Method for reproducing waste rubber by using microorganism

A technology for regenerating waste rubber and microorganisms, applied in the field of waste rubber regeneration, can solve the problems of rubber main chain bond oxidation, serious secondary pollution, and low production efficiency, and achieve the effects of mild conditions, low equipment requirements, and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

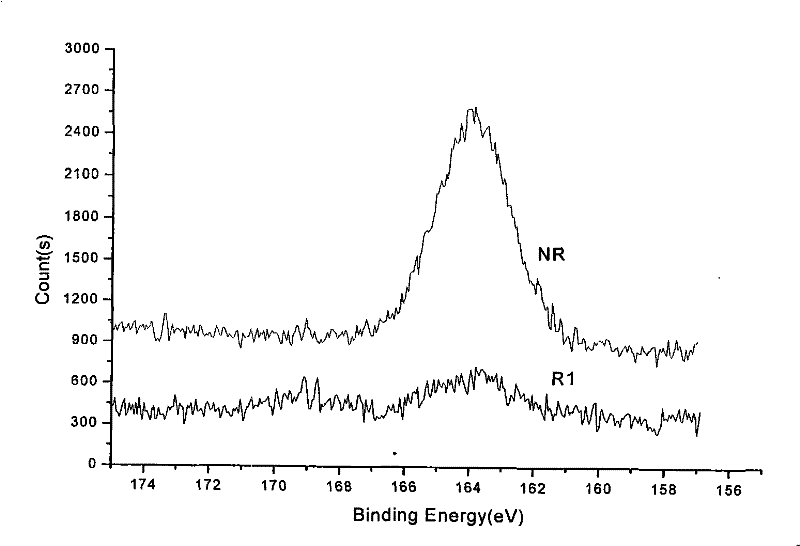

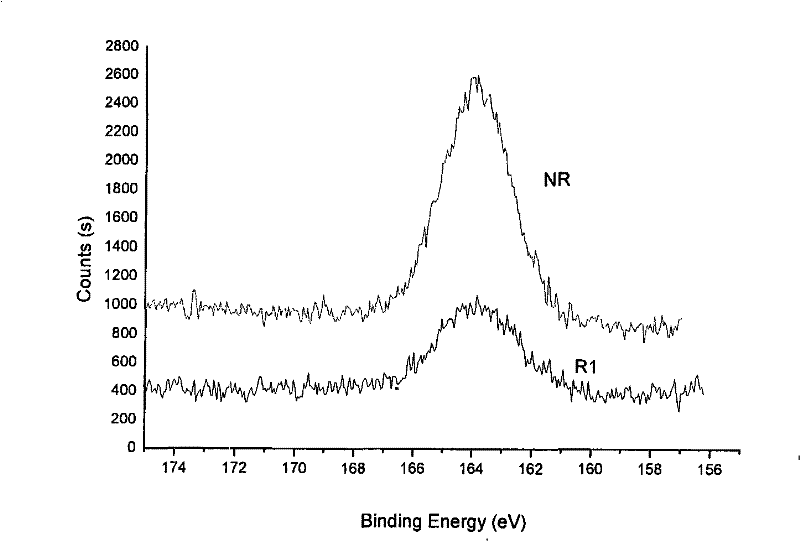

Image

Examples

Embodiment 1

[0049] 1. Materials

[0050] 1 strain: Saccharomyces cerevisiae.

[0051] 2 Natural rubber powder: Yunbiao 1# Yunnan Natural Rubber Industry Co., Ltd.

[0052] 3 media

[0053](1) Slant medium: glucose 20g / L, yeast extract powder 10g / L, peptone 10g / L, agar 15g / L; pH 5.0-6.0, sterilized at 115°C, 0.1Mpa for 30min;

[0054] (2) Seed medium: glucose 50g / L, yeast extract powder 10g / L, peptone 10g / L, malt extract powder 5g / L; pH 5.0-6.0, 115°C, 0.1Mpa sterilization for 30min;

[0055] (3) Desulfurization medium: glucose 40g / L, yeast extract powder 15g / L, peptone 15g / L, malt extract powder 5g / L, MgSO 4 ·7H 2 O5g / L, K 2 HPO 4 ·3H 2 O 1g / L, KH 2 PO 4 1g / L, ZnSO 4 0.044g / L, FeSO 4 ·7H 2 O0.03g / L, CuCl 2 0.016g / L, MnSO 4 0.019g / L; pH 5.0, 115°C, 0.1Mpa sterilization for 20min.

[0056] 4 Instruments and equipment: shaking incubator, reactor.

[0057] 2. Method

[0058] 1 Culture of seed solution

[0059] (1) Primary seed liquid: take Saccharomyces cerevisiae cells pr...

Embodiment 2

[0065] 1. Materials

[0066] 1 strain: Saccharomyces cerevisiae.

[0067] 2 Natural rubber powder: Yunbiao 1# Yunnan Natural Rubber Industry Co., Ltd.

[0068] 3 media:

[0069] (1) Slant medium: glucose 20g / L, yeast extract powder 10g / L, peptone 10g / L, agar 15g / L; pH 5.0-6.0, 115°C, 0.1Mpa sterilization for 30min;

[0070] (2) Seed medium: glucose 50g / L, yeast extract powder 10g / L, peptone 10g / L, malt extract powder 5g / L; pH 5.0-6.0, 115°C, 0.1Mpa sterilization for 30min;

[0071] (3) Desulfurization medium: glucose 40g / L, yeast extract powder 15g / L, peptone 15g / L, malt extract powder 5g / L, MgSO 4 ·7H 2 O5g / L, K 2 HPO 4 ·3H 2 O 1g / L, KH 2 PO 4 1g / L, ZnSO 4 0.044g / L, FeSO 4 ·7H 2 O0.03g / L, CuCl 2 0.016g / L, MnSO 4 0.019g / L; pH5.5, 115℃, 0.1Mpa sterilization for 20min.

[0072] 4 Instruments and equipment: shaking incubator, reactor.

[0073] 2. Method

[0074] 1 Culture of seed solution

[0075] (1) Primary seed liquid: take Saccharomyces cerevisiae cells pres...

Embodiment 3

[0081] 1. Materials

[0082] 1 strain: Saccharomyces cerevisiae.

[0083] 2 Natural rubber powder: Yunbiao 1# Yunnan Natural Rubber Industry Co., Ltd.

[0084] 3 media

[0085] (1) Slant medium: glucose 20g / L, yeast extract powder 10g / L, peptone 10g / L, agar 15g / L; pH 5.0-6.0, 115°C, 0.1Mpa sterilization for 30min;

[0086] (2) Seed medium: glucose 50g / L, yeast extract powder 10g / L, peptone 10g / L, malt extract powder 5g / L; pH 5.0-6.0, 115°C, 0.1Mpa sterilization for 30min;

[0087] (3) Desulfurization medium: glucose 40g / L, yeast extract powder 15g / L, peptone 15g / L, malt extract powder 5g / L, MgSO 4 ·7H 2 O5g / L, K 2 HPO 4 ·3H 2 O 1g / L, KH 2 PO 4 1g / L, ZnSO 4 0.044g / L, FeSO 4 ·7H 2 O0.03g / L, CuCl 2 0.016g / L, MnSO 4 0.019g / L; pH5.0-6.0, 115℃, 0.1Mpa sterilization for 20min.

[0088] 4 Instruments and equipment: shaking incubator, reactor.

[0089] 2. Method

[0090] 1 Culture of seed solution

[0091] (1) Primary seed liquid: take Saccharomyces cerevisiae cells p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com