Method for preparing metoclopramide hydrochloride sustained-release capsule

A technology of metoclopramide hydrochloride and sustained-release capsules, which can be used in medical preparations containing active ingredients, pharmaceutical formulations, and devices for making medicines into special physical or taking forms, etc. Uniform, low drying efficiency, easy to break and other problems, to achieve the effect of good product quality, stable and reliable quality, and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

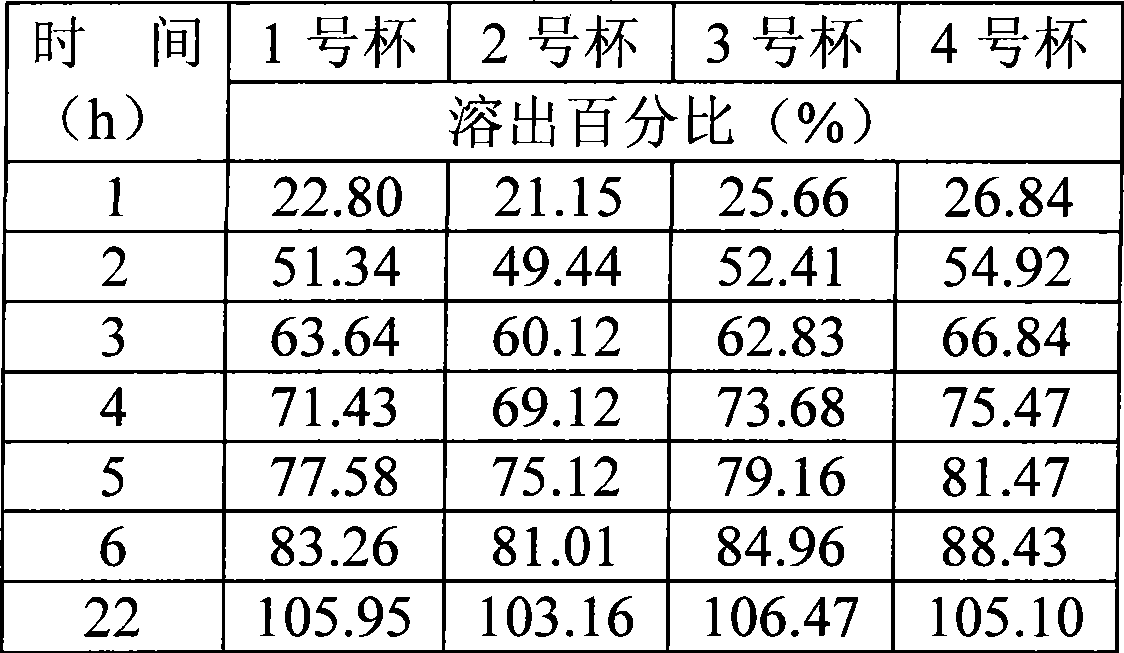

Embodiment 1

[0019] Add 20 g of metoclopramide hydrochloride into 20 ml of purified water, stir to dissolve, and adjust the pH to 4.2 with dilute hydrochloric acid. Add 4g of hypromellose (species code: E15) to 70ml of ethanol and stir to disperse thoroughly, then add 10ml of purified water to dissolve. Mix the above two solutions, add talc powder 6g. Stir to suspend the talc powder in the coating solution of the main drug layer, fluidize and coat 200g of blank pellets, and control the coating conditions: the inlet air temperature is 65°C, and the air inlet volume is 20M 3 / h, the spraying speed is 2.0g / min, and the temperature range of the product measured by the fluidized bed is 50±5°C during the whole process. The final weight of the coated pellets was 220.3 g after drying.

[0020] Add 111.1 g of ethyl cellulose water dispersion (type number: E-7-19040) to the beaker, add purified water to 185.7 g, and stir for 15 minutes. Take 216g of the pellets coated with the drug-coated layer, ...

