Hard coat film and optically functional film

A hard coating film and hard coating technology, applied in the direction of optics, optical components, coatings, etc., to achieve the effects of maintaining transparency, improving adhesion, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

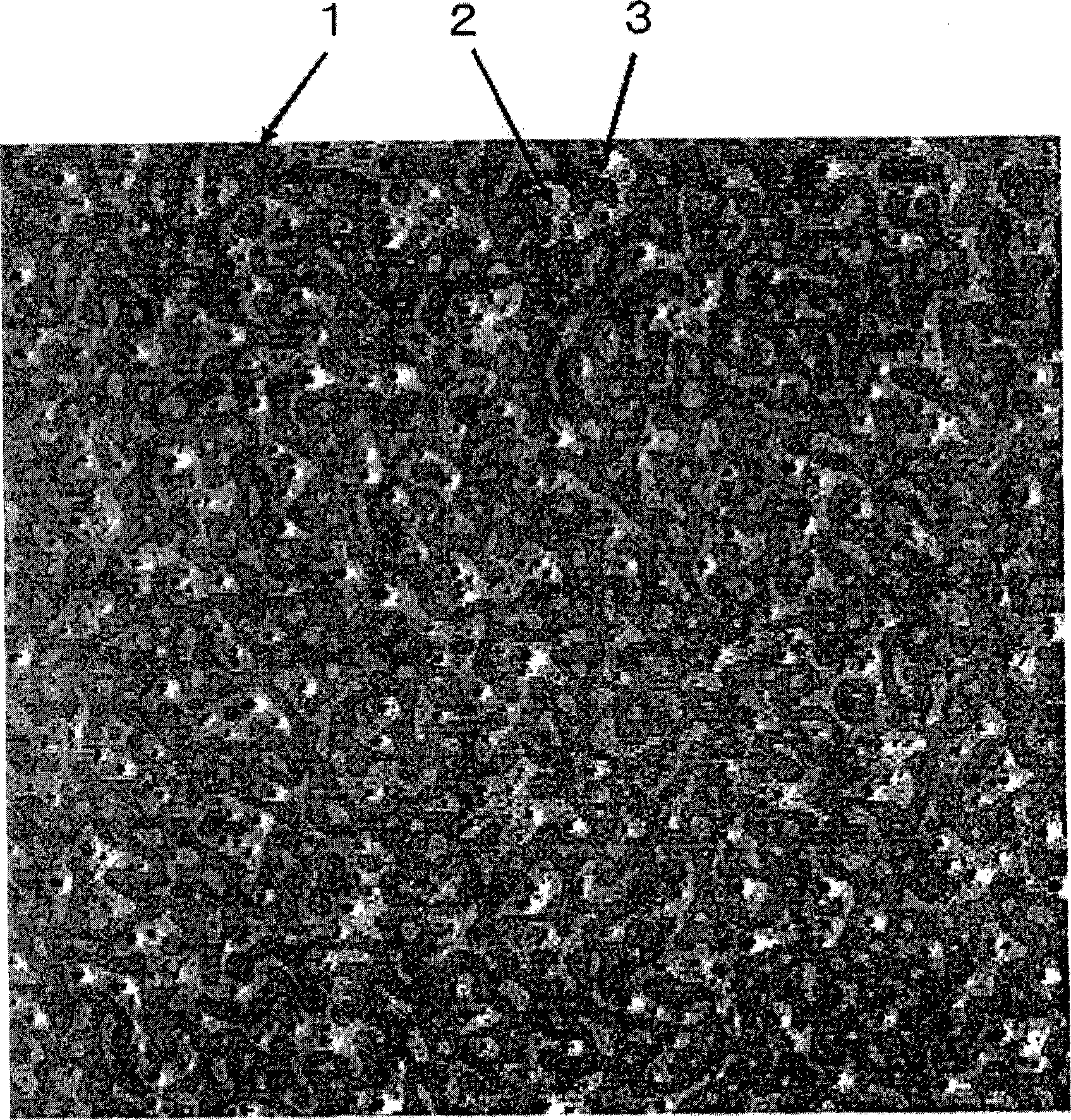

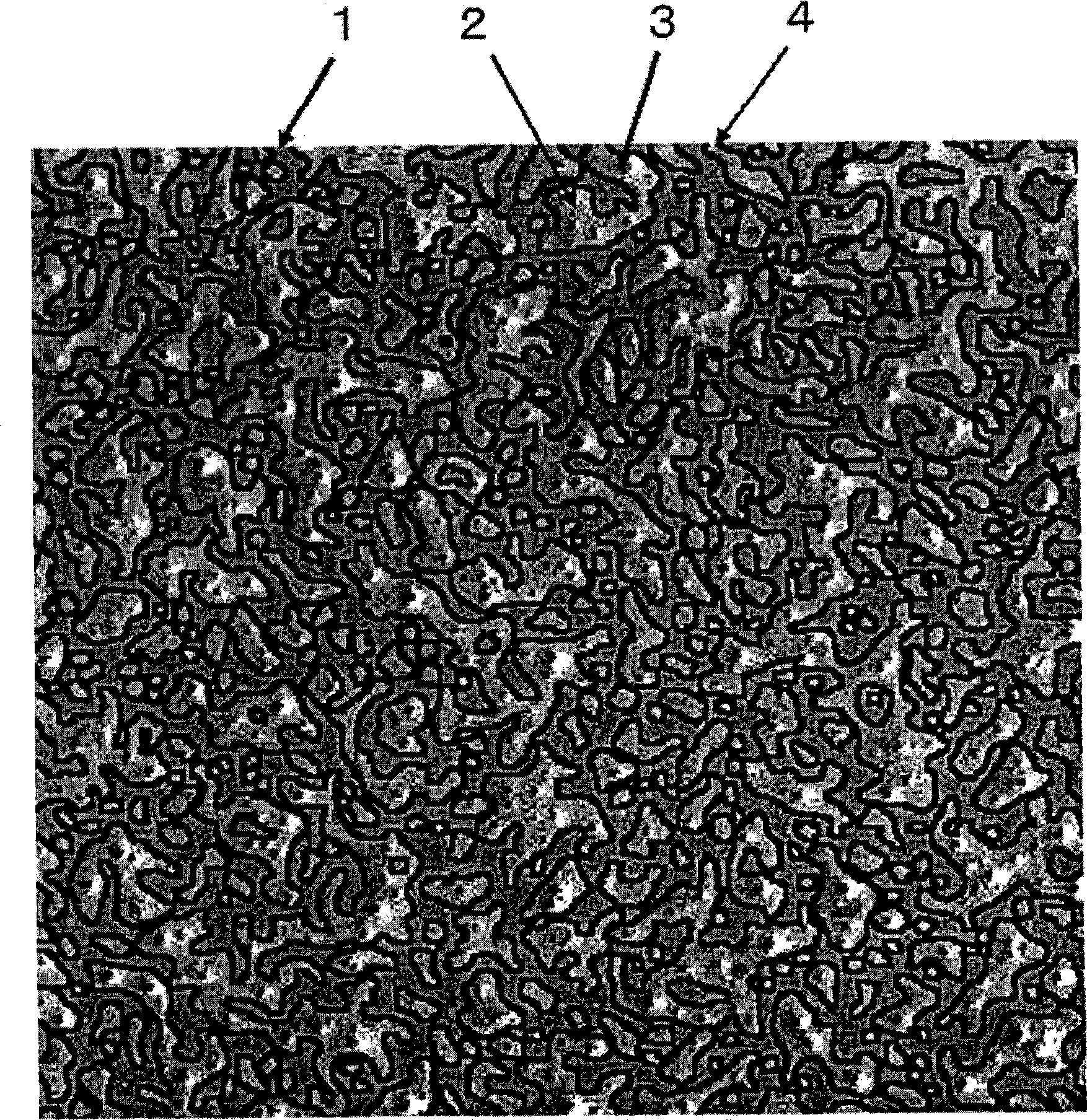

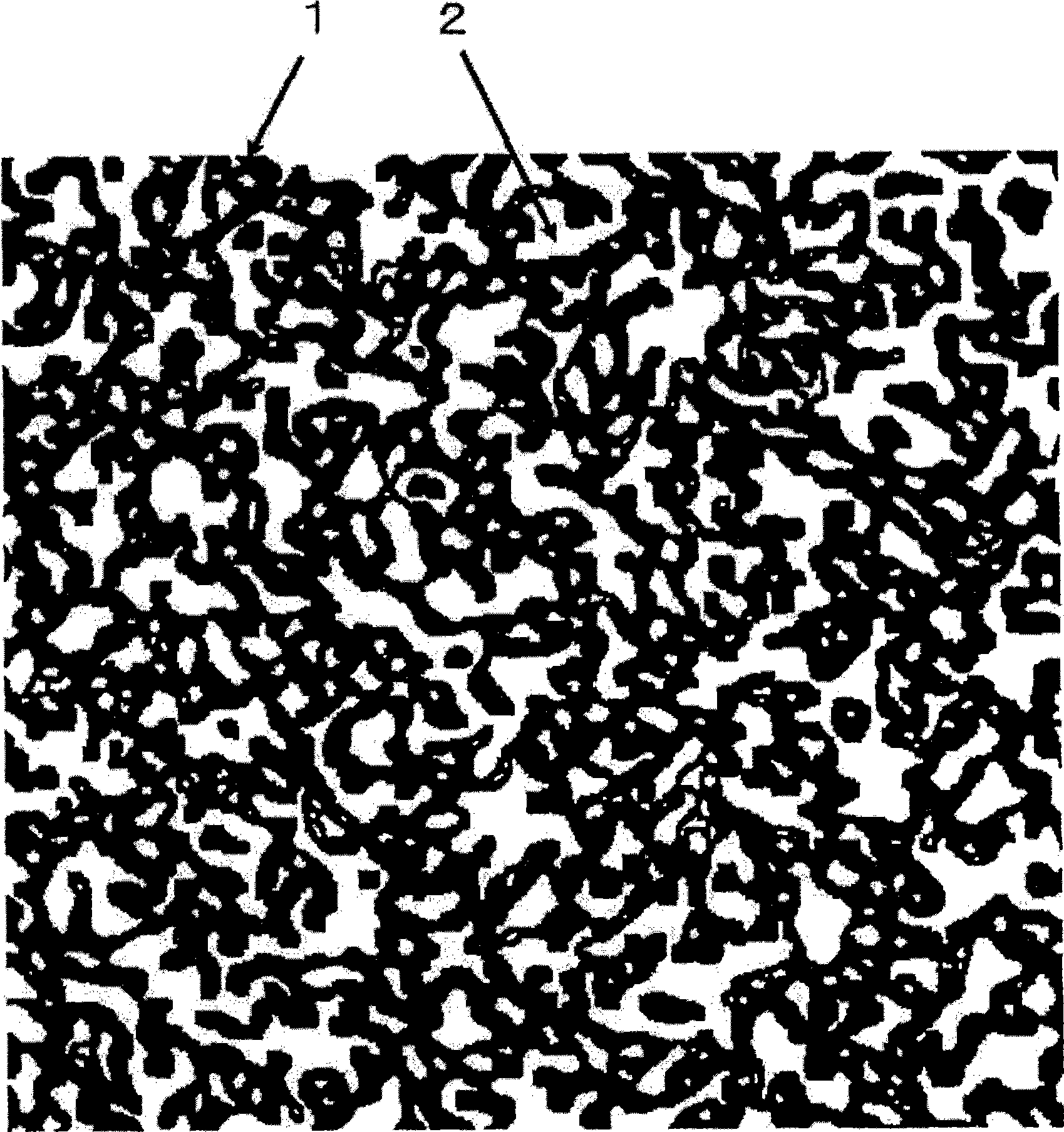

Image

Examples

Embodiment 1

[0466] (1) Preparation of coating liquid

[0467] The coating liquid used in the present invention is prepared as follows.

[0468] Dimethyl terephthalate (95 parts by mass), dimethyl isophthalate (95 parts by mass), ethylene glycol (35 parts by mass), neopentyl glycol (145 parts by mass), zinc acetate (0.1 parts by mass) and antimony trioxide (0.1 parts by mass) were placed in a reaction container, and a transesterification reaction was performed at 180° C. for 3 hours. Then add