Terbinafine hydrochloride emulsifiable paste and preparation method thereof

A technology of terbinafine hydrochloride and naphthene cream, which is applied in the directions of ointment delivery, pharmaceutical formulation, emulsion delivery, etc., can solve the problems of demulsification, unstable cream, rough paste, etc. Good transdermal absorption and little change in consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The ingredients and weight proportions of the self-emulsifying terbinafine hydrochloride cream prescription of the present invention are: terbinafine hydrochloride 10g, TEFOSE63 (polyethylene glycol-7 stearate) 140g, Span 8030g, light Liquid paraffin 20g, glyceryl monostearate 20g, purified water 780g.

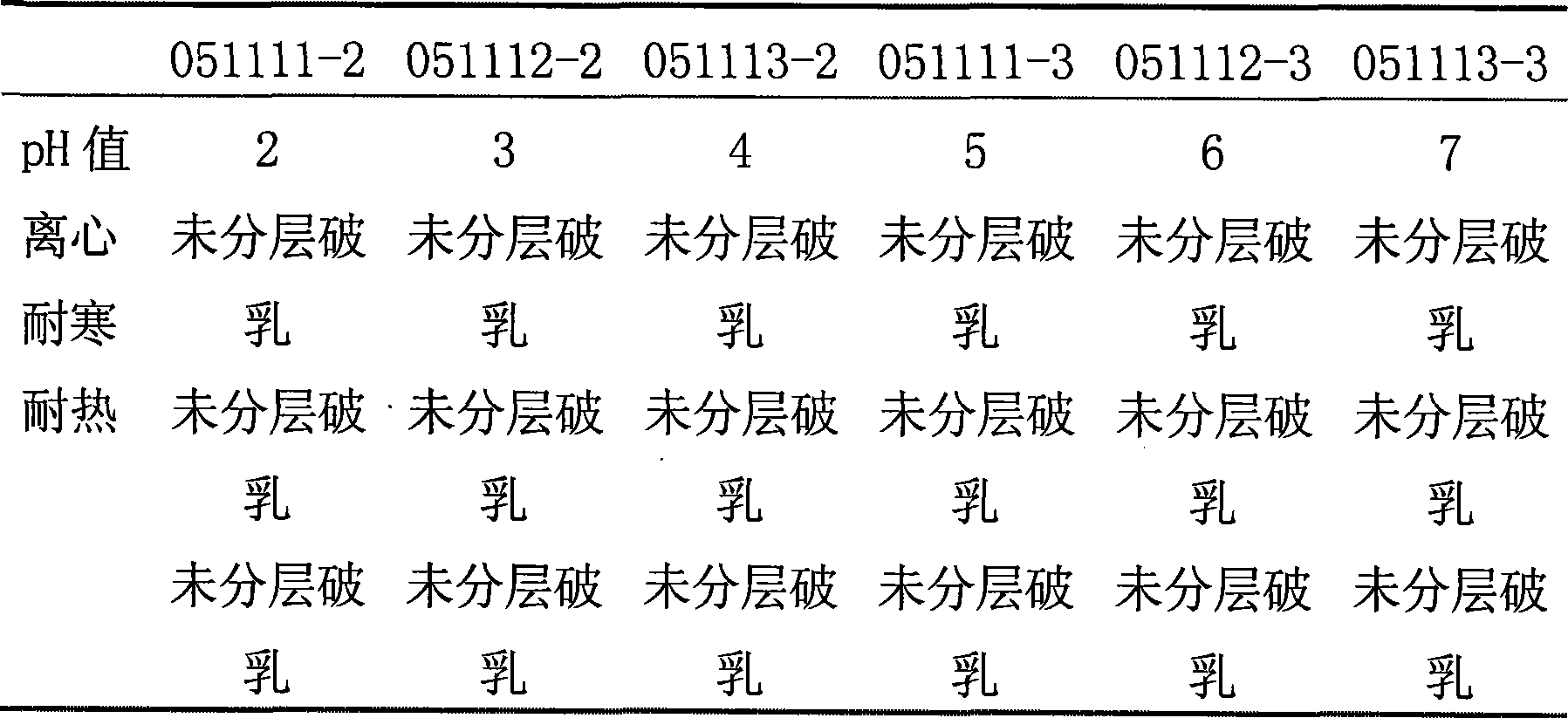

[0038] Heat the polyethylene glycol-7 stearate, glyceryl monostearate, Span 80, light liquid paraffin and purified water in the above prescription to 75°C-80°C, and wait until the components are completely dissolved Continue to stir rapidly for 30 minutes to 45 minutes, and cool to about 40°C (can be 30°C to 50°C). Keep this temperature, add terbinafine hydrochloride, continue to stir evenly, evacuate, continue to stir and cool to room temperature, and make 1000g of self-emulsified terbinafine hydrochloride cream, and the pH of the cream at this time is about 2-6 .

Embodiment 2

[0040] The ingredients and weight proportions of the self-emulsifying terbinafine hydrochloride cream prescription of the present invention are: terbinafine hydrochloride 30g, TEFOSE63 (polyethylene glycol-7 stearate) 60g, Span 8010g, light Liquid paraffin 10g, glyceryl monostearate 10g, purified water 880g.

[0041] Heat the polyethylene glycol-7 stearate, glyceryl monostearate, Span 80, light liquid paraffin and purified water in the above prescription amount to 65°C-80°C, and wait until the components are completely dissolved Continue to stir rapidly for 10-40 minutes, and cool to about 50°C-60°C. Keep this temperature, add terbinafine hydrochloride, continue to stir evenly, add an appropriate amount of triethanolamine to adjust the pH value between 4-6, vacuumize, continue to stir and cool to room temperature, and make 1000g self-emulsifying terbinafine hydrochloride cream . In the preparation process, triethanolamine is used to adjust the pH value of the preparation, an...

Embodiment 3

[0043] The ingredients and weight proportions of the self-emulsifying terbinafine hydrochloride cream prescription of the present invention are: terbinafine hydrochloride 5g, TEFOSE63 (polyethylene glycol-7 stearate) 180g, Span 8060g, light Liquid paraffin 40g, glyceryl monostearate 50g, purified water 665g.

[0044] Heat the polyethylene glycol-7 stearate, glyceryl monostearate, Span 80, light liquid paraffin and purified water in the above prescription to 75°C-95°C, and wait until the components are completely dissolved Continue to stir rapidly for 40-60 minutes, and cool to 20°C-30°C. Keep this temperature, add terbinafine hydrochloride, continue to stir evenly, add an appropriate amount of triethanolamine to adjust the pH value between 4-6, vacuumize, continue to stir and cool to room temperature, and make 1000g self-emulsifying terbinafine hydrochloride cream . In the preparation process, triethanolamine is used to adjust the pH value of the preparation, and the dosage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com