Method and device for removing cadmium and thallium from high purity indium production

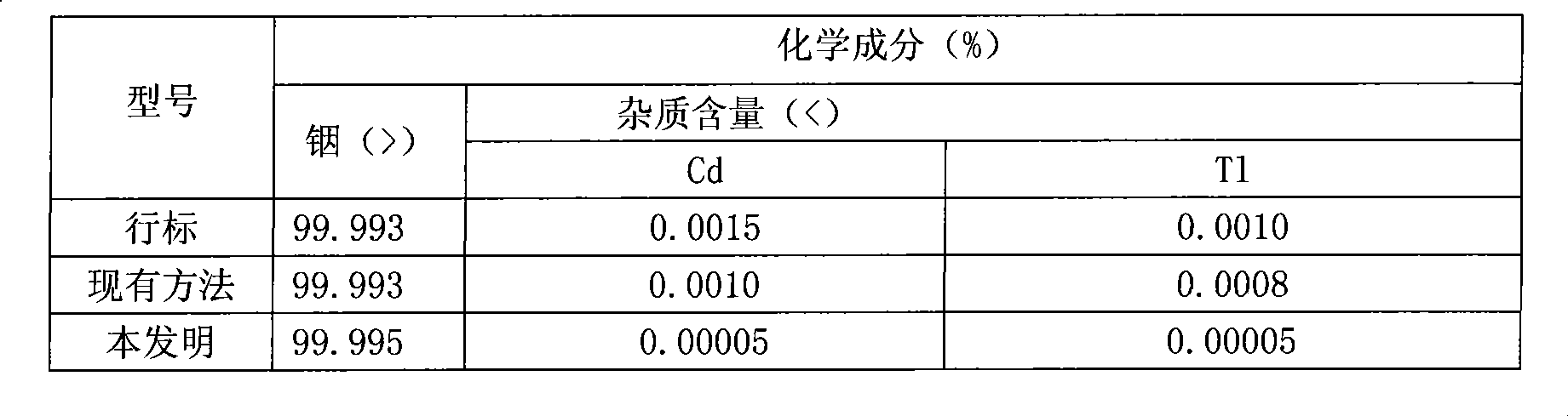

A high-purity, production process technology, applied in the field of high-purity indium production, can solve the problems of long operation time, high production cost, large environmental pollution, etc., and achieve the effects of simple equipment processing, fast production speed and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

