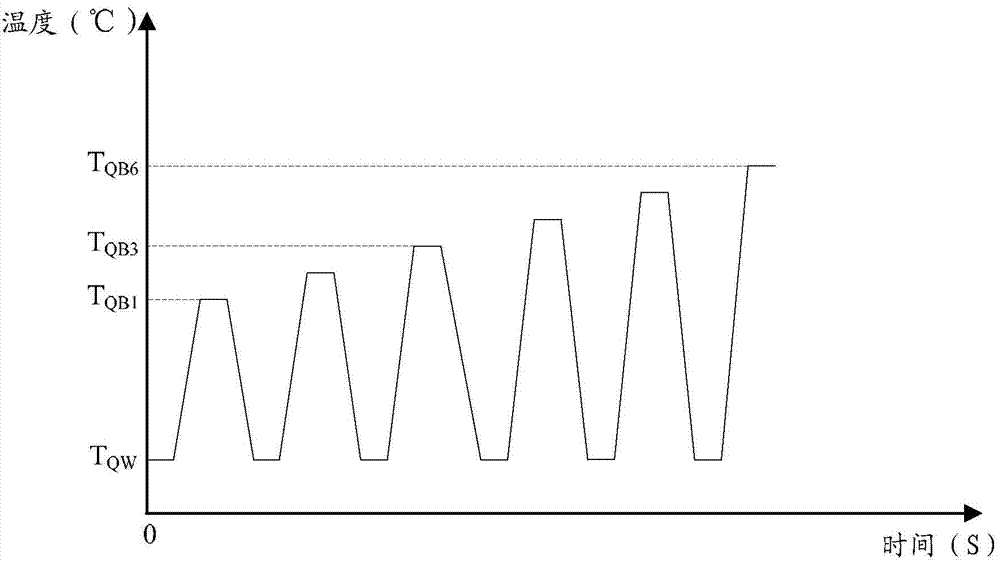

Embodiment 1

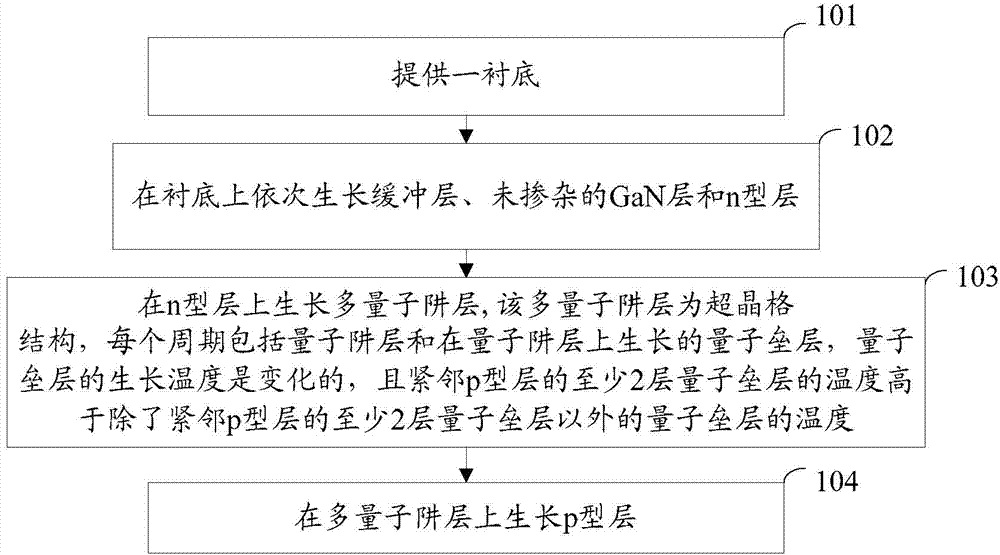

[0029] An embodiment of the present invention provides a method for preparing an epitaxial wafer of a GaN-based light-emitting diode, see figure 1 , the method includes:

[0030] Step 101: Provide a substrate.

[0031] The substrate includes, but is not limited to, a sapphire substrate.

[0032] When it is realized, the sapphire substrate can be heated to 1060°C in a MOCVD (Metal-organic Chemical Vapor Deposition) reaction chamber, and the sapphire substrate can be annealed and nitrided in a hydrogen atmosphere for 10 minutes. to clean the substrate surface.

[0033] Step 102: growing a buffer layer, an undoped GaN layer and an n-type layer sequentially on the substrate.

[0034] Wherein, the buffer layer may be a gallium nitride layer, an aluminum nitride layer, or an aluminum gallium nitride layer or the like.

[0035] The n-type layer may be a Si-doped GaN layer, but not limited to Si-doped. During implementation, silane can be selected to complete the silicon doping i...

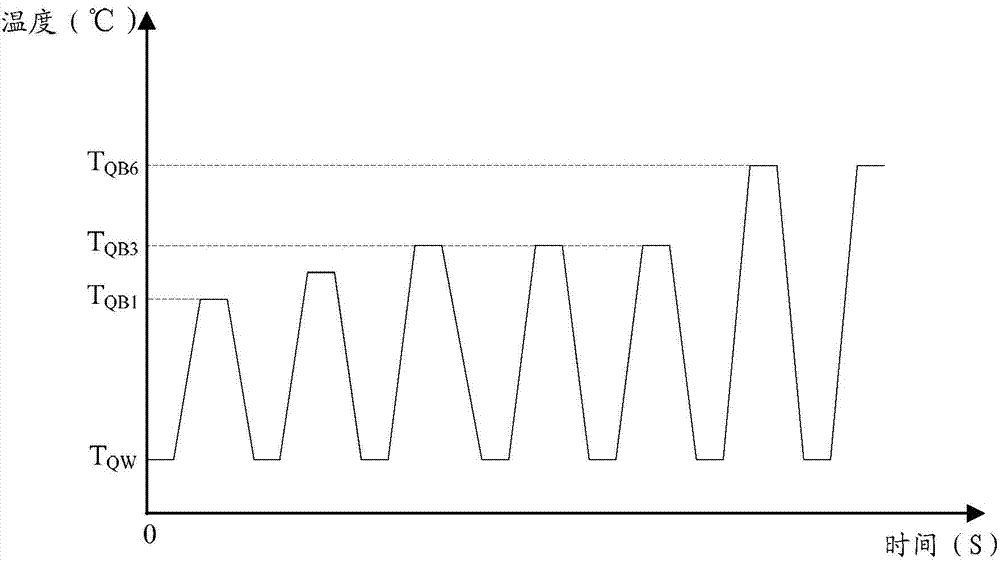

Embodiment 2

[0060] An embodiment of the present invention provides a method for preparing an epitaxial wafer of a GaN-based light-emitting diode. The method for preparing the epitaxial wafer in this embodiment is basically the same as that of Embodiment 1, except that the quantum barrier layer next to the p-type layer is The growth thickness is smaller than that of the quantum barrier layers other than the quantum barrier layer immediately adjacent to the p-type layer.

[0061] Specifically, starting from the side of the n-type layer, the growth thickness of all the quantum barrier layers in the multi-quantum well layer is gradually reduced, or the growth thickness of all the quantum barrier layers is kept constant and then gradually reduced.

[0062] When implemented, the growth thickness of the quantum barrier layer can be controlled by changing the growth time or growth rate of the quantum barrier layer. Specifically, the growth thickness of the quantum barrier layer is proportional to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com