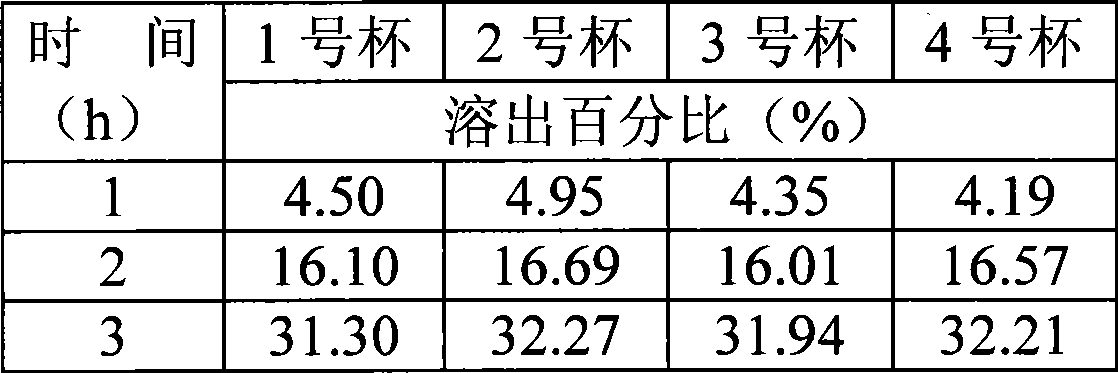

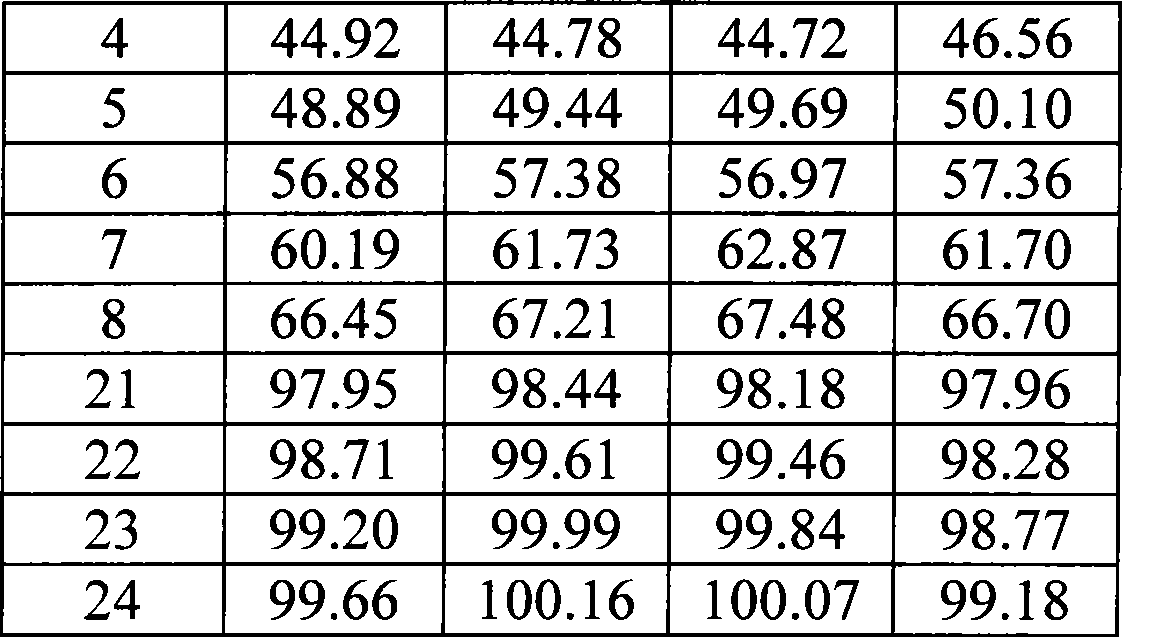

Embodiment 2

[0022] Add 70 g of metoclopramide hydrochloride to 70 ml of purified water, stir to dissolve, and adjust the pH to 5.0 with dilute hydrochloric acid. Measure 400ml of 80% ethanol, stir and add 40g of crospovidone, and stir for 20 minutes. Mix the above two solutions, fluidize and coat 500g blank pellets, control the coating conditions: air inlet temperature 70°C, air inlet volume 28M 3 / h, the spraying speed is 5.0g / min, and the temperature range of the product measured by the fluidized bed during the whole process is 55±5°C. The final weight of the coated pellets was 600.8g after drying.

[0023] Add 84.6 g of ethyl cellulose aqueous dispersion (type number: E-7-19040) to the beaker, add purified water to 142.8 g, and stir for 15 minutes. Take 300g of the pellets coated with the drug-coated layer, fluidize the coating, and control the coating conditions: the air inlet temperature is 40°C, and the air inlet volume is 20M 3 / h, the spray speed is 2.5g / min, and the temperatur...

Embodiment 3

[0025] Take 70g of metoclopramide hydrochloride and add 80ml of purified water, stir to dissolve, and adjust the pH to 3.8 with dilute hydrochloric acid. Measure 200ml of 80% ethanol, stir and add 30g of crospovidone, and stir for 20 minutes. Mix the above two solutions, add 6.6g of talcum powder, fluidize and coat 500g of blank pellets, control the coating conditions: air inlet temperature 50°C, air inlet volume 25M 3 / h, the spray speed is 7.0g / min, and the temperature range of the product measured by the fluidized bed is 40±5°C during the whole process. The final weight of the coated pellets was 592.2 g after drying.

[0026] Add 320 g of ethyl cellulose aqueous dispersion (species number: E-7-19040) to the beaker, add purified water to 533.3 g, and stir for 15 minutes. Take 400g of the pellets coated with the drug-coated layer, fluidize the coating, and control the coating conditions: the air inlet temperature is 40°C, and the air inlet volume is 20M 3 / h, the spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com