isophthalic acid-5-sodium sulfonate (6.0 parts by mass), carry out esterification reaction at 240°C for 1 hour, and then carry out polycondensation reaction at 250°C under reduced pressure (10-0.2mmHg). hours, a copolyester with a number average molecular weight of 19500 and a softening temperature of 60°C was obtained.

[0469] 7.5 parts by mass of a 30 mass % aqueous dispersion of the obtained copolyester (A), a 20 mass % aqueous solution ( 11.3 parts by mass of Elastron H-3 manufactured by Daiic...

Embodiment 2

[0486] As the surfactant used for the coating liquid in Example 1, 10% by mass of the fluorine-based cationic surfactant (manufactured by Neoos Co., Ltd., Futa-Jient 310) pretreated in the same manner as in Example 1 Except that the aqueous solution was used as the coating liquid B, it carried out similarly to Example 1, and obtained the adhesive modified polyester film.

[0487] Then, the hard coat layer C containing inorganic particles was laminated on one side in the same manner as in Example 1 on the surface of the adhesive modified layer B of the adhesive modified base film to obtain a hard coat film.

Embodiment 3

[0489] The temperature of each heat-fixing zone in the heat-fixing process of Example 1 is set as follows: the temperature of the first heat-fixing zone is 190°C, the temperature of the second heat-fixing zone is 205°C, and the temperature of the third heat-fixing zone is 220°C , the temperature in the fourth heat-fixing zone was 220° C., and the same method as in Example 1 was used to obtain an adhesively modified polyester film.

[0490] Then, the hard coat layer C containing inorganic particles was laminated on one side in the same manner as in Example 1 on the surface of the adhesive modified layer B of the adhesive modified base film to obtain a hard coat film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com