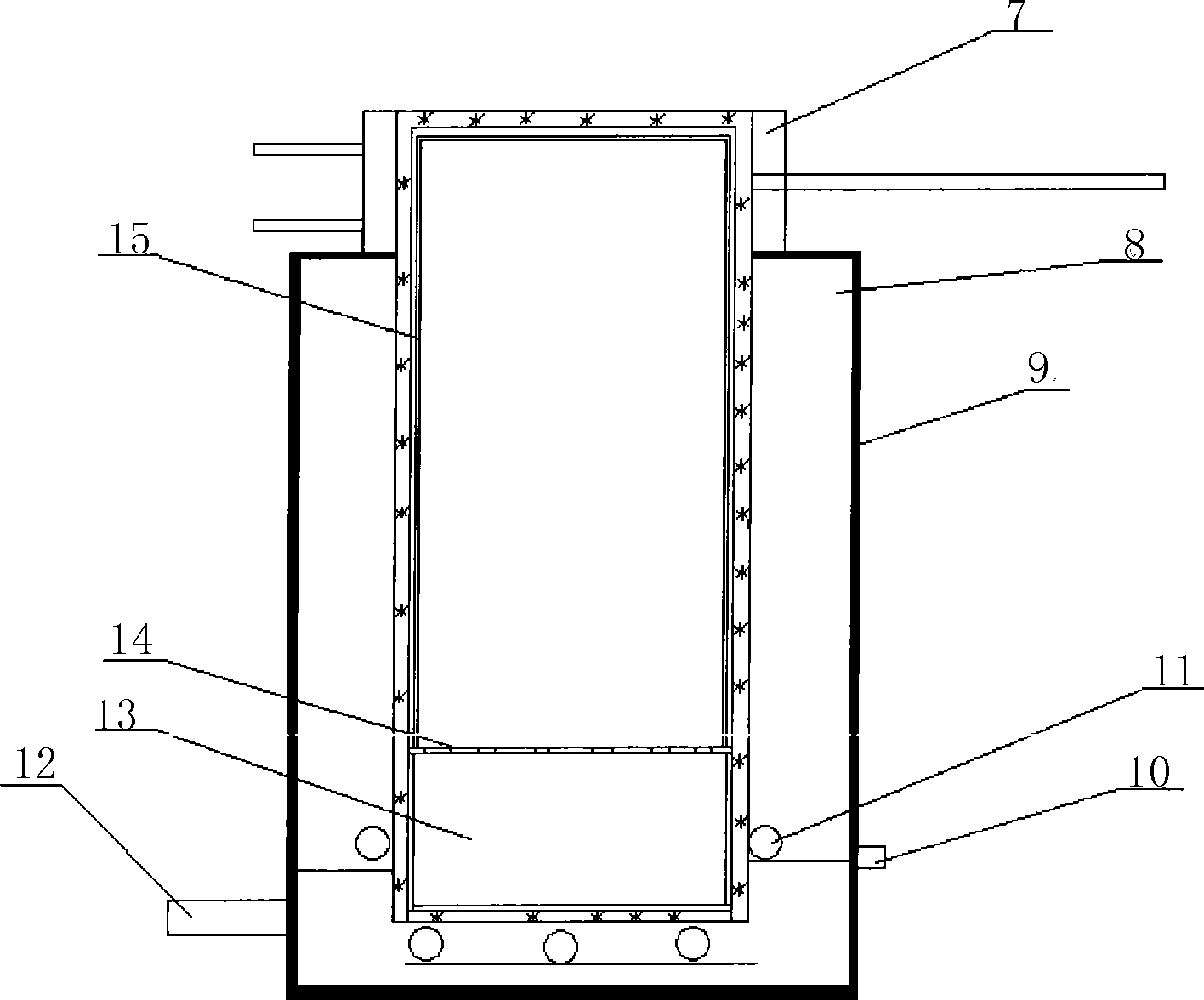

[0015] The specific technological process of the present invention is: the first step, put indium into the crucible and put it into the vacuum tank, then place the cylindrical titanium plate on the crucible cover, cover the titanium sealing sleeve, close the vacuum tank cover, open Water cooling system, start the vacuum pump; control the vacuum degree below 10Pa; the second step, control the temperature at the bottom of the crucible at 400-1000 degrees, keep it warm for 1-5 hours, completely volatilize the cadmium and thallium impurities, and finally leave the high-purity indium in the Crucible, to achieve the purpose of purification.

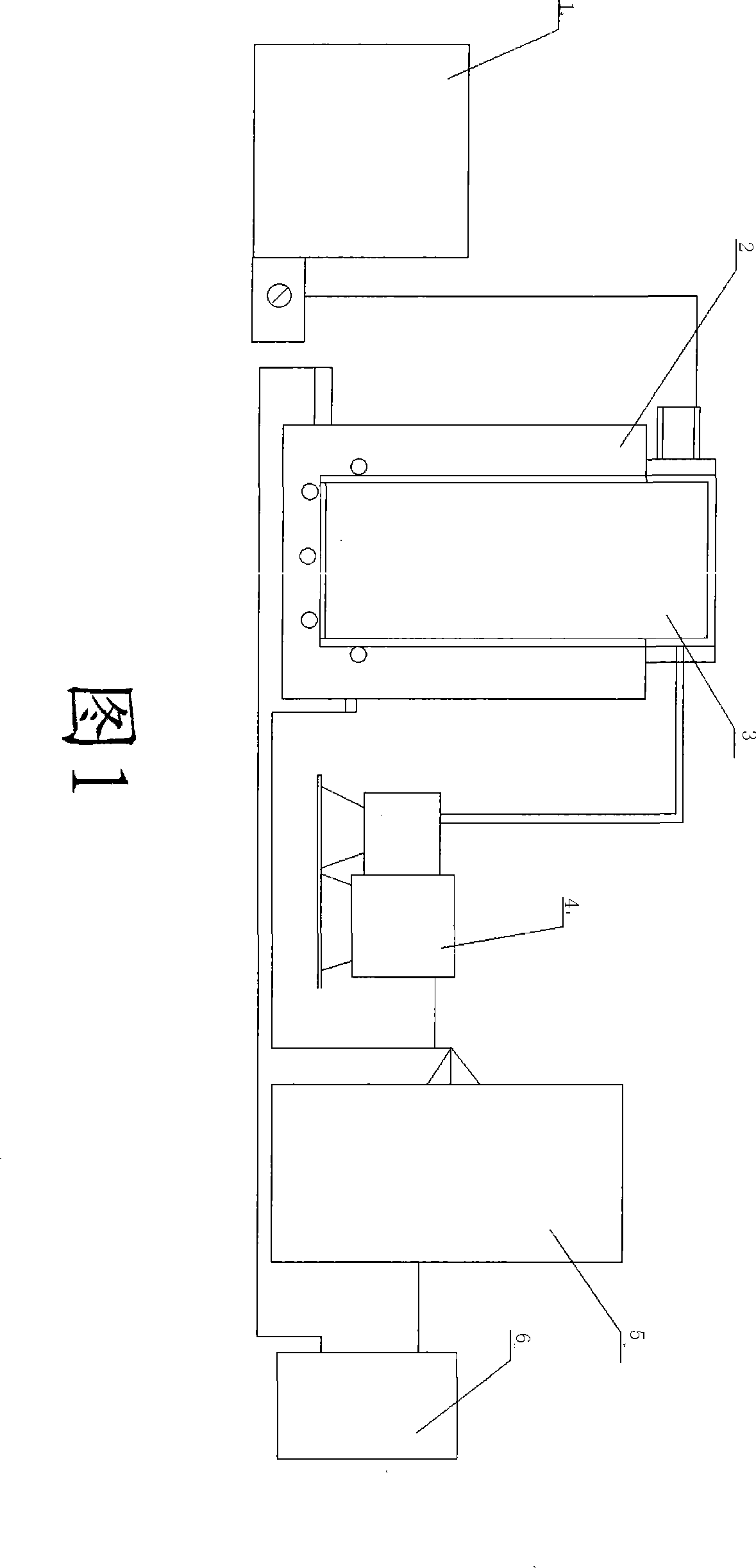

[0016] Figure 1, figure 2 As shown, the present invention contains a cooling water circulation device 1, a well-type electric furnace 2, a vacuum tank 3, a vacuum pump 4, an electric screen cabinet 5 and a